From automotive gears to consumer zippers, nylon injection molding transforms nylon plastic into precise, durable components. In this article, we will explore what nylon is, why it is favored in injection molding, the types of nylon used, the molding process itself, mold design considerations, advantages and disadvantages, and common applications.

What is Nylon?

Nylon, a synthetic polyamide, is a thermoplastic marvel developed by DuPont in 1935. Formed through condensation polymerization of diamines and dibasic acids or ring-opening of lactams, nylon’s molecular structure—rich in amide bonds—delivers exceptional mechanical and chemical properties. Its high tensile strength, toughness, and abrasion resistance make it a cornerstone of nylon molding. Yet, its hygroscopic nature, absorbing 2–8% moisture, demands careful handling to ensure dimensional stability in nylon plastic injection molding.

Nylon’s thermal stability, with melting points ranging from 220–270°C, supports high-temperature applications, while its chemical resistance to oils, fuels, and alkalis suits demanding environments. These attributes position nylon as a versatile material for nylon injection molding, from flexible cable ties to rigid automotive components.

Why Use Nylon Injection Molding?

Nylon injection molding service is favored for several reasons. First, nylon’s mechanical properties—such as high tensile strength, excellent abrasion resistance, and good impact toughness—make it suitable for components that must endure mechanical stress and wear. Second, nylon’s chemical resistance enables parts to withstand exposure to oils, fuels, and solvents, which is critical in automotive and industrial applications. Third, the injection molding process itself offers high precision and repeatability, allowing complex shapes with fine details to be produced efficiently and cost-effectively in large volumes. Furthermore, glass-filled nylon injection molding improves performance by reinforcing the material, which is especially beneficial for structural components requiring enhanced rigidity.

Types of Nylon Used in Injection Molding

Understanding the different types of nylon used in injection molding helps in selecting the right material for specific applications:

Nylon 6 (PA6): Known for its excellent toughness and impact resistance, nylon 6 absorbs moisture more readily, which can affect dimensional stability. It is widely used in nylon plastic injection molding for parts requiring good wear resistance and flexibility.

Nylon 12 (PA12): Exhibits very low moisture absorption, excellent dimensional stability, and high flexibility. It is also highly resistant to chemicals and impact. It is frequently used in automotive fuel lines, pneumatic tubing, medical devices, and electrical insulation.

Nylon 66 (PA66): This variant has a higher melting point and better heat resistance than PA6, making it suitable for components exposed to elevated temperatures. Its strength and stiffness are superior, but it is less flexible.

Glass Filled Nylon: By incorporating glass fibers (typically 15-40%), glass-filled nylon injection molding significantly enhances mechanical properties such as tensile strength, stiffness, and dimensional stability. This composite material is common in automotive parts, electrical housings, and industrial machinery.

Other Modified Nylons: These include flame-retardant nylons, impact-modified nylons, and nylons with additives to reduce moisture absorption or improve UV resistance, tailored for specialized needs.

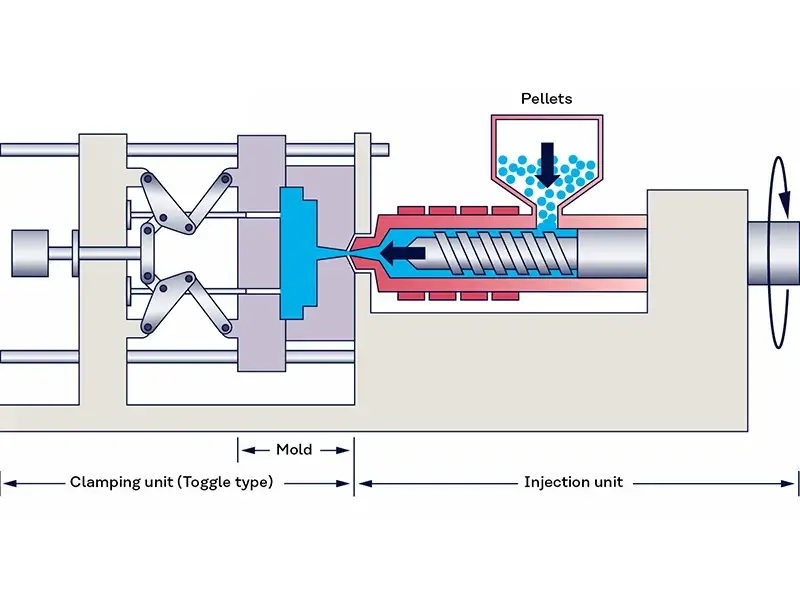

The Nylon Injection Molding Process

Nylon injection molding involves several critical steps to ensure high-quality parts:

- Material Preparation and Drying: Nylon is hygroscopic, meaning it absorbs moisture from the environment. Moisture can cause defects like bubbles, poor surface finish, and reduced mechanical strength. Therefore, drying nylon resin to below 0.2% moisture content is essential before molding, typically at 80-120°C for several hours.

- Melting and Injection: The dried nylon pellets are fed into the injection molding machine’s barrel, where they are heated above their melting point (around 220-290°C, depending on the type). The molten nylon is then injected into a mold cavity under high pressure (commonly between 60-120 MPa). For glass-reinforced nylon, higher temperatures and pressures may be necessary due to increased viscosity.

- Cooling and Solidification: Once injected, the nylon cools and crystallizes inside the mold. Mold temperature control (ranging from 30°C for unreinforced nylons to 90-100°C for reinforced grades) influences crystallinity, shrinkage, and mechanical properties. Efficient cooling channels in the mold help maintain uniform cooling and reduce cycle times.

- Ejection: After solidification, ejector pins release the molded part. Mold design must accommodate nylon’s shrinkage and include draft angles to facilitate easy ejection without damaging the part.

- Post-Processing: Depending on the application, parts may undergo trimming, annealing, or surface finishing. Quality inspection ensures dimensional accuracy and the absence of defects.

Here is a table to show the different nylon type properties details, and injection molding process conditions:

| Nylon Type | Nylon 6 | Nylon 66 | Nylon 12 | Glass Filled Nylon | Modified Nylon |

|---|---|---|---|---|---|

| Drying Temperature (°C) | 80-90 | 80-100 | 70-80 | 80-110 | Not specified (depends on additives) |

| Drying Time (hours) | 4-6 | 6-8 | 3-4 | 4-6 | Not specified (depends on additives) |

| Melting Temperature Range (°C) | 220-260 | 260-280 | 180-220 | 240-285 | Not specified (depends on formulation) |

| Injection Pressure Range (MPa) | 50-100 | 60-120 | 40-80 | 80-130 | Not specified (depends on viscosity) |

| Mold Temperature (°C) | 80-100 | 90-110 | 60-80 | 90-110 | Not specified (depends on additives) |

| Cooling Time (seconds) | 20-40 | 30-50 | 15-30 | 40-70 | Not specified (depends on formulation) |

| Shrinkage Compensation | 1.5–2% (allowance for shrinkage) | 1–1.5% (lower than Nylon 6) | 1.0–1.5% (lower due to flexibility) | 0.3–0.7% (shrinkage reduced by glass fibers) | 0.5–1.2% (depends on modifiers) |

| Mold Material | Standard tool steel (e.g., P20) | Heat-resistant steel (e.g., H13) | Standard tool steel (e.g., P20) | High hardness wear-resistant steel (e.g., S7) | Corrosion-resistant coatings depending on additives |

| Surface Treatment | Polished to Ra 0.2 μm | Chrome plating (anti-stick) | Polished to Ra 0.4 μm (flexible surface) | Nitriding (resist glass fiber wear) | Teflon coating (chemical resistance) |

Nylon Injection Molding Design Guideline and Considerations

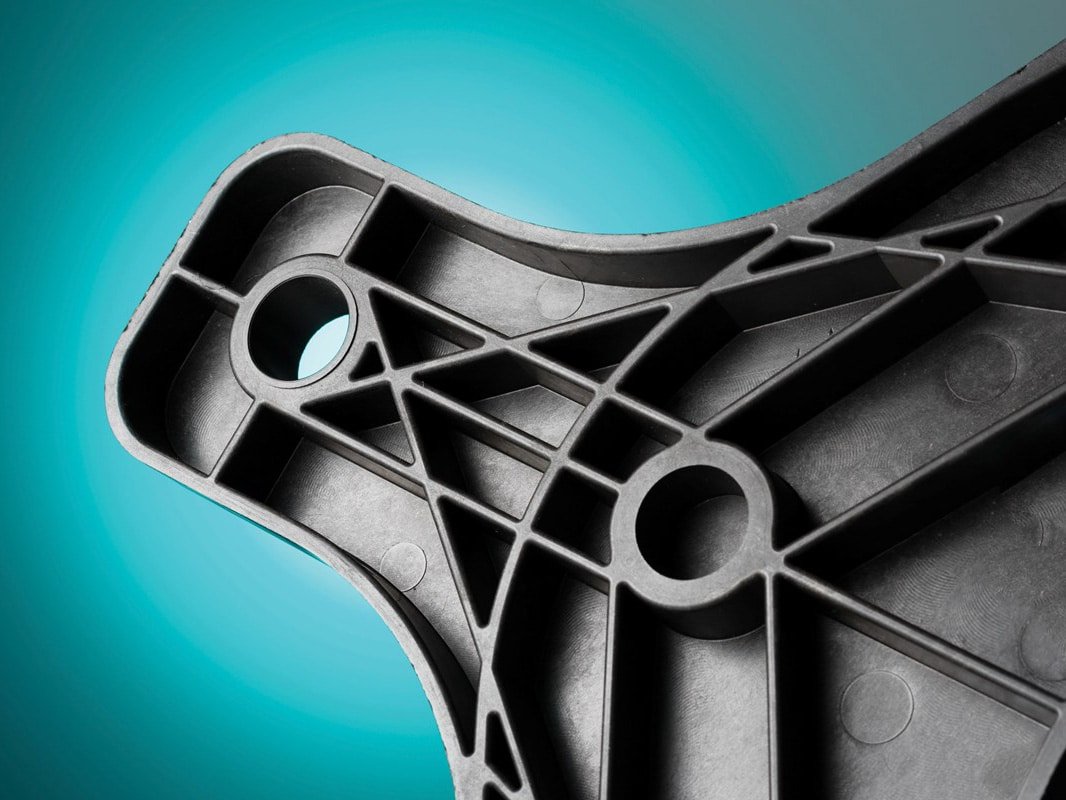

To ensure high-quality nylon injection molded parts, designers must account for both general molding principles and nylon-specific design considerations.Wall Thickness

Due to nylon’s low melt viscosity, This is slightly thinner than most other injection molding materials. The recommended wall thickness is between 0.030 and 0.115 inches (0.76 – 2.92 mm) for nylon injection molded parts. Avoid walls thicker than 6 mm, as they can lead to internal voids, sink marks, and longer cycle times. When nylon injection molding, maintain uniform wall thickness to avoid defects like sink, warp, or short shots. If uniform thickness isn’t possible, ensure gradual transitions (no more than 10% to 15% change in thickness between adjacent walls) to minimize stress concentrations and ensure consistent cooling and shrinkage.Draft Angles

Applying a draft angle of 0.5° to 1° per side is recommended to shorten cycle times and reduce tool wear. For textured surfaces, increase the draft angle by 1° per 0.025 mm of texture depth to ensure smooth ejection.Corner Radii

Avoid sharp corners; use round corners. Use corner radii larger than 0.5 mm. For optimal performance, radii should be equivalent to 75% of the nominal wall thickness to enhance fatigue resistance and improve moldability.Material Drying Before Molding

Nylon absorbs moisture, so it must be dried before injection molding to prevent processing issues.Pay Attention to Shrinkage

Nylon has a higher shrinkage rate than most thermoplastics, which can challenge dimensional tolerances. Controlled shrinkage allows for consistent tolerances, making nylon suitable for precision components like gears and bearings.Proper Add Fillers

Adding glass fibers (e.g., 30% to 50%) enhances mechanical and thermal properties but increases brittleness and tool wear. Use harder steel molds for glass-filled nylon to mitigate abrasiveness.Additional Design Tips

Bosses and Standoffs: Ensure proper draft angles for these features to avoid ejection issues. Tall bosses may require deeper molds or vent holes to prevent short shots. Ribs and Gussets: Use these to reinforce parts while maintaining thin walls to reduce material usage and cycle times.Advantages and Disadvantages of Nylon Injection Molding

Nylon injection molding offers compelling benefits but also presents challenges that require careful management.Advantages of Nylon Injection Molding:

High Strength: Tensile strength of 50–150 MPa (with fillers) supports robust parts like gears. Chemical Resistance: Resists fuels, oils, and alkalis, ideal for automotive and industrial applications. Low Friction: Coefficient of 0.2–0.3 suits moving parts in nylon 6 injection molding. Recyclability: Supports sustainable manufacturing, reducing waste.Disadvantages of Nylon Injection Molding:

Hygroscopicity: 2–8% water absorption affects dimensional stability, requiring drying. Poor UV Resistance: Unmodified nylon degrades outdoors unless UV-stabilized. Acid Sensitivity: Susceptible to strong acids and oxidizers. Process Sensitivity: Precise control is needed to avoid defects like sink marks.Common Applications of Nylon Injection Molding

Nylon has various types, and nylon injection molding serves diverse industries, such as automotive, electronics, consumer goods, industrial, aerospace plastic injection moldingparts, etc. The applications include:

- Gears

- Bearings

- Fuel tanks

- Structural components

- Connectors

- Cable ties

- Switch terminals

- Zippers

- Racket strings

- Pulleys

- Impellers

- Conveyor belts

- Bushings

- Fittings