Polyoxymethylene (POM) is one of the plastic materials that has many benefits when it comes to POM CNC machining parts. It is a versatile thermoplastic known for its exceptional strength, low friction, and high dimensional stability.

What is POM and Why CNC Machining?

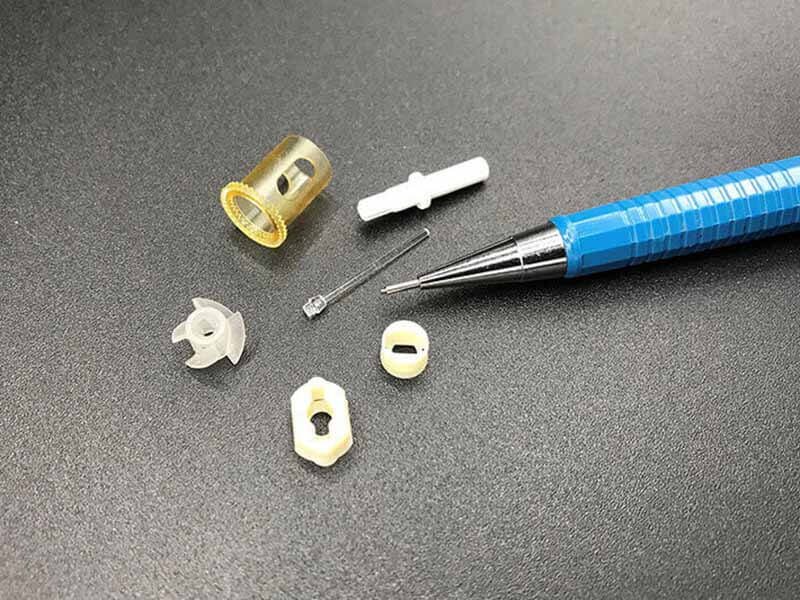

POM is a crystalline plastic known for its high mechanical strength, stiffness, and resistance to wear. It is often used in demanding applications that require precision and long-lasting durability. POM is particularly favored for its low friction, which makes it ideal for moving parts such as gears, bearings, and bushings.

CNC machining is the ideal process for fabricating POM CNC components due to its ability to produce parts with high precision. The material’s superior machinability, combined with the capability of CNC machines to cut intricate shapes and maintain tight tolerances, makes it suitable for custom, low-to-medium volume production. Through the use of computer-controlled machine tools, can achieve repeatable accuracy and high-quality finishes, ensuring that each part meets the required specifications without excessive material waste.

Types of POM and Their Properties

There are two primary types of POM used in CNC machining: homopolymer POM and copolymer POM.

Homopolymer POM

This is the most commonly used type of POM in CNC machining. It is characterized by high mechanical strength, low wear rates, and excellent chemical resistance. Homopolymer POM has a higher stiffness and tensile strength compared to its copolymer counterpart, making it ideal for applications that require rigid and strong components.

Copolymer POM

Copolymer POM contains a small amount of a second monomer, which improves the material’s resistance to environmental stress cracking and increases its impact resistance. While it has slightly lower strength than homopolymer POM, it is more chemically resistant and more stable when exposed to moisture, making it suitable for more demanding environments.

Both types of POM offer low friction, high wear resistance, and low moisture absorption, making them ideal for parts that experience continuous motion or contact with other materials.

POM CNC Machining Process and Techniques for POM

CNC machining of POM involves a series of processes designed to shape the material into precise components. Some of the most common CNC machining techniques used for POM include turning, milling, and drilling.

- Turning: This technique is typically used to create cylindrical components, such as shafts or bushings. During turning, the POM workpiece is rotated while a cutting tool moves across the surface to remove material. The precision of CNC turning allows for the production of parts with tight tolerances.

- Milling: CNC milling is used to create complex shapes, such as gears, brackets, and housings. Milling machines use rotating cutting tools to remove material from the POM workpiece, allowing for the creation of intricate designs and precise dimensions.

- Drilling: Drilling is used to create holes in POM CNC components. CNC drills can make holes with high accuracy, ensuring that the dimensions and placements meet the required specifications. Drilling can be performed on both small and large workpieces, with the ability to produce holes of various sizes.

CNC Machining Process and Key Considerations for POM

CNC machining of POM involves precise operations such as turning, milling, and drilling, each requiring specific techniques and careful considerations to achieve high-quality results.

POM CNC Turning

This technique is typically used to create cylindrical components, such as shafts or bushings. During turning, the POM workpiece is rotated while a cutting tool moves across the surface to remove material.

Key Considerations:

- Use sharp carbide tools to avoid melting or deformation caused by friction.

- Maintain appropriate cutting speeds and feed rates; excessive speed can generate heat, causing warping.

- Avoid deep cuts in a single pass; multiple lighter passes reduce stress on the material.

POM CNC Milling

POM CNC milling is used to create complex shapes, such as gears, brackets, and housings. Milling machines use rotating cutting tools to remove material from the POM workpiece, allowing for the creation of intricate designs and precise dimensions.

Key Considerations:

- Select cutting tools with proper geometry to minimize material build-up and surface chipping.

- Keep spindle speeds moderate and use controlled feed rates to maintain surface finish quality.

- Ensure the workpiece is securely clamped to prevent vibration or movement during cutting.

POM CNC Drilling

Drilling creates holes in CNC POM components, which can range from small to large diameters. CNC drills offer consistent accuracy for hole placement and size.

Key Considerations:

- Use sharp drills with a proper point angle to avoid cracking or tearing of the material.

- Apply minimal pressure and proper feed to reduce heat generation and burr formation.

- Consider using peck drilling for deep holes to avoid material binding or chip accumulation.

POM CNC Machining Tolerances, Surface Finishes, and Cost Considerations

Tight Tolerance

One of the main advantages of CNC machining for POM is the ability to achieve tight tolerances. For most POM applications, tolerances of ±0.1 mm are typical, but tighter tolerances can be achieved with careful machine setup and precise cutting techniques.

Surface Finishes Treatment

Surface finishes for POM components can range from rough to smooth, with polished surfaces often required for parts that will be used in consumer-facing applications. The desired finish will depend on the intended use of the part and the specific requirements of the customer.

CNC Machining Cost

While CNC POM machining provides high precision, it is generally more expensive than other manufacturing methods, such as injection molding, especially for high-volume production. The cost is influenced by factors such as the complexity of the part, the number of operations required, and the time it takes to machine each component. However, for low to medium-volume production runs or highly customized parts, CNC machining remains a cost-effective solution.

Typical Applications of CNC-Machined POM Components

POM is used extensively in industries where high-performance, durable parts are required. Some common applications for CNC-machined POM include:

- Automotive Industry: Gears, bearings, bushings, car interior parts, dashboard components, door handles, and seat adjusters.

- Medical Devices: POM surgical instruments, dental equipment, and implantable devices.

- Electronics: POM connectors, housings, and other electronic components.

- Consumer Goods: POM appliances, toys, and sporting equipment.

Conclusion

POM CNC machining provides a method for producing reliable parts across industries. By understanding material types, properties, processes, and considerations, we can achieve desired outcomes efficiently. Jiangzhi offers customized POM parts manufacturing. Welcome to contact us and get a custom cnc machining solution.

Your One-Stop Manufacturing Partner

FAQ

1. What is the tightest tolerance POM CNC machining can achieve?

Typical tolerances are around ±0.1 mm, but tighter tolerances can be achieved with careful setup and precision tooling.

2. Is coolant necessary when machining POM?

Coolant is not always required. Air cooling or minimal coolant is sufficient to prevent heat buildup and material distortion.

3. Is POM suitable for machining complex 3D shapes?

Yes, POM can be machined into complex 3D geometries using CNC milling, turning, and drilling. Its machinability makes it ideal for intricate designs.

4. How to choose a POM grade for different applications?

Choose homopolymer POM for higher strength and stiffness, and copolymer POM for better chemical resistance and impact performance. Consider the mechanical and environmental requirements of the application.