TPE injection molding service has become a popular manufacturing technology for producing flexible, durable, and complex polymer parts used across numerous industries. Whether as standalone injection-molded components or as overmolded layers integrated with rigid plastics, TPE materials bring a unique combination of elastomeric properties and thermoplastic processability to the table. In this article, we will explore the deatiled TPE injection molding process and materials properties.

What is TPE Material?

Thermoplastic Elastomer is a type of block copolymer or physical blend with a phase-separated structure. Its molecular chain contains both hard and soft segments, combining the flexibility of rubber and the processability of thermoplastics. It can be melted and formed multiple times and recycled. It has excellent elongation, tear resistance and wear resistance, and can resist grease, some solvents and ultraviolet rays. However, its heat resistance is generally only 100-150°C, and it is prone to permanent deformation after long-term pressure. Some grades also need to be dried before processing, and the cost is higher than that of ordinary plastics.

Different Types of TPE Materials

TPEs encompass various subtypes. Here’s a breakdown:

- TPU (Thermoplastic Polyurethane): Known for excellent abrasion resistance, elasticity, and transparency.

- TPV (Thermoplastic Vulcanizate): Mimicking vulcanized rubber, TPV offers enhanced heat and chemical resistance.

- TPO (Thermoplastic Olefin): Often polyethylene or polypropylene-based blends, lightweight and cost-effective, provides moderate elasticity but lower heat tolerance.

- TPS/SBC (Styrenic Block Copolymers): Soft and easily colored, yet they falter in high-heat or solvent-heavy scenarios.

- TPEE/COPE (Thermoplastic Polyester Elastomer):With superior fatigue resistance and rigidity, It’s pricier.

- PEBA (Polyether Block Amide): Flexible, breathable, and lightweight elastomers even at low temperatures.

What is TPE Injection Molding?

TPE injection molding is a manufacturing technique where molten TPE is injected into a mold cavity under high pressure, cooled, and ejected as a finished part. This method leverages the thermoplastic nature of TPE, allowing for rapid production cycles without the need for vulcanization. Compared to traditional rubber molding, TPE injection offers shorter cycle times, often under a minute, and minimal waste.

How to Process Thermoplastic Elastomers for Injection Molding?

Material Preparation and Drying

TPE pellets, especially hygroscopic types like TPU, must be dried in a dehumidifying hopper at 60-80°C for 2-4 hours to reduce moisture below 0.05%.

Melting and Injection

The TPE is fed into a screw-type injection machine, heated in zones from 160°C at the hopper to 230°C at the nozzle. Injection occurs at proper pressures, with a multi-stage speed profile: slow initially to vent air, then faster to fill the cavity completely.

Cooling and Ejection

Cooling follows, with mold temperatures maintained at 30-70°C to promote even solidification and minimize warpage. Finally, the part is ejected using pins or air blasts, inspected for defects like flash or sink marks, and post-processed if needed.

Key Considerations in TPE Injection Molding

- Temperature control is very important; overheating degrades the material, while underheating causes short shots.

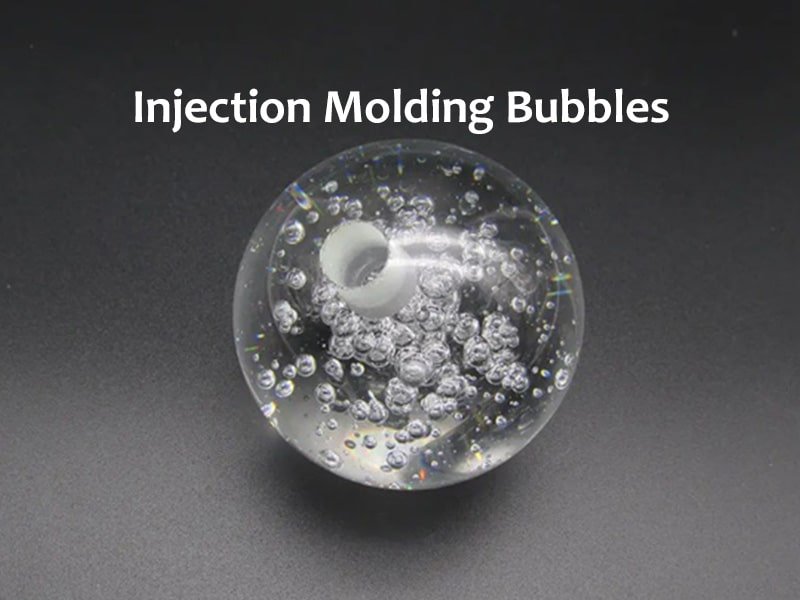

- Mold venting prevents trapped gases from forming voids.

- Wall thickness should be uniform (1-3mm ideal) to avoid differential cooling stresses.

- Draft angles of at least 1° facilitate ejection, and gate placement, preferably at thick sections, reduces shear stress.

- For overmolding in thermoplastic elastomer injection molding, ensure substrate compatibility; mechanical interlocks or adhesives boost adhesion.

- Monitor screw speed to avoid excessive shear heating, and always prototype to fine-tune parameters.

Applications of TPE Injection Molding

TPE injection molding is pervasive across industries where flexibility, durability, and tactile properties matter. Typical applications include:

- Automotive: Dashboard components, seals, gaskets, soft-touch grips, protective moldings.

- Medical devices: Flexible tubing, seals, cushions, ergonomic handles.

- Consumer products: Soft-touch overmolds on electronics, toothbrush grips, sports equipment.

- Footwear: Soles and midsoles using flexible elastomers.

- Electronics: Cable sheathing, connectors, vibration dampening pads.

- Packaging: Flexible caps and seals with elastic closure.

Advantages of TPE Injection Molding Process

TPE injection molding boasts numerous advantages that propel its adoption.

Versatile Material Properties

TPEs blend rubber-like flexibility with thermoplastic processability, offering customizable elasticity, strength, and resistance to chemicals, temperature, and UV.

Recyclability

TPEs can be melted and reprocessed without chemical crosslinking, minimizing waste and supporting sustainable manufacturing compared to thermoset elastomers.

Cost-Effectiveness

Low material waste, affordable TPE options, and compatibility with standard injection molding machines ensure economical prototyping and high-volume production.

Design Flexibility

Enables complex geometries, soft-touch features, and intricate designs like seals or grips, with support for advanced techniques like overmolding and multi-shot molding.

Durability

Offers excellent resistance to wear, tear, and impact, with specific formulations providing high tensile strength for demanding environments.

Rapid Production

Supports fast prototyping and production, with parts deliverable in as little as one day, ideal for industries requiring quick turnarounds.

Wide Applications

Highly versatile for automotive, medical, and consumer electronics, with tailored TPE formulations meeting specific performance and environmental needs.

Disadvantages of TPE Injection Molding Manufacturing Process

Higher Material and Tooling Costs

Specialized TPE grades like TPU are expensive, and complex molds require significant investment, making low-volume runs less cost-effective.

Processing Sensitivity

Strict temperature and moisture control is necessary; deviations can cause surface defects, shrinkage issues, or dimensional instability.

Limited Resistance

TPE softens under heat and may degrade when exposed to aggressive solvents, restricting use in harsh environments.

Overmolding & Environmental Challenges

Adhesion problems in overmolding and sensitivity to humidity or climate conditions can complicate production.

Choosing Jiangzhi as Your TPE Injection Molding Manufacturer

TPE injection molding combines rubber elasticity with thermoplastic efficiency. Jiangzhi, an injection molding manufacturer, specializes in custom TPE injection molding and overmolding, using advanced facilities and expert engineers to deliver high-quality, cost-effective products. Contact Jiangzhi to turn your ideas into reliable thermoplastic elastomer solutions.