Metal Material

Metal Material Overview

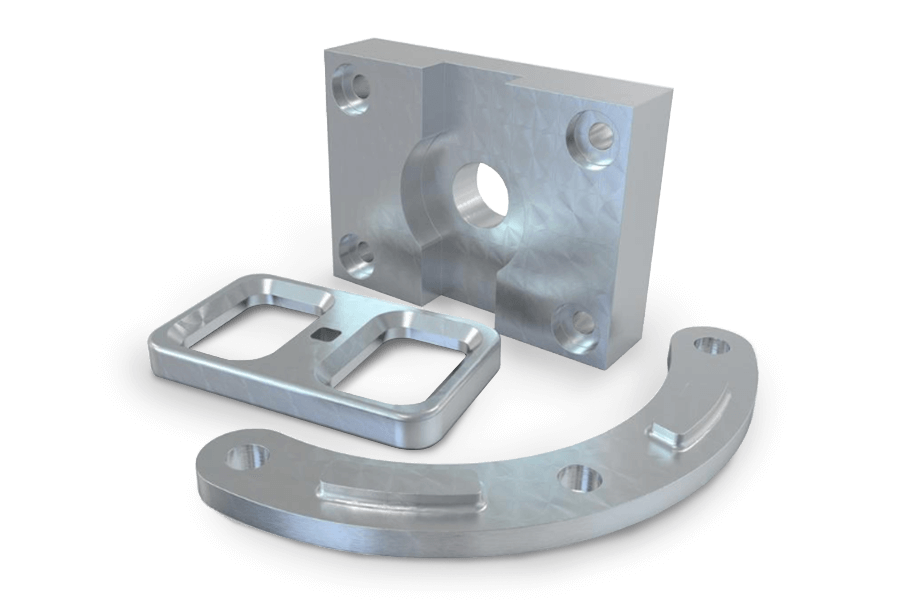

Metal materials are used in many industries for their strength, durability, and versatility. Steel, aluminum, and stainless steel each suit different needs. Here, you can quickly find the right metal for your project and make smart choices for performance, cost, and reliability.

In choosing the suitable metal for your custom CNC metal parts project, meticulous attention to characteristics such as strength, hardness,corrosion resistance, and thermal conductivity ensures optimal performance. Considering factors like operating environment, load conditions, and long-term wear allows for precise material selection, enhancing durability, reliability, and overall functionality. Selecting the right metal upfront can also reduce manufacturing challenges and costs. For more details or guidance on choosing the best material for your application, please contact us.

Common CNC Metal Materials We Offer:

Material Modification

At Jiangzhi, we specialize in enhancing cnc materials to elevate your project outcomes. Our material modification service allows you to tailor base materials, optimizing properties for superior performance. Whether you require improved strength, enhanced thermal stability, or specific characteristics, we collaborate with you to deliver customized solutions.

Advantages of Plastic Material in Manufacturing

Lightweight

Durability

Corrosion Resistant

Insulating Properties

CNC Materials Parts in Different Industries

FAQs About Metal CNC Materials Related Problems

When selecting materials, the following factors should be considered:

- Performance requirements: For example, high temperature resistance, corrosion resistance, high strength and so on.

- Difficulty of processing: Some metals are more difficult to process and may require special tools and techniques.

- Cost control: The cost of different metals varies greatly, choose the right material according to the budget.

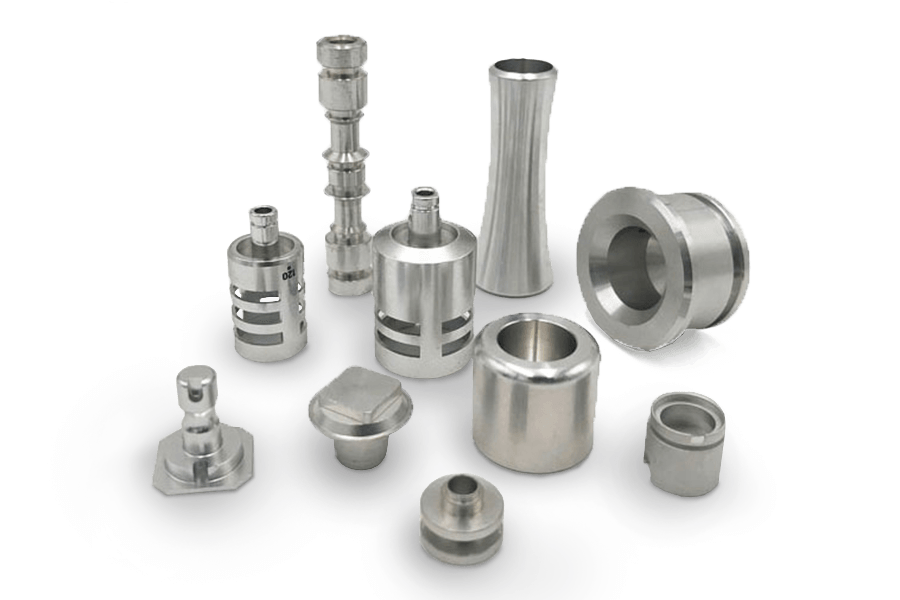

CNC machining service is suitable for various metal CNC materials, including aluminum alloy, stainless steel, titanium alloy, copper alloy, nickel alloy, tool steel, etc. Choosing the right metal material depends on the use needs and processing requirements of the parts.

Of course you can! CNC machining is very suitable for custom production. Whether prototyping or small batch production, we can tailor the processing to your requirements.

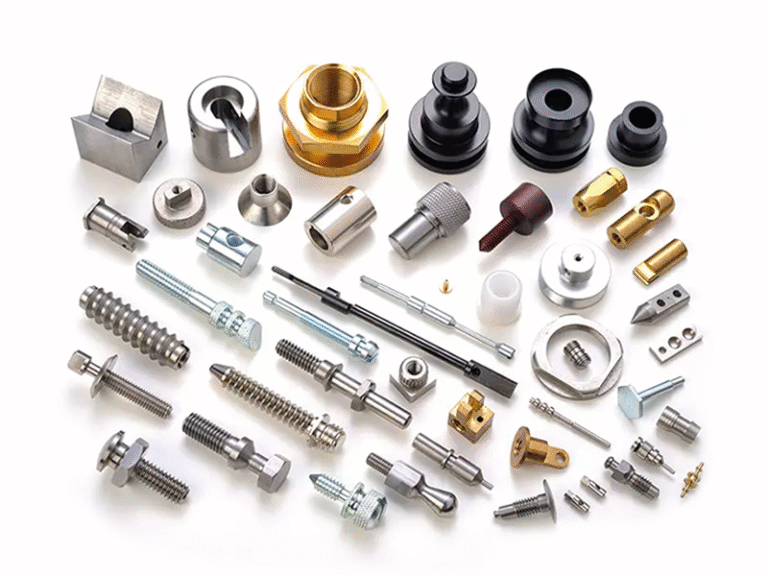

Steel: high strength, wear resistance, suitable for construction, machinery manufacturing and other fields.

Aluminum alloy: light weight, strong corrosion resistance, but low strength, suitable for occasions that need to lose weight.

Stainless steel: strong corrosion resistance, high strength, widely used in food, chemical, medical equipment and other fields.

Titanium alloy: light weight, high strength, high temperature resistance, corrosion resistance, suitable for aerospace and medical industries.

Copper alloy: Good conductivity, corrosion resistance, widely used in electrical and piping systems.

Popular Post

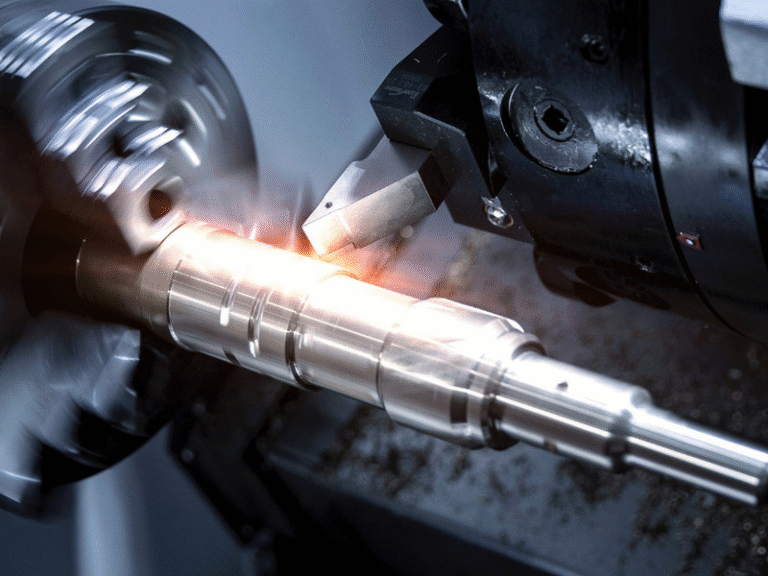

What Are CNC Turning Parts and How to Design Them for Better Performance?

CNC turning parts can meet tight tolerances and complex geometries. In this article, we will learn the CNC turning process,

CNC Machined Steel Guide

In modern manufacturing, the demand for high-quality, durable, and precisely engineered metal components continues to grow. Among various materials, CNC

Understanding Aluminum CNC Machining Processes

Aluminum CNC machining is a cornerstone of modern manufacturing, enabling high-precision, complex parts across industries such as aerospace, automotive, electronics,