Nylon Injection Molding

PA injection molding achieve lightweight, durable components with 20-40% cost savings over metal. From Jiangzhi get custom nylon molding solutions with fast turnaround.

What is Nylon Injection Molding?

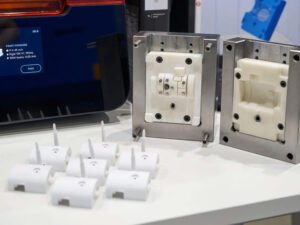

Injection nylon molding is a widely used manufacturing process for producing strong, durable plastic parts found in everyday products—from packaging to consumer goods. In this process, nylon granules are heated and injected under high pressure into a custom mold, where they take the shape of the desired component. Once cooled, the mold opens and the nylon part is released, ready for use. This method is ideal for high-volume production and offers excellent repeatability, precision, and material efficiency.

When you choose Jiangzhi for nylon injection molding parts, we begin by reviewing your product design through thorough DFM analysis to ensure it’s optimized for injection molding. We then develop a custom mold tailored to your part—or use existing molds when suitable to save time and cost. Throughout the process, we carefully control nylon material drying, melting, and high-pressure injection to produce parts with consistent quality. After molding, the parts undergo cooling, ejection, strict quality inspection, and any necessary post-processing. From DFM review to final delivery, we provide seamless, full-process support focused on efficiency, quality, and meeting your production needs.

| Parameter | Recommended Range |

|---|---|

| Wall Thickness | 0.8mm - 3.5 mm |

| Maximum Part Size | 2000mm x 1500mm x 1000mm |

| Minimum Feature Size | 0.4mm-0.8mm |

| Tolerances | ±0.05mm - ±0.3mm |

Common Nylon Materials & Properties

Nylon (Polyamide) is a versatile engineering thermoplastic renowned for its exceptional strength-to-weight ratio, heat resistance, and wear performance. We offer a variety of nylon (polyamide, PA) materials tailored to different application needs—from basic structural parts to high-performance components in demanding environments. Below are some of the commonly used PA materials available through our injection molding services:

- PA (Blue): Offers reliable mechanical strength and fatigue resistance, making it a good fit for general-purpose structural parts.

- PA6 + 15% Glass Fiber (Black):Reinforced with 15% glass fibers to increase stiffness and dimensional stability. Ideal for components exposed to moderate mechanical loads.

- PA6 + 30% Glass Fiber (Black): Provides enhanced strength and rigidity for high-stress applications. Well-suited for technical parts requiring both mechanical performance and thermal resistance.

- PA66 (Natural): Known for its higher tensile strength and thermal stability compared to PA6. Recommended for parts exposed to elevated temperatures over time.

- PA66 (Black, UV-Resistant): Combines the mechanical and thermal benefits of natural PA66 with added UV resistance, making it suitable for outdoor or sunlight-exposed environments.

| Property | Density | Tensile Strength | Flexural Strength | Impact Strength (Unnotched) | Heat Deflection Temp (0.45 MPa) |

|---|---|---|---|---|---|

| PA6 | 1.12 - 1.15 g/cm³ | 70 - 90 MPa | 100 - 120 MPa | 50 - 100 kJ/m² | 180 - 200℃ |

| PA12 | 1.01 - 1.02 g/cm³ | 45 - 55 MPa | 40 - 50 MPa | 120 – 200 kJ/m² | 140 – 160°C |

| PA66 | 1.12 - 1.15 g/cm³ | 80 - 95 MPa | 110 - 140 MPa | 60 - 120 kJ/m² | 190 – 210°C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

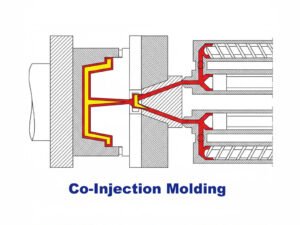

Related Process

Need Reliable Nylon Injection Molding?

Strong, Wear-Resistant Nylon Injection Moulding – Custom Solutions for Your Needs.

Advantages & Disadvantages of Nylon Injection Molding

Nylon injection moulding is a popular manufacturing method known for its durability, cost-effectiveness, and reliable mechanical performance. As a versatile polyamide material, nylon is widely used across various industries for producing high-quality plastic parts. When selecting materials for injection molding, understanding the advantages and limitations of nylon is essential to optimize design, production efficiency, and end-use performance.

Advantages

- High durability and wear resistance – suitable for demanding applications.

- Lightweight yet strong – ideal for replacing metal parts.

- Cost-effective – cheaper than metals like aluminum.

- Excellent surface finish – results in parts that are smooth and easy to paint or coat.

- Reinforceable – compatible with fillers like fiberglass.

- Good chemical resistance – compatible with oils, greases, and fuels.

Disadvantages

- Moisture absorption – can affect dimensional stability and mechanical properties.

- Sensitive to humidity – performance may vary in high-humidity environments.

- Higher shrinkage rate – may require tighter mold tolerances.

- Requires careful drying before molding – to avoid defects during production.

Applications of Injection Molded Nylon

Injection molded nylon, renowned for its strength, durability, and heat resistance. Its capabilities produce lightweight, cost-effective components that often replace metals. Enhanced by reinforced and recycled variants, nylon also supports sustainable manufacturing, solidifying its role as a critical material in modern engineering solutions.

Automotive Industry

- Engine covers

- Fuel system components

- Nylon gears

- Plastic bushings

- Radiator end tanks

Electronics Industry

- Connectors

- Switch housings

- Circuit breaker components

- Insulating casings

- Battery cover/seal ring

Mechanical Equipment

- Gears

- Bearings

- Rollers

- Conveyor system components

- Machine housings

Medical Devices

- Surgical instrument handles

- Prosthetic components

- Medical tubing

- Breathing mask/connector

- Artificial joint pad

Jiangzhi PA Injection Molding Parts are Guaranteed

100% Satisfaction: Precision-molded nylon components engineered for superior strength, heat resistance, and unmatched durability – your toughest designs, transformed into lightweight, chemically resilient solutions. Where innovation meets endurance.

FAQs About Injection Nylon Molding

Absolutely. Just send us your CAD file or sample. Our engineering team will assess feasibility, suggest the right nylon grade, and provide design feedback if needed.

Performance is often improved by adding glass fiber to increase strength, using heat stabilizers to handle higher temperatures, and including lubricants to reduce friction—making parts stronger, more heat-resistant, and smoother in operation.

The typical wall thickness for PA (nylon) injection molded parts ranges from 1.5 mm to 3.5 mm. However, the ideal thickness depends on the part’s design, load requirements, and whether the material is reinforced. Uniform wall thickness is recommended to ensure proper flow and avoid defects like warping or sink marks.

Nylon naturally absorbs water, which can cause issues like bubbles, poor surface finish, or even part failure if not handled right. That’s why we always dry it properly before molding to make sure your parts come out strong and clean.

For new product mold, 2–4 weeks including samples. For repeat orders, 7–15 days depending on quantity and part complexity.