Rubber Material

Rubber Material Overview

Rubber Material is a material with high elasticity and plasticity, which is widely used in industrial and consumer products. According to the source, rubber can be divided into natural rubber (NR) and synthetic rubber two categories:

- Natural rubber (NR): Made from latex extracted from rubber trees, it has excellent elasticity, wear resistance, and tear resistance.

- Synthetic rubber: prepared by chemical synthesis methods, including many types.

At Jiangzhi, we help you select the right rubber for your project and can adjust base polymers to meet your specific performance requirements. Choosing a suitable material is crucial for your rubber molding project. Read our guide on how to select the rubber material.

Common Rubber Types We Offer

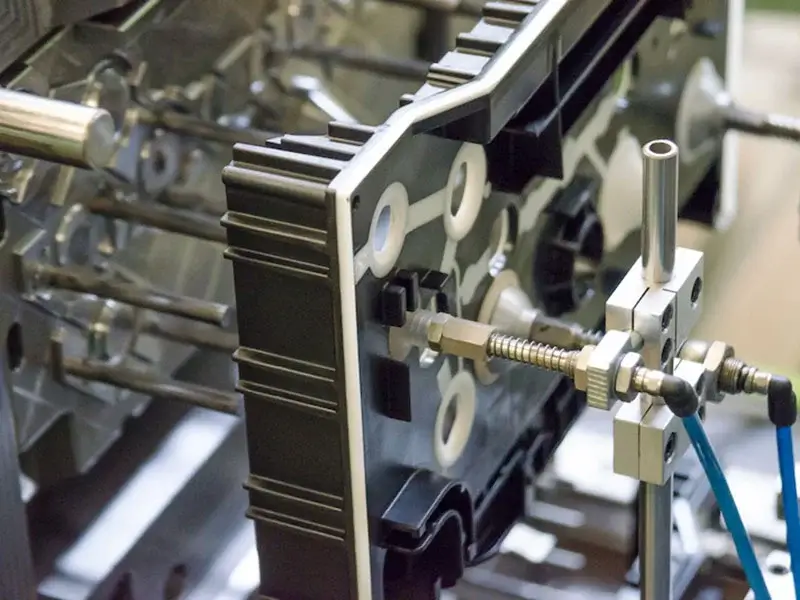

Rubber Compression Molding Material

- Natural Rubber (NR)

- Nitrile Rubber (NBR)

- Neoprene (CR)

- Styrene Butadiene Rubber (SBR)

- Ethylene Propylene Diene Monomer (EPDM)

- Silicone Rubber (MVQ)

- Butyl Rubber (IIR)

- Fluoroelastomers (FKM)

- Perfluoroelastomer (FFKM)

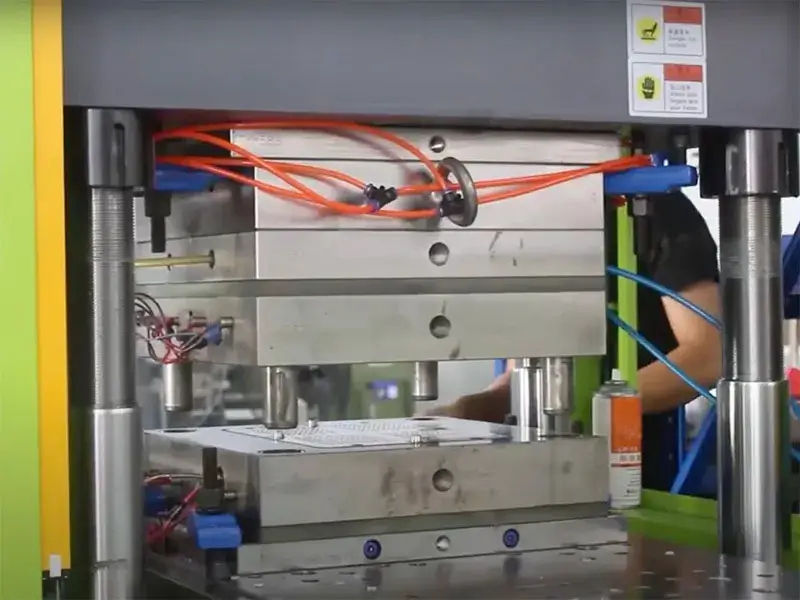

Rubber Injection Molding Material

- Natural Rubber (NR)

- Nitrile Rubber (NBR)

- Neoprene (CR)

- Styrene Butadiene Rubber (SBR)

- Ethylene Propylene Diene Monomer (EPDM)

- Silicone Rubber (MVQ)

- Butyl Rubber (IIR)

- Fluoroelastomers (FKM)

- Perfluoroelastomer (FFKM)

Rubber Heat Resistance Chart

| Material | Temperature Range (°C) | Oil Resistance (Vol. Swell %) ↓ Lower = Better | Weather / Ozone Resistance | Chemical Resistance | Chemical Resistance | Mechanical Strength (MPa / %) |

|---|---|---|---|---|---|---|

| NR (Natural Rubber) | -50 to +80 | 80–150% (Poor) | Poor | Poor | 20–25 MPa / 500–700% | 25–35% |

| NBR (Nitrile Rubber) | -30 to +120 | 0–30% (Excellent) | Fair | Fair | 12–20 MPa / 300–500% | 15–25% |

| CR (Neoprene) | -40 to +120 | 20–60% (Medium) | Good | Moderate | 10–20 MPa / 250–500% | 20–35% |

| SBR | -50 to +80 | 60–120% (Poor) | Fair–Poor | Poor | 10–20 MPa / 300–500% | 25–40% |

| EPDM | -55 to +150 | 80–150% (Poor) | Excellent (among best) | Excellent (among best) | 7–14 MPa / 300–600% | 20–35% |

| Silicone (MVQ) | -60 to +200 (up to 230°C short-term) | 40–80% (Average) | Excellent | Good | 7–12 MPa / 200–700% | 12–25% |

| IIR (Butyl Rubber) | -45 to +130 | 80–150% (Poor) | Good | Good | 7–14 MPa / 400–600% | 10–20% (Very good) |

| FKM (Fluoroelastomer) | -20 to +200 (up to 250°C short-term) | 0–15% (Outstanding) | Excellent | Excellent | 10–20 MPa / 150–300% | 10–20% (Excellent) |

| 10–20% (Excellent) | 0 to +320 (grade dependent) | 0–5% (Best in class) | Excellent | Exceptional (near universal) | 7–18 MPa / 150–300% | 5–12% (Best) |

Material Modification

Advantages of Rubber Material in Manufacturing

Exceptional Elasticity

Durability and Wear Resistance

Versatile Applications

Chemical and Temperature Resistance

The Application of Rubber Material

Automotive & Transportation

Industrial & Engineering

Medical & Healthcare

Household & Consumer Products

Jiangzhi Rubber Processing Service

Rubber Part in Different Industries

FAQs About Rubber Material Parts

Most rubber parts are made with tolerances around ±0.25–0.40 mm. For more precise applications, we can adjust the tooling and design to meet tighter requirements, so your parts fit perfectly.

If you need seals that keep their shape under long-term pressure, FFKM performs best (5–12%), with FKM and Butyl (IIR) also doing very well. We can help you choose based on your operating conditions and budget.

Absolutely! We can adjust rubber hardness from Shore A 20 to 90, so whether you need a soft, flexible seal or a firmer, durable gasket, we can tailor it to your exact needs.

For high-heat environments: FFKM works up to 300°C, FKM up to 250°C, and Silicone (MVQ) up to 230°C. We can help you pick the right one based on your temperature range, duration, and exposure conditions.

For oil and fuel, FKM and FFKM are top performers. NBR is a cost-effective option for less extreme conditions.

EPDM is ideal for long-term outdoor use, UV, and ozone resistance, while Silicone also holds up very well in sunlight and harsh weather.

Popular Post

What Is Rubber Flash on Rubber Parts and How to Remove It?

Rubber flash is a common rubber part defect during the manufacturing of molded rubber parts. It is often dismissed as

Rubber Compression Molding: Process, Mold Design & Comparison with Injection Molding

Rubber compression molding is a widely used manufacturing process for shaping rubber into precise, durable components for various industries. This

Key Rubber Parts Defects You Need To Know

Have you ever wondered about the most common rubber parts defects and how they could impact your projects? During the