Silicone Injection Molding

What is Silicone Injection Molding?

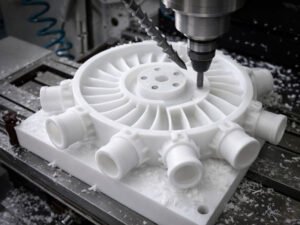

We specialize in HTV (High-Temperature Vulcanized) silicone injection molding to create flexible, durable parts for diverse industries. Unlike LSR, HTV silicone starts as a solid material and is molded under high heat and pressure, producing strong and resilient components.

Our process begins with precision mold design and uses advanced equipment to inject solid silicone into heated molds. After molding, parts are cured and finished to achieve tight tolerances and excellent surface quality—ideal for both prototypes and high-volume production with reliable, cost-effective results.

| Parameter | Recommended Range |

|---|---|

| Wall Thickness | 1.0mm – 5.0mm |

| Maximum Part Size | 300mm × 300mm |

| Minimum Feature Size | 0.5mm – 1mm |

| Tolerances | ±0.1mm – ±0.25mm |

Silicone Material Properties

Silicone rubber is a flexible, chemically stable elastomer ideal for molded parts requiring high performance under extreme conditions. In our production, we use HTV silicone material, which is solid before molding and offers excellent strength and heat resistance after curing.

| Property | Density | Tensile Strength | Flexural Strength | Impact Strength (Unnotched) | Heat Deflection Temp (0.45 MPa) |

|---|---|---|---|---|---|

| Value/Description | 1.02-1.05g/cm³ | 40 -50 MPa | 60-70 MPa | 20 -30 kJ/m² | 90-100℃ |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Related Process

Looking for High-Quality Silicone Injection Molding?

Advantages & Disadvantages of Silicone Injection Molding

Advantages

- Wide operating temperature range

- Excellent flexibility and resilience

- Biocompatible and skin-safe

- Stable under UV and weather exposure

- Customizable hardness and color

Disadvantages

- Higher material cost vs. thermoplastics

- Requires precise mold temperature control

- Not suitable for sharp edges or extremely thin walls

- Lower mechanical strength compared to some engineering plastics

Applications of Injection Molded Silicone

Automotive Industry

- Seals and gaskets

- Protective boots and sleeves

- Vibration dampening pads

Medical and Healthcare

- Mask components

- Valves and connectors

- Skincare applicators

Electronics

- Keypad buttons

- Cable boots

- Heat insulation components

Consumer Goods

- Kitchenware (bakeware, spatulas)

- Baby products (pacifiers, teething rings)

- Personal care items

Jiangzhi Silicone Molding Parts are Guaranteed

Cracks often come from stress during cooling, poor mold design, or even using the wrong processing temps. We focus on balanced part design and proper molding conditions to keep your ABS parts crack-free.