Custom Silicone Parts

Click to View

Custom Silicone Products We Manufactured

Jiangzhi creates high-quality custom silicone parts that fully meet the needs of modern industries. We offer complete customization of every part, including shape, size, hardness, color, logo, and packaging, ensuring optimal performance and compliance with strict standards.

How to Work With Us?

Custom Silicone Part Manufacturing Processes

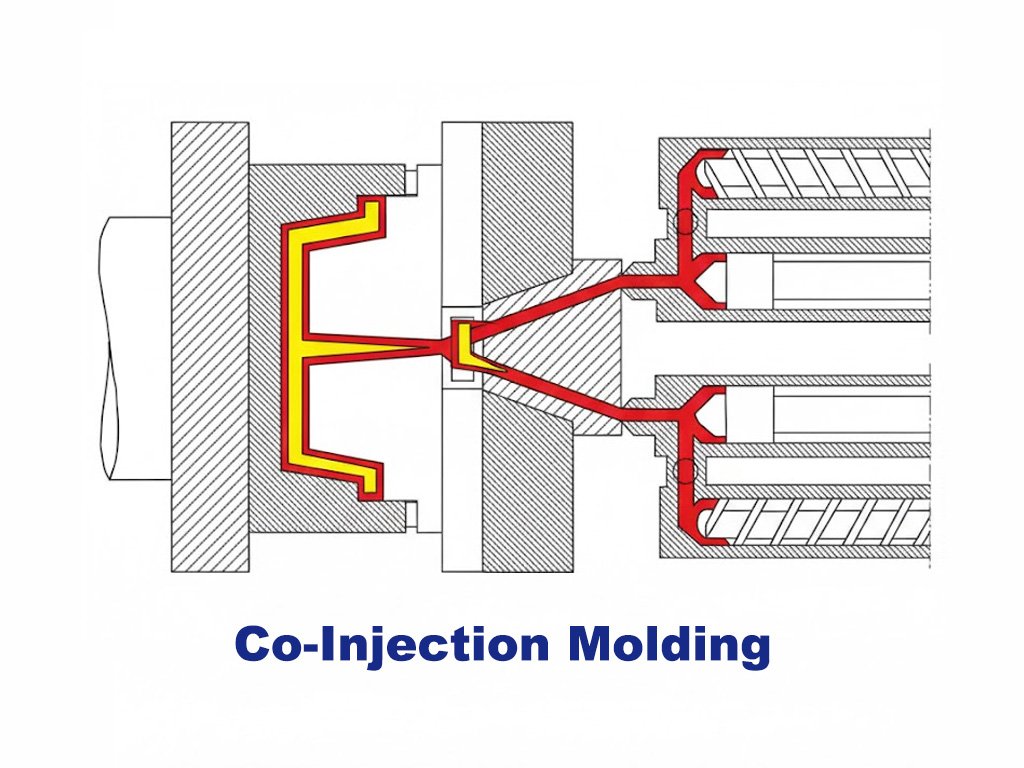

Silicone Injection Molding

Silicone injection molding uses high-temperature vulcanized rubber (HTV), which is preformed and injected into a heated mold. It is commonly used to produce silicone seals, gaskets, keypads, grommets, and bushings.

Advantages:

- Excellent for complex geometries

- Consistent quality for large-scale production

- Smooth finish with fine details

Limitations:

- Less flexible for very small batches

- Initial setup cost can be higher

View more details about silicone injection molding.

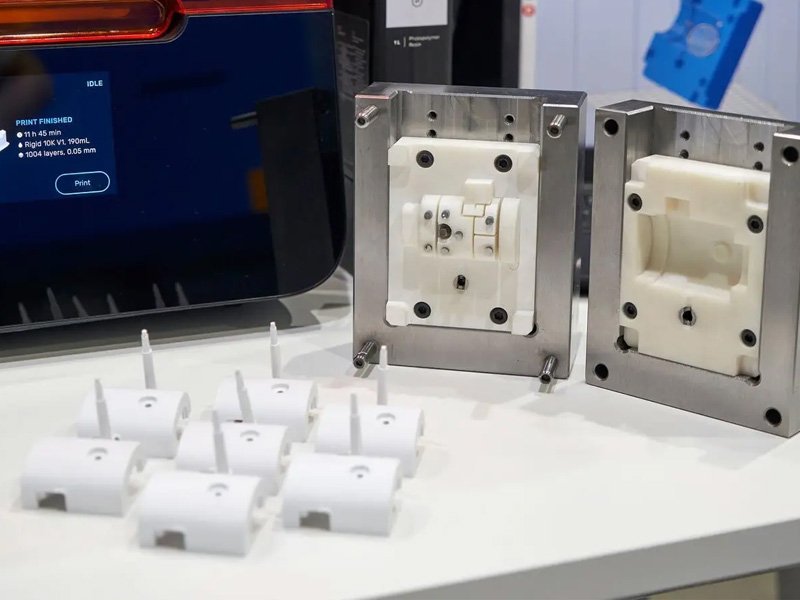

Silicone Compression molding

Silicone material is molded under heat and pressure, curing into flexible, durable parts with accurate dimensions. Perfect for custom silicone prototypes and small runs like seals, gaskets, keypads, and protective covers.

Advantages:

- Cost-effective for small batches and prototypes

- Can produce large or thick parts

- Efficient material usage with minimal waste

Limitations:

- Surface finish and precision are lower than injection parts

- Less suitable for highly intricate designs

View more details about silicone compression molding.

Injection or Compression? Find Your Custom Silicone Solution

Choose the silicone manufacturing method that suits your product’s complexity, batch size, and surface finish.

- Silicone injection molded parts are typically used for components with complex shapes, thin walls, or detailed features, and for medium to large production runs requiring consistent precision and repeatability.

- Compression molded parts are generally chosen for larger, thicker, or simpler shapes, and for small to medium production runs where mold complexity is lower and tight tolerances are not required.

Start Your Custom Silicone Parts Project!

How to Choose the Right Silicone Parts Manufacturer?

Selecting the right custom silicone parts manufacturer means finding a partner who delivers precision, durability, and reliability.

At Jiangzhi, we have over 40 years of experience and more than 10,000 successful custom projects in medical, automotive, food, and electronics applications. Our team works closely with clients to customize every aspect of silicone parts using advanced injection and compression molding technologies, supporting both small-batch prototypes and large-scale production, including OEM and private-label solutions. With rigorous quality inspections and complete process oversight, Jiangzhi ensures each custom silicone part meets your unique application needs.