Injection Molding Packaging

Click to View

Injection Molding Solutions for Packaging Components

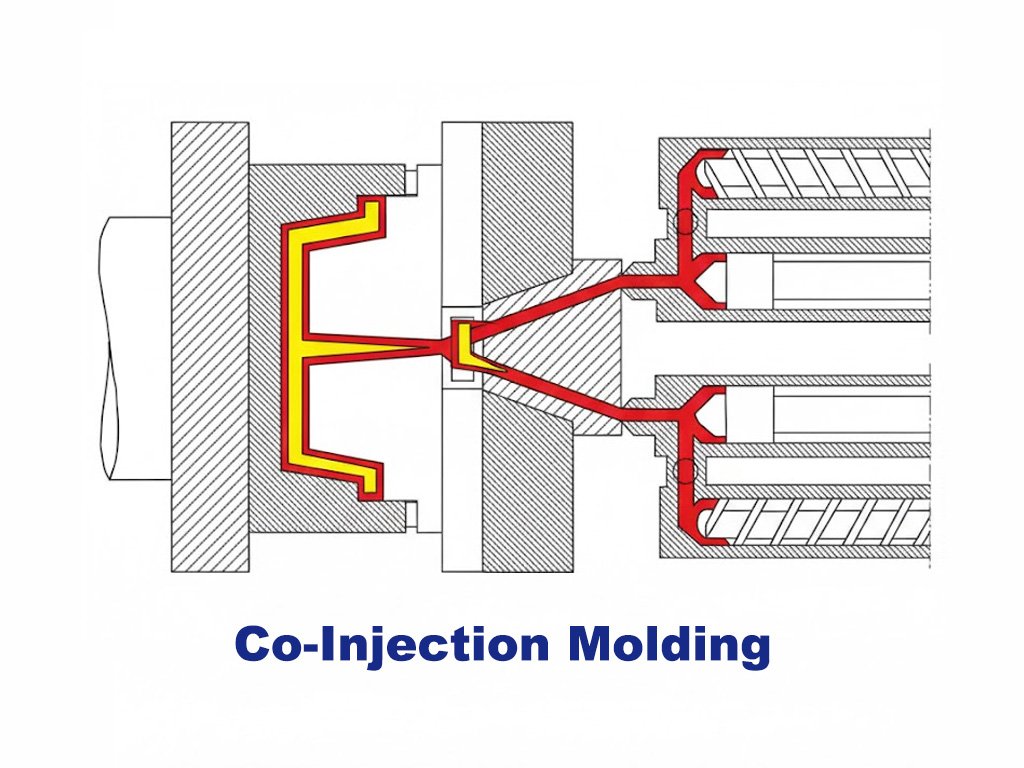

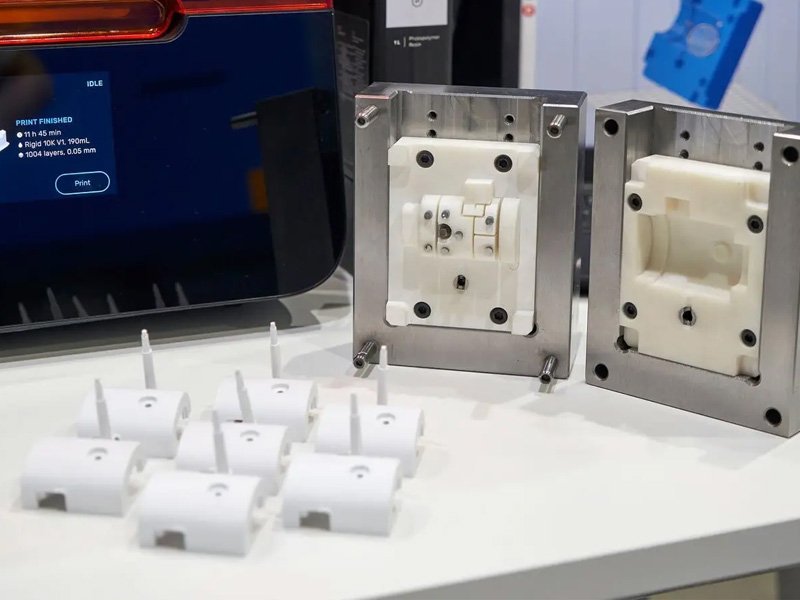

Injection molded packaging uses the injection molding process, in which thermoplastic pellets are heated and melted, then injected into a metal mold cavity under high pressure, cooled, and solidified to form the desired packaging components. This process is ideal for producing rigid or semi-rigid plastic packaging parts with high precision, complex structures, and dimensional stability, meeting diverse requirements for functionality, appearance, and performance in packaging design.

Jiangzhi provides professional injection molding solutions for the packaging industry, covering the entire process from mold design and material selection to precision injection molding and post-processing. With advanced production lines and automation technology, we help clients in food, cosmetics, medical, electronics, and industrial sectors create high-quality, customized packaging components efficiently and cost-effectively.

Get Your Custom Injection Molding Packaging Quote!

Find the Right Material for Your Packaging

Plastic is the leading choice for packaging thanks to its versatility and cost-effectiveness. For added strength or premium appeal, combining plastic with metal coatings is also possible with Jiangzhi, creating durable and attractive solutions.

- ABS

- PC

- PP

- POM

- PE

- PS

- PVC

- PTFE

- PA

- PMMA

- UHMWPE

Injection Molding Applications in Consumer Electronics Packaging

Injection molding delivers the precision and protection essential for consumer electronics packaging. Our solutions leverage tight tolerances and versatile materials to manage both security in the supply chain and aesthetics at retail. We provide manufacturers with cost-effective components. Key Consumer Electronics Packaging includes:

- Protective Trays: smartphone trays, laptop component trays, PCB holder trays.

- Accessory Storage Boxes: earphone boxes, USB accessory cases, cable organizers.

- Transparent Display Cases: transparent phone covers, tablet display cases, accessory showcase boxes.

- Small Rigid Protective Shells: power bank shells, portable hard drive cases, compact speaker enclosures.

Injection Molding Applications in Automotive Packaging

Our solutions offer robust, reusable packaging designed to withstand the rigors of the supply chain, while ensuring precise component alignment and shock absorption for sensitive parts. This capability is key to minimizing damage, reducing overall part weight, and streamlining assembly line feeding. Typical examples include:

- Protective Trays: headlight module trays, dashboard assembly trays, and electronic control unit (ECU) trays.

- Accessory Storage Boxes: Screw & Fastener Organizers, sensor component boxes, and small trim parts.

- Shock-Absorbing Inserts: headlamp inserts, sensor cushioning pads, control module protective inserts.

- Exterior & Interior Component Packaging: tail light housings, grille covers, center console parts.

Custom Injection Molded Packaging Solutions by Jiangzhi

In today’s competitive market, packaging failure is not an option. Jiangzhi specializes in eliminating packaging risk. We deliver custom injection molding packaging solutions that guarantee precision, protection, and operational efficiency across your supply chain. Partner with us to achieve double-digit cost optimization through material efficiency and rapid turnaround, ensuring your product is delivered intact, on time, and presented to the highest market standard.