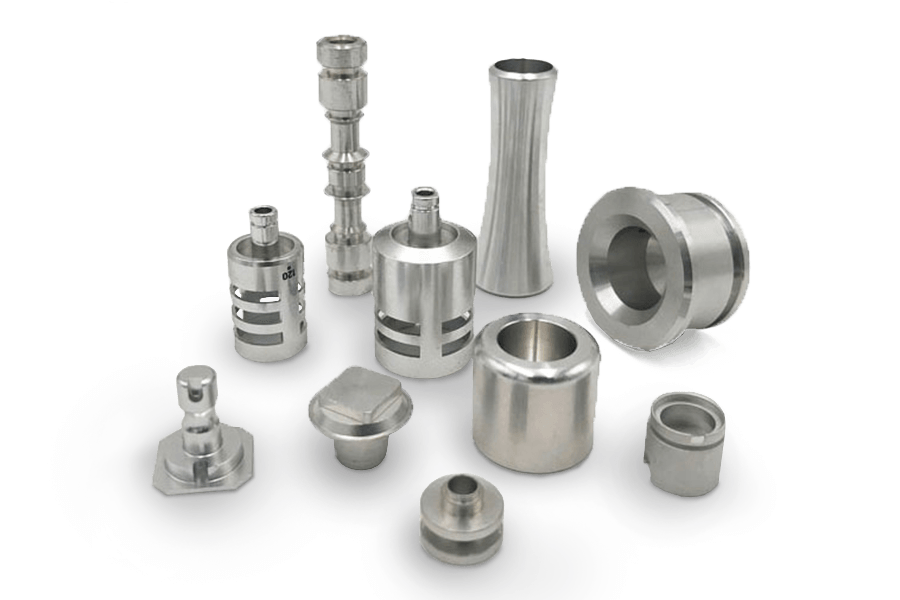

CNC Metal Machining Parts

From prototype to low-volume or high-volume customization, delivering precision CNC metal parts tailored to your needs.

- Precision machining with tight tolerances

- Wide range of metal materials available

- Fast turnaround and reliable delivery

- Custom finishes to meet your needs

Machined metal parts are made by removing material from solid raw blocks using CNC turning and milling machines. This process uses various cutting tools and techniques, like turning and milling, to create precise shapes and features. Today, CNC machines deliver high precision, repeatability, and efficiency, helping them become widely used in metal parts manufacturing.

At Jiangzhi, we provide tailored CNC milling and turning services for everything from rapid prototyping to high-volume production. We work with various metal machining parts and offer finishing options like anodizing, plating, polishing, and heat treatment. Upload your design files and requirements to get a quick quote, lead time, and manufacturability feedback.

CNC Metal Parts Materials

Aluminum

Stainless Steel

Carbon Steel

Alloy Steel

Brass

Copper

Metal CNC Machined Parts Surface Treatment Options

To improve the appearance and performance of your CNC-machined metal components, we offer a variety of surface finishing services. Whether you need a clean matte surface, enhanced aesthetics, or clear part labeling, our finishing options ensure that to meet your metal machining parts.

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Machining Metal Parts Case Show

Advantages of Metal Machining Parts

- High precision with tight tolerances

- Works with various metals like aluminum and stainless steel

- Consistent quality for prototypes and production

- Fast turnaround without costly tooling

- Supports custom surface finishes

Why Choose Jianzhi as Your CNC Metal Parts Supplier?