Rapid Prototyping Services for Faster Product Development

- Injection Molding Prototyping

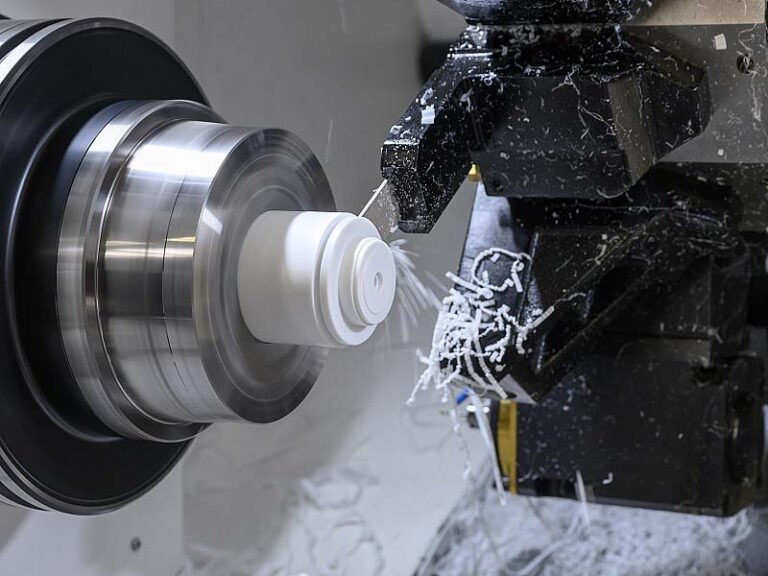

- CNC Rapid Prototyping

- Low Volume Production

- Fast & Low-Cost Solutions

What is Rapid Prototyping?

Rapid prototyping (Fast Prototyping) is a product development method that quickly turns new design concepts into physical samples or parts. It serves as a critical step before full-scale production, helping to verify a product’s appearance, feel, and functionality.- Multiple design versions can be produced at once, or existing prototypes can be quickly revised.

- Prototypes are ideal for functional testing, design approval, iterative optimization, crowdfunding presentations, or trade show models.

- Early detection and correction of design issues reduces risks in mass production and saves overall development costs.

Rapid Prototyping Manufacturing Capability

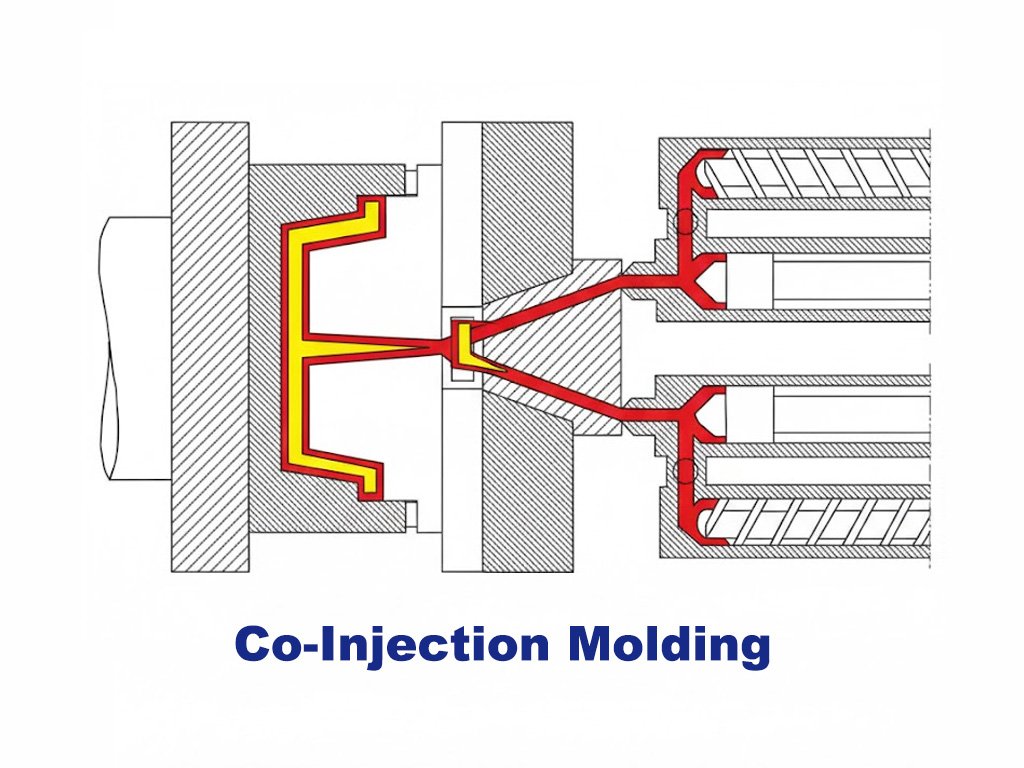

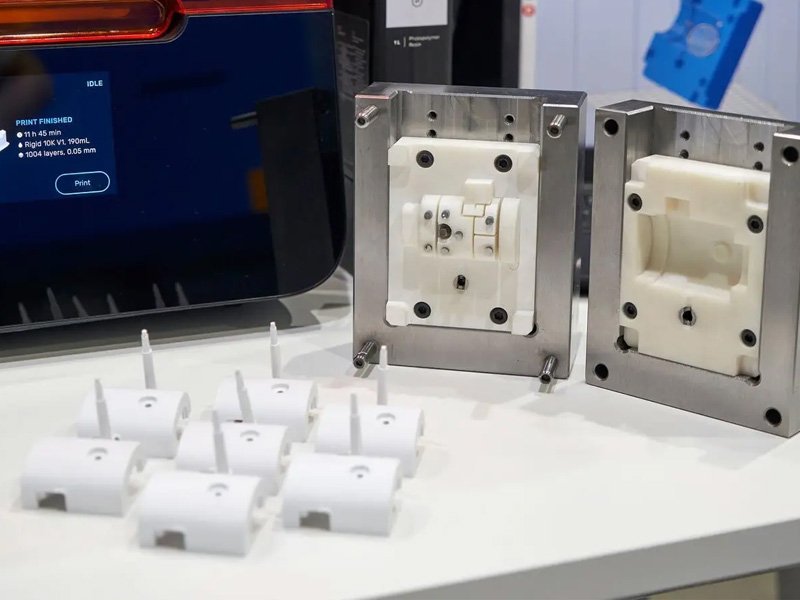

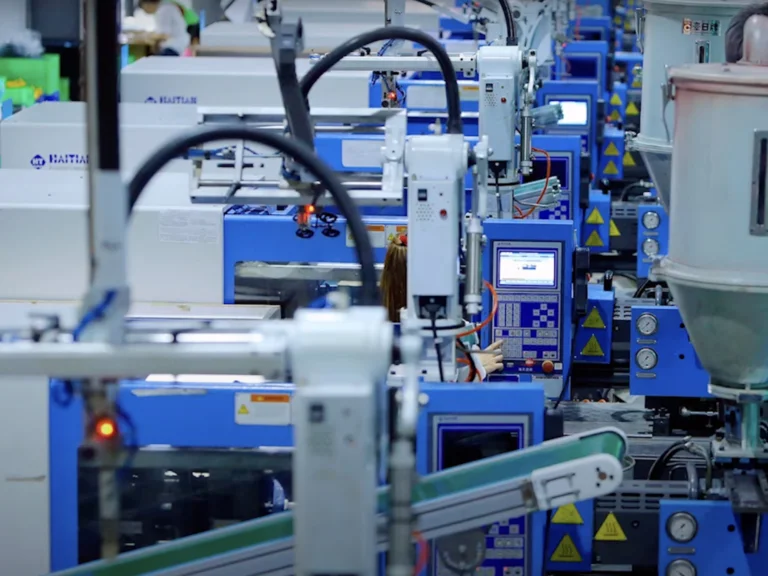

Injection Molding Service

At Jiangzhi, rapid injection molding makes durable plastic prototypes and small production runs. It supports functional testing, high-fidelity evaluation, and temporary production with 2–3 week lead times for fast design validation.

Rapid injection molding meets strict material and mechanical requirements that additive manufacturing cannot, providing high repeatability and multiple near-final parts for thorough testing.CNC Rapid Prototyping

Jiangzhi’s CNC rapid prototyping produces precise plastic or metal parts with tight tolerances, smooth surfaces, and high hardness for functional testing and design validation.

Our CNC machines, including milling, lathes, and EDM, cover all prototyping needs. Post-processing like spray painting, silk screen printing, or electroplating provides the desired finish and appearance.

Materials for Rapid Prototyping at Jiangzhi

Plastic Prototypes

We work with various plastics to create fast, cost-effective prototypes for consumer electronics, automotive, and engineering parts. Such as:

- ABS

- PC

- Nylon

- PP

- POM

- PMMA

Metal Prototypes

Our metal material options ensuring durability, precision, and near-final performance for testing. Including:

- Aluminum

- Stainless Steel

- Alloy

- Copper

- Brass

Custom Rapid Prototypes Parts Surface Finishes

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Why Choose Rapid Prototyping?

Jiangzhi’s rapid prototyping services provide high-precision, production-ready prototypes with fast turnaround times. Key advantages include:

- Precision & Accuracy – Prototypes are manufactured to strict dimensional and tolerance standards for reliable testing.

- Material Versatility – We work with plastics, metals (aluminum, steel, titanium), and other materials to meet specific design requirements.

- Speed & Efficiency – Quickly produce multiple prototypes to accelerate development and shorten time-to-market.

- Design Iteration – Create multiple versions for testing and refining designs, ensuring optimal final products.

- Complex Geometries – Capable of producing intricate parts for industries like automotive, aerospace, and medical.

To Start Rapid Prototyping, You Need to Consider...

- Will the prototype serve mainly as a visual model or a functional model?

- What is my budget for prototype development?

- Does the part involve multiple components or interconnected features?

- What level of surface finish and clarity is required?

- What materials should the prototype be made from?

- How important are strength and durability for the intended use?

- How closely should the prototype resemble the final production version?