Aluminum CNC machining is a cornerstone of modern manufacturing, enabling high-precision, complex parts across industries such as aerospace, automotive, electronics, and medical devices. Aluminum’s unique combination of lightweight, strength, and machinability makes it ideal for CNC machining. This guide explores the aluminum CNC process, material selection, advantages, challenges, and applications.

What Is Aluminum CNC Machining?

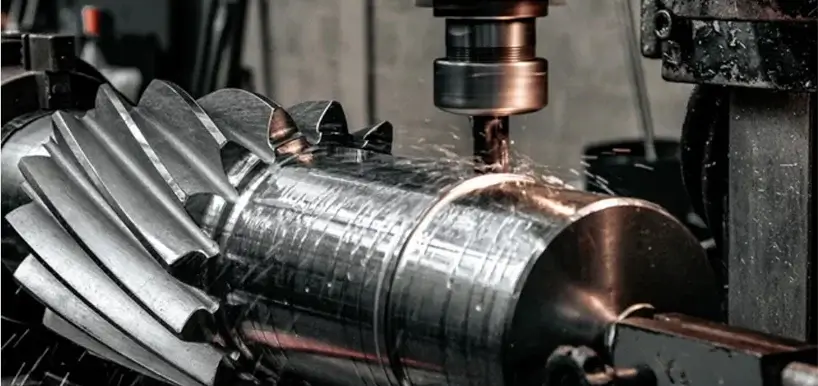

Aluminum CNC machining involves shaping and cutting aluminum alloys using computer numerical control (CNC) machines. Popular techniques include:

- CNC Milling: Uses rotary cutting tools along multiple axes to create slots, pockets, and contoured surfaces.

- CNC Turning: Shapes cylindrical parts like shafts and bushings by rotating the workpiece against stationary tools.

- CNC Drilling: Produces precise holes for fasteners, assemblies, or fluid passages.

- Laser Cutting & Waterjet Cutting: Ideal for large or heat-sensitive aluminum parts, preserving structural integrity.

CNC systems convert CAD designs into CAM programs, ensuring efficient, repeatable, and precise machining cycles.

Aluminum Materials for CNC Machining

Choosing the right aluminum alloy is key to balancing machinability, strength, corrosion resistance, and cost. Common alloys include:

| Types | Tensile Strength (MPa) | Corrosion Resistance | Machinability | Common Applications |

|---|---|---|---|---|

| 6061 | ~310 | Excellent | High | Automotive, Construction |

| 7075 | ~570 | Moderate | Moderate | Aerospace |

| 2024 | ~470 | Poor | Moderate | Aerospace |

| 5052 | ~210 | Excellent | High | Marine |

| 5083 | ~315 | Excellent | High | Marine |

| MIC-6 | ~165 | Good | Excellent | Precision Tooling |

Selection Tips:

- 6061: Versatile, easy to machine, good corrosion resistance.

- 7075: Very strong, more challenging to machine, for aerospace/high-stress parts.

- 2024: High fatigue resistance, suitable for aircraft structures.

- 5052/5083: Excellent corrosion resistance, ideal for marine applications.

- 2011 & MIC-6: Highly machinable, precision tooling, or flat fixtures.

CNC Machining Processes and Characteristics

Aluminium CNC machining encompasses several processes, each tailored to specific part geometries and requirements. The primary methods include:

CNC Milling Machining

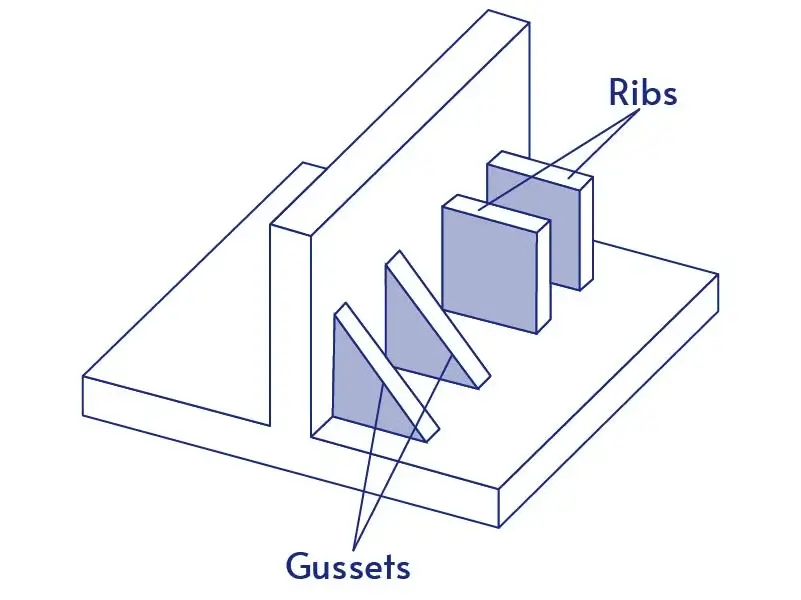

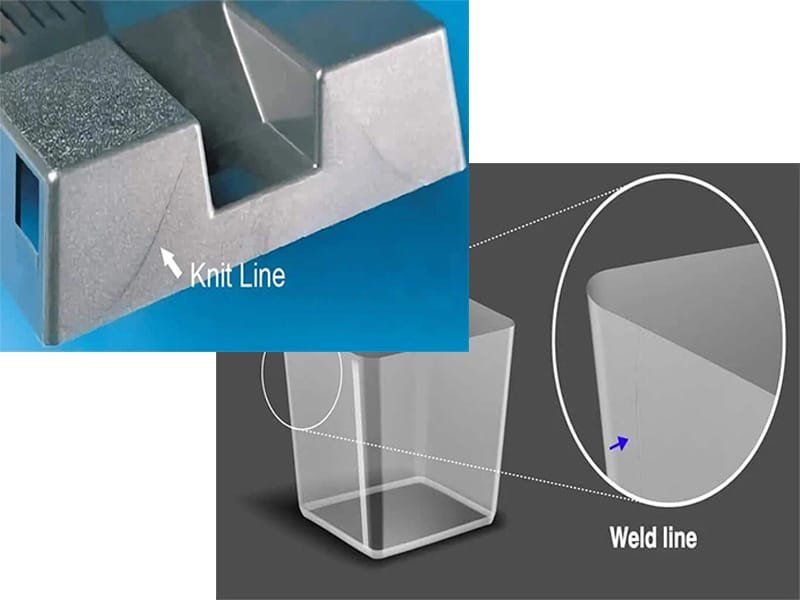

Milling is the popular of CNC milling aluminum, using rotating cutting tools to remove material from a stationary aluminum workpiece. An aluminum mill operates with multi-axis CNC machines (e.g., 3-axis or 5-axis), allowing intricate toolpaths programmed via CAM software. Aluminum’s softness enables high-speed milling, achieving tight tolerances (±0.01 mm) and smooth finishes. However, care must be taken to manage heat, as aluminum’s low melting point can cause deformation if not properly cooled. The process excels at creating complex shapes, such as slots, pockets, and contoured surfaces, making it ideal for parts like aerospace brackets or electronic enclosures.

CNC Turning Machining

In aluminum machining, turning involves rotating the aluminum workpiece while a stationary cutting tool shapes it. Aluminum’s machinability allows faster spindle speeds compared to steel, but long, stringy chips can form, requiring chip breakers or through-spindle coolant to maintain efficiency. This process is perfect for cylindrical components, such as shafts, bushings, or fittings used in automotive or aerospace applications.

CNC Drilling Machining

Drilling in aluminum for CNC creates precise holes for fasteners, assemblies, or fluid passages, often as a secondary operation after milling or turning. CNC machines use specialized drill bits to achieve accurate hole depths and diameters. Aluminum’s softness makes drilling efficient, but its tendency to form gummy chips can clog tools. This process is vital for applications requiring secure fastening or lightweight assemblies.

Waterjet Cutting

Waterjet cutting has the ability to slice thick aluminum plates without generating heat, avoiding thermal distortion. A high-pressure stream of water cuts through the material with precision, ideal for large or heat-sensitive parts like marine fittings. Unlike milling or turning, waterjet cutting doesn’t rely on rotating tools, making it versatile for irregular shapes. Its downside is slower cutting speeds for intricate designs, but it excels in preserving aluminum’s structural integrity, especially for alloys like 5052 or 5083.

Advantages and Challenges of Aluminum CNC Machining

Aluminum CNC machining offers an array of benefits, but it also presents challenges that require careful management. Below, we explore the key advantages of CNC aluminum and the hurdles that come with it.

Advantages of Aluminum CNC Machining

Strength-to-Weight Ratio: Aluminum’s density is about one-third that of steel, making it remarkably lightweight. Despite this, alloys like 7075 deliver tensile strengths up to 570 MPa, rivaling heavier metals. This high strength-to-weight ratio makes CNC milling aluminum ideal for weight-sensitive applications, where reducing mass without sacrificing durability is critical.

Machinability: Aluminum alloys are soft and easy to cut, requiring less power and causing minimal wear on machine tools compared to metals like titanium or steel. This machinability allows aluminum mills to operate at high speeds, reducing machining time and costs.

Corrosion Resistance: Aluminum forms a protective oxide layer when exposed to air, offering excellent resistance to corrosion in various atmospheric conditions. Anodizing can further enhance this property for alloys with moderate resistance. This durability extends the lifespan of CNC aluminum parts.

Custom Finishing: Aluminum for CNC supports a wide range of surface finishes, including anodizing, chromate conversion coating, powder coating, and painting. These finishes enhance corrosion resistance, improve aesthetics, or meet specific functional requirements.

Electrical Conductivity: Aluminum alloys provide electrical conductivity for their parts, making them applicable for electrical components.

Recyclability: As a subtractive process, aluminum CNC machining generates significant chip waste, but aluminum’s recyclability makes it an ideal material.

Common Aluminum CNC Machining Challenges & Solutions

Tool Wear from Oxide Layer: Aluminum’s natural oxide layer can accelerate tool wear during high-speed CNC milling. To address this, use carbide or diamond-coated tools (e.g., TiB2, ZrN) to maintain cutting efficiency and extend tool life.

Vibration and Chatter: The softness of aluminum may cause vibrations or chatter, affecting surface finish. Optimizing feed rates (0.05–0.15 mm/rev for finishing) and using vibration-damping tool holders can stabilize the process.

Thermal Deformation: Aluminum’s low melting point (~660°C) can lead to thermal deformation during intensive machining. Applying coolants, such as soluble-oil emulsions or through-spindle coolant systems, helps dissipate heat and preserve dimensional accuracy.

Chip Management: Aluminum produces long, stringy chips that can clog machines and disrupt operations. Using chip breakers or high-pressure coolant systems facilitates chip evacuation, ensuring smooth and efficient machining.

Applications of Aluminum CNC Machining

Because of its favorable properties and machining versatility, aluminum CNC machining serves multiple industries:

- Aerospace: High-strength structural components, brackets, and housings.

- Automotive: Engine parts, transmission components, chassis parts, and custom accessories.

- Electronics: Heat sinks, housings, and enclosures requiring precision and good thermal properties.

- Medical Devices: Surgical tools, implants, and diagnostic equipment components.

- Defense and Marine: Lightweight armor plates, precision mountings, and corrosion-resistant parts.

Future Trends and Technology Development

The future of aluminum CNC machining is evolving rapidly. AI and machine learning optimize toolpaths and predict tool wear, enhancing precision and efficiency. Automation, including robotic part handling, streamlines production and reduces costs. Advanced tool coatings, like diamond or TiB2, extend tool life, while sustainable practices leverage aluminum’s recyclability to minimize waste. Additionally, eco-friendly machining methods and advanced surface treatments will gain importance to meet environmental and performance demands.

Conclusion

Aluminum CNC machining service delivers lightweight, precise, and durable components, empowering industries like aerospace and automotive with versatile solutions. As technology advances, its efficiency and sustainability continue to redefine manufacturing. Contact Jiangzhi today to bring your aluminum machining project to life!