In manufacturing, casting vs machining are two common processes used to produce parts. Each offers specific benefits, limitations, and economic considerations. Selecting the appropriate process can reduce costs and improve efficiency.

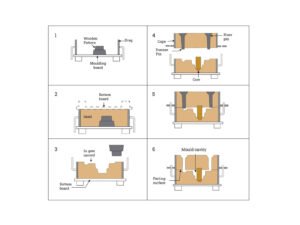

What is Casting?

Casting is a forming method where molten material, typically metal, is poured into a mold and allowed to solidify into the desired shape. This process is commonly used to produce medium- to large-sized components, especially when the part requires internal cavities, thick sections, or complex geometries. For example, engine blocks, agricultural equipment, pump housings, and general industrial applications.

Common Casting Types

Several types of casting exist, each suited to different applications and materials.

- Sand Casting: Used for large components with moderate tolerances. It is flexible in terms of size and material options.

- Die casting: Involves forcing molten metal material into a metal mold under high pressure. It is ideal for high-volume production of non-ferrous metals. Offers smoother surfaces and better dimensional control.

- Investment Casting: Provides better accuracy and surface quality than sand casting. It is suitable for intricate shapes and smaller components.

- Centrifugal casting: The mold rotates to distribute molten material evenly, producing cylindrical parts like pipes with uniform thickness.

Advantages and Disadvantages

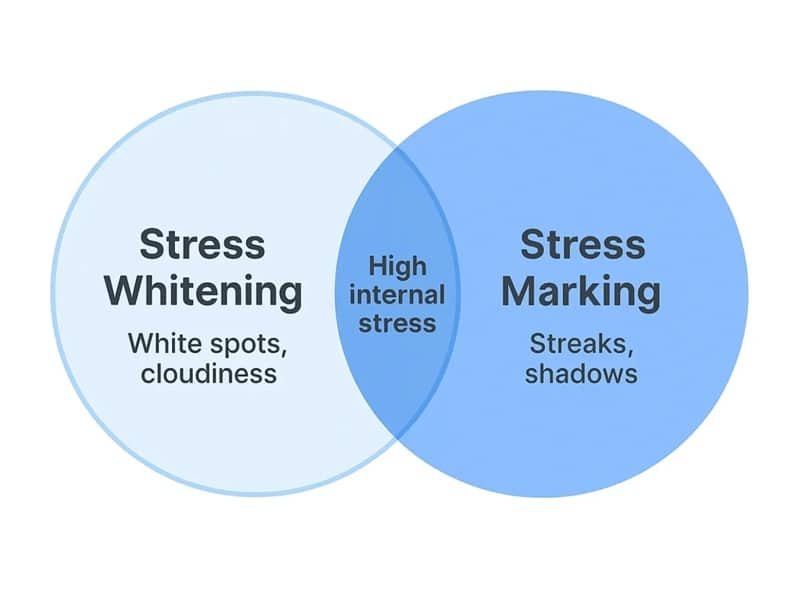

It allows for the production of complex shapes, including internal cavities or thick-wall cross-section designs, without additional assembly. The process is efficient for high-volume runs because the per-unit cost decreases as production increases. It offers a wide range of material options. However, casting has disadvantages. It can result in defects such as porosity or shrinkage, requiring additional inspection. Surface finish is often rough, necessitating secondary operations. Initial tooling costs for molds are high, making it less suitable for low volumes. Tolerances are typically looser, around ±0.1 mm, compared to other methods.

What Is Machining?

Machining is a subtractive manufacturing process in which a cutting tool removes material from a solid block or billet. Machining is commonly applied to prototypes, custom parts, functional metal components, aerospace fittings, medical equipment frames, mechanical housings, and applications requiring tight tolerances or fine surface finishes.

Common Machining Types

- CNC Milling: Removes material using rotating cutting tools, suitable for prismatic geometries, pockets, and complex 3D surfaces.

- CNC Turning: The workpiece rotates while the tooling removes material. It is ideal for round parts such as shafts, pins, and rings.

- Drilling and Tapping: Used for holes and threads, often required even when a part is initially produced through casting.

- Grinding: Employs abrasive wheels for fine surface finishes and tight tolerances. It is applied when extremely tight tolerances or very fine surface finishes are required.

Advantages and Disadvantages

Machining provides high precision and excellent surface finishes. It works with a wide range of materials, including metals, plastics, and composites. The process is flexible for low-volume production and allows quick changes in design. CNC machining adds efficiency through automation, reducing human error. On the downside, machining generates significant waste from removed material, increasing material costs. It is time-consuming for complex internal features and less economical for large quantities due to higher per-unit expenses. Tool wear requires maintenance, adding to operational costs.

Key Differences Between Casting vs Machining

Casting and machining differ in several aspects, influencing their selection in manufacturing.

Cost Differences

Casting involves upfront tooling costs for mold creation. Once the mold is produced, the cost per part decreases significantly for high-volume orders. Machining does not require tooling but has a higher per-unit cost due to material removal and machining time. Therefore, casting becomes more economical for medium to high volumes, while machining is cost-effective for prototypes and low-volume runs.

Production Speed

Production speed varies by scale. Machining offers a shorter initial lead time since no molds are needed. Parts can be produced immediately once the program is ready. Casting requires mold fabrication before production can start, which may extend delivery schedules. However, once the mold is finalized, casting achieves faster throughput for large batches.

Precision and Tolerance

Machining achieves tight tolerances with smooth surfaces. Casting provides looser tolerances, and parts may need post-processing like machining to refine accuracy. This makes machining preferable for components requiring exact fits.

Material Suitability

Casting is limited to materials that can be melted and poured, such as alloys of iron, aluminum, and copper. It alters material properties through heating and cooling. Machining handles nearly any solid material, preserving original properties without melting. CNC machining extends this to advanced composites and hard metals.

Capability for Complex Geometries

Casting easily produces components with complex internal cavities, thick sections, and shapes that would be cumbersome or impossible to machine. On the other hand, machining excels at external details and precise features but becomes less efficient as geometry becomes intricate.

Factors to Consider When Choosing Between Casting and Machining

Selecting between casting vs machining requires examining several project-specific factors.

Production Volume

Low-volume and prototype parts typically favor machining due to the minimal mold cost. High-volume demand supports casting because tooling investment is amortized across larger quantities.

Part Complexity

Parts with internal passages, thick-walled structures, or challenging shapes lean toward casting. Precision components with tight tolerances or detailed surfaces favor machining or a hybrid approach.

Tolerance Requirements

Applications needing high accuracy, like aerospace fittings, lean toward machining. Less critical tolerances, as in structural components, allow casting with optional finishing.

Material Selection

If the material must retain specific properties without heat effects, machining is better. For meltable metals where property changes are acceptable, casting works.

Lead Time and Budget

Machining offers shorter lead times for small orders, fitting tight schedules. Casting’s longer setup may extend timelines, but it reduces costs in bulk. Budget evaluation includes total ownership costs, encompassing tooling, materials, and secondary processes.

Conclusion

In many cases, casting vs machining is not a strict either-or choice; both processes may be combined to balance cost and performance. Jiangzhi offers professional process analysis and customized manufacturing solutions to help you achieve the best balance among cost, precision, and overall performance, ensuring your components meet both functional and economic goals.

FAQ

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.