In modern manufacturing, polycarbonate (PC) stands out as a highly versatile and robust thermoplastic. This guide dives into the essentials of CNC polycarbonate machining, exploring its processes, methods, design strategies, and applications to help you achieve optimal outcomes.

What Is Polycarbonate?

Polycarbonate (PC) is a transparent, impact-resistant thermoplastic renowned for its durability and versatility. With an impact strength of 600-850 J/m, it outperforms many materials. Its optical clarity rivals glass, while its heat resistance (up to 120°C) and lightweight nature make it ideal for demanding applications.

Compared to ABS, PMMA, and POM, PC offers superior toughness and clarity but requires careful machining due to its sensitivity to heat and stress.

Why Choose CNC Machining for Polycarbonate?

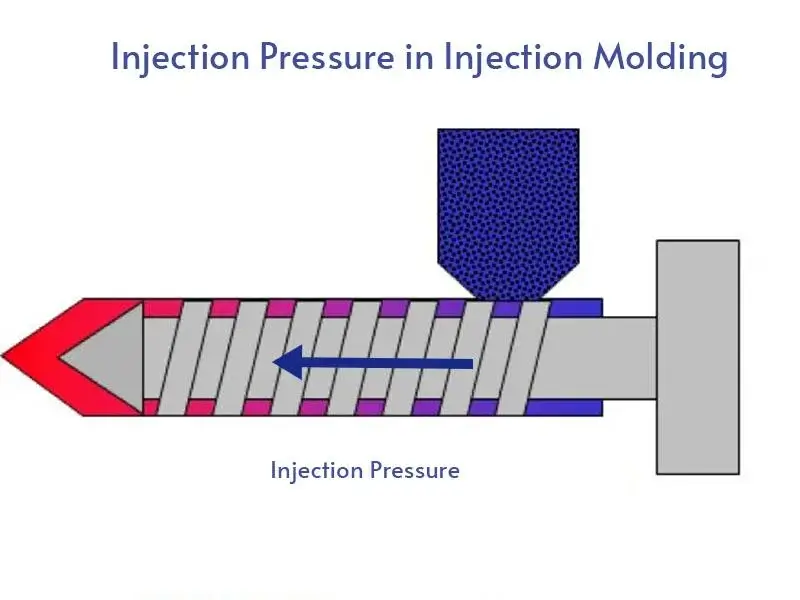

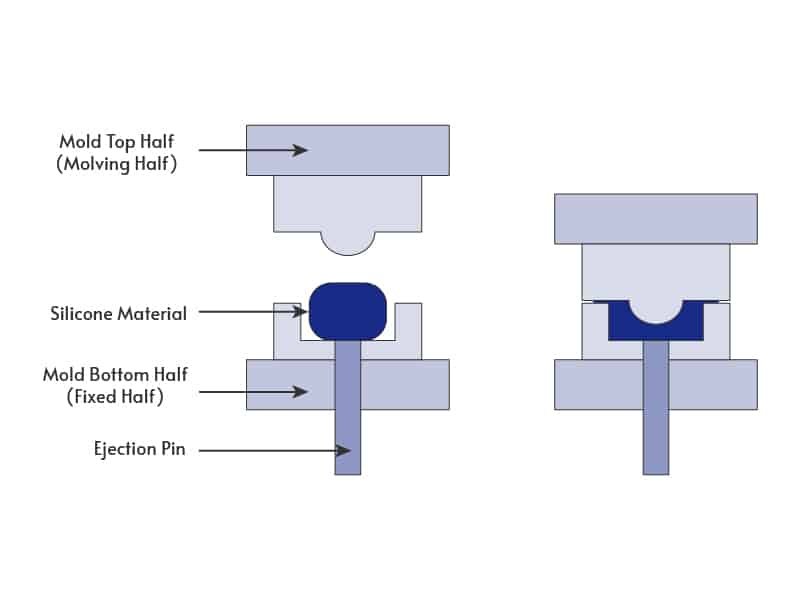

CNC machining polycarbonate offers precision that other methods, like injection molding or 3D printing, struggle to match. Computer Numerical Control (CNC) systems enable tight tolerances (±0.01 mm), making them ideal for complex geometries and low- to medium-volume production. Unlike injection molding, which requires expensive molds, CNC polycarbonate machining is cost-effective for prototypes and custom parts. Its versatility supports intricate designs without sacrificing material integrity, a critical factor for industries like aerospace and medical.

Moreover, CNC machining allows for rapid iteration. Designers can test prototypes, refine designs, and produce final parts without lengthy setup times. For polycarbonate, which can be sensitive to heat and stress, CNC machining provides the control needed to avoid defects like cracking or melting.

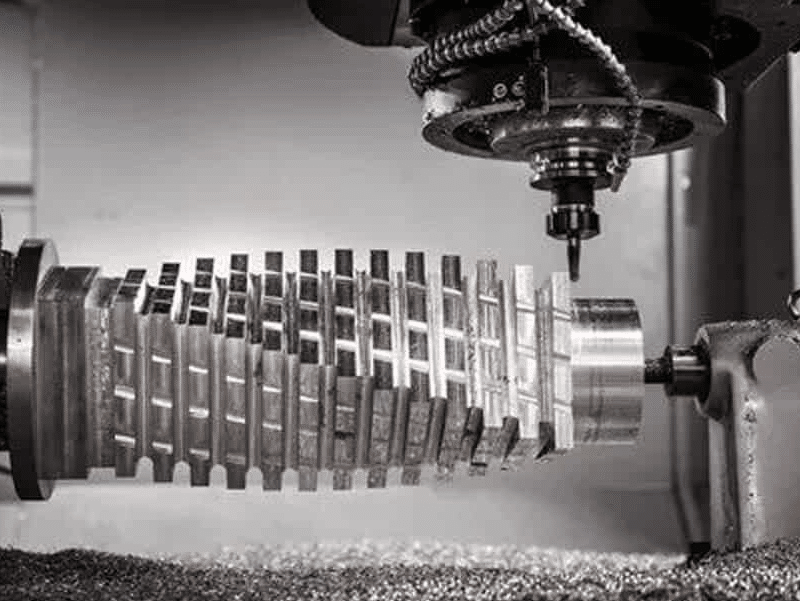

How Does CNC Polycarbonate Machining Work?

CNC machining polycarbonate is a subtractive manufacturing process where a computer-controlled cutting tool removes material from a polycarbonate block or sheet to achieve the desired shape. The workflow includes:

- Design and CAD Modelling: Parts are first designed using CAD software, ensuring optimized geometry for machining.

- Material Selection: Picking the right polycarbonate grade depending on heat resistance, clarity, or strength needs.

- Machine Setup: The CNC machine is programmed with tool paths derived from CAM software.

- Workpiece Fixturing: The polycarbonate is securely clamped to minimize vibration that might cause inaccuracies or surface defects.

- Machining Operations: Utilizing CNC milling, drilling, turning, or other techniques, the machine gradually removes material while controlling speed and coolant application.

- Surface Finishing: Post-machining surface treatments like vapor polishing or mechanical buffing enhance aesthetics and functionality.

- Quality Inspection: Dimensional checks ensure the final part meets the specifications and tolerances.

Common Polycarbonate Machining Methods

CNC machining polycarbonate encompasses several techniques, each suited to specific part requirements. Here’s an overview:

CNC Milling

The most versatile and widely used method involves rotating cutting tools that shape the material by removing chips. Most CNC mills use carbide or high-speed steel cutters paired with water-soluble, non-aromatic coolants to prevent melting. Multiple light passes optimize dimensional stability and prevent stress cracking.

CNC Drilling

Precision drilling with sharp bits and controlled feed rates creates clean holes without chipping. Slow spindle speeds and peck drilling (incremental depth cuts) minimize heat buildup.

CNC Turning

Using lathes to machine cylindrical parts, turning requires well-maintained, sharp tools and cooling strategies to avoid surface defects and thermal distortion.

Laser Cutting

Best for thin sheets, laser cutting gives extremely precise edges, but must avoid overheating that causes melting or yellowing.

Waterjet Cutting

A non-thermal method using high-pressure water mixed with abrasives to cut thick sheets without introducing heat stress, ensuring clean and accurate edges.

CNC Routing and Engraving

These methods are used for more intricate 2D or shallow 3D contours, employing single-flute sharp bits for chip evacuation and fine finishes. Low-power settings and shallow depths prevent burning or distortion.

Surface Finishing and Post-Processing Options

Surface finishing enhances the aesthetics and functionality of CNC-machined polycarbonate parts. Common options include:

Polishing: Achieves optical clarity, ideal for lenses or transparent covers. Manual or vapor polishing smooths surfaces but requires care to avoid micro-scratches.

Sandblasting: Creates a matte or frosted finish, reducing glare for displays or panels.

Coating: Applies protective layers (e.g., UV-resistant coatings) to enhance durability or scratch resistance.

Flame Polishing: Uses controlled heat to smooth edges, though it risks thermal stress if overdone.

Design Tips for Polycarbonate CNC Machining

Effective design ensures successful CNC machining polycarbonate. Follow these tips:

- Rounded Corners: Use a minimum radius of 1 mm to reduce stress concentrations, which can lead to cracking.

- Uniform Wall Thickness: Maintain 1-3 mm thickness to prevent warping or uneven cooling during machining.

- Avoid Sharp Internal Corners: Opt for larger tool diameters (e.g., 3 mm or more) to simplify machining and reduce stress.

- Minimize Deep Cuts: Use multiple passes when machining thicker sections to reduce heat buildup.

- Use Proper Clamping: Secure but not overly tight clamping avoids deformation and vibration.

- Account for Thermal Expansion: Polycarbonate’s coefficient of thermal expansion (65-70 × 10⁻⁶/°C) requires loose tolerances for parts exposed to temperature changes.

- Prototype Testing: Test designs on scrap material to verify machinability and fit before full production.

- Toolpath Optimization: Design toolpaths to minimize tool changes and reduce machining time, lowering costs.

Applications of CNC Machining Polycarbonate

Polycarbonate parts made via CNC machining serve diverse industries:

Automotive: Headlight lenses, interior dashboards, and protective panels.

Aerospace: Transparent canopies, instrument covers.

Medical Devices: Sterilizable housings, fluid reservoirs, and protective visors.

Electronics: Enclosures offering electrical insulation and impact resistance.

Construction: Skylights, safety barriers requiring durability and clarity.

Consumer Goods: Eyewear, display cases, and protective gear.

Tips to Achieve the Best Results in CNC Polycarbonate Machining

To maximize the quality of CNC machining polycarbonate, follow these practical tips:

- Use Sharp Tools: Polished carbide tools reduce friction and prevent material buildup, ensuring clean cuts.

- Optimize Cutting Parameters: Set low cutting speeds (100-300 m/min) and high feed rates (0.1-0.3 mm/rev) to minimize heat generation.

- Effective Cooling: Use mist cooling or compressed air instead of liquid coolants, which can interact with polycarbonate and cause stress cracking.

- Good Chip Removal: Vacuum or compressed air prevents chip accumulation that can scratch or jam.

- Consider Annealing: Post-machining heat treatment reduces internal stresses and prevents cracking.

- Secure Fixturing: Clamp workpieces firmly to avoid vibrations, which can lead to cracks or imprecise cuts.

- Maintain Stable Environment: Temperature and humidity control minimize material distortion during and after machining.

- Test Parameters: Run trials on scrap polycarbonate to fine-tune settings before machining final parts.

- Inspect Regularly: Check tools for wear and parts for defects like micro-cracks or surface burns during production.

Conclusion

CNC machining polycarbonate unlocks the full potential of this remarkable thermoplastic, delivering precision, durability, and versatility. Jiangzhi supplies professional CNC machining service. Ready to start your next project? Contact Jiangzhi for custom PC CNC machining solutions.

FAQ About PC CNC Machining

Yes, polycarbonate (PC) is often more suitable than acrylic (PMMA) for CNC machining due to its higher impact resistance and toughness.

Yes, polycarbonate is widely used in optical applications due to its good transparency and light transmission (about 88-90%).

CNC machining polycarbonate can achieve tolerances as tight as ±0.01 mm, depending on the machine, tools, and part design.

For low to medium volumes or prototyping, CNC machining polycarbonate is more flexible and faster to setup. For very large production runs, injection molding is more cost-effective despite high upfront tooling costs.

Use sharp, polished carbide tools to reduce friction. CNC mills, lathes, or waterjet cutters work well.

Common issues include stress cracking (due to heat), surface scratches, cloudy or melted edges, burrs from dull tools, and dimensional warping.