The injection molding process often faces quality challenges; gas marks are a common defect. This article explores the definition, causes, and prevention methods for gas mark injection molding defects to achieve high-quality production.

What is Gas Mark Injection Molding?

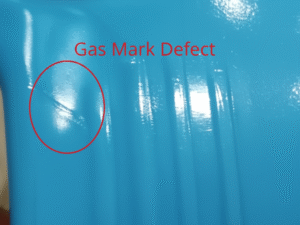

Gas marks are surface defects that occur when gases become trapped inside the mold cavity during injection molding. These gases, which can consist of air, water vapor, or gases released by polymer decomposition, are unable to escape as molten plastic fills the mold. Once the plastic solidifies, the trapped gases create visible blemishes on the surface of the part.

These blemishes may appear as streaks, dendritic or branch-like shapes, ripple patterns, or cloudy and foggy patches. Gas marks are most frequently found near gates, weld lines, or flow endpoints. In addition to affecting the external appearance, these defects can indicate compromised internal structure, reducing the mechanical strength and reliability of the part.

Causes of Gas Marks in Injection Molding

The formation of gas marks stems from multiple interrelated factors. Identifying these causes is essential for effective prevention.

Equipment Factors

Equipment mismatches, such as inappropriate injection machine capacity or poorly designed screws, can disrupt plastic melt flow. Nozzles and barrels with incorrect sizes or surface defects can cause plastic degradation or blockages, entrapping gases. High shear forces within the screw or inconsistent melt temperatures contribute to gas generation.

Mold Design

Poor venting design is a crucial cause. Inefficient or clogged vent channels prohibit trapped air and gases from escaping, allowing pressure build-up and gas entrapment. Mold parting surfaces lacking sufficient venting or mold inserts blocking vents worsen the problem.

Production Process Parameters

High injection pressure or speed compresses gases, forming burn-like streaks, while low pressure extends filling time, trapping air. Insufficient back pressure fails to remove gases from the barrel. Rapid cooling or short fill times lock gases into hazy gas marks, particularly at weld lines.

Material Properties

Hygroscopic resins absorb moisture, which vaporizes during molding, creating cloudy gas marks. High-viscosity polymers trap air due to poor flowability. Overheating causes material decomposition, releasing volatiles that form gas marks. Excessive additives also generate gases.

How to Prevent Gas Mark Defects?

Effective gas mark prevention requires a comprehensive strategy. The following strategies provide practical solutions.

1. Nozzle, Barrel, and Mold Sizing: Use appropriately sized and well-maintained nozzles and barrels to ensure smooth plastic flow without degradation. Mold cavities and runners should be designed to minimize sharp transitions and dead zones where gas can be trapped.

2. Optimize Mold Venting: Install adequately sized and strategically placed vent channels to allow trapped gases to exit freely during injection. Regularly inspect and maintain vents to prevent clogging.

3. Adjust Injection Parameters: Balance injection pressure and speed to reduce gas compression and promote smooth filling. Avoid excessively high injection speeds or pressures that cause rapid gas compression.

4. Temperature Control: Maintain proper barrel and mold temperatures to prevent premature solidification, ensuring gases can escape before the plastic freezes. Use mold temperature controllers if necessary.

5. Material Drying: Thoroughly dry plastic resin before processing using industrial dehumidifying dryers to remove moisture that generates water vapor gas during melting.

6. Additional Measures: Implement cold traps or recirculation cavities to capture residual gases. Increase back pressure to improve melt homogeneity and venting efficiency.

Conclusion

Gas marks in injection molding pose a significant challenge by degrading the appearance and internal strength of plastic parts. However, this defect can be prevented by effective strategies. Jiangzhi has extensive experience in injection molding. We provide tailored strategies to eliminate gas marks. Contact Jiangzhi to get a custom injection molding solution to achieve high-quality, defect-free manufacturing.