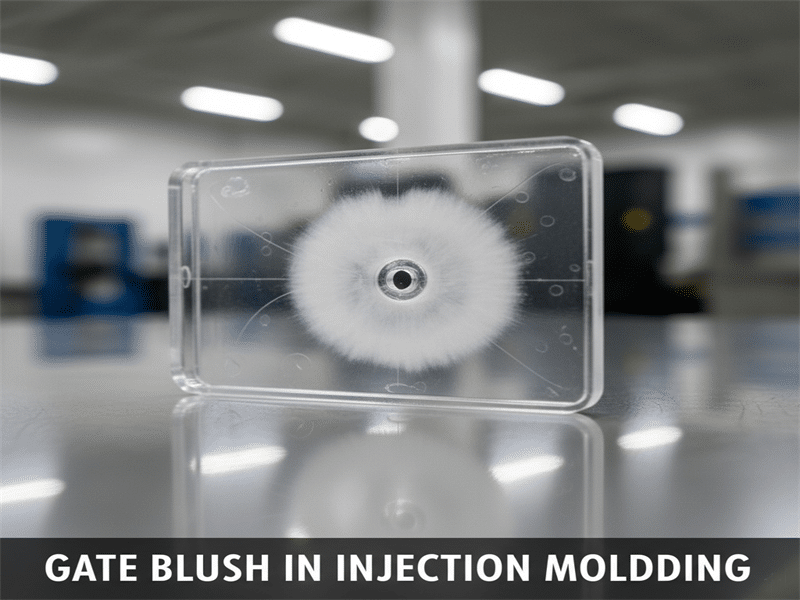

Gate blush injection molding is one common defect that can compromise both the aesthetic appeal and functional integrity of molded components. This injection molding defect can be avoided. In this article, we will explore the causes of gate blush and how to prevent them.

What Is Gate Blush Injection Molding?

Gate blush in injection molding is a surface defect characterized by a milky or frosted appearance near the gate, often with concentric rings or a lighter color compared to the rest of the part. It occurs when molten plastic experiences excessive shear stress or improper flow as it enters the mold, disrupting the material’s molecular structure. Common symptoms include cloudiness, reduced gloss, and visible flow marks, which are most noticeable on dark or glossy parts.

Distinguishing Gate Blush from Similar Surface Defects

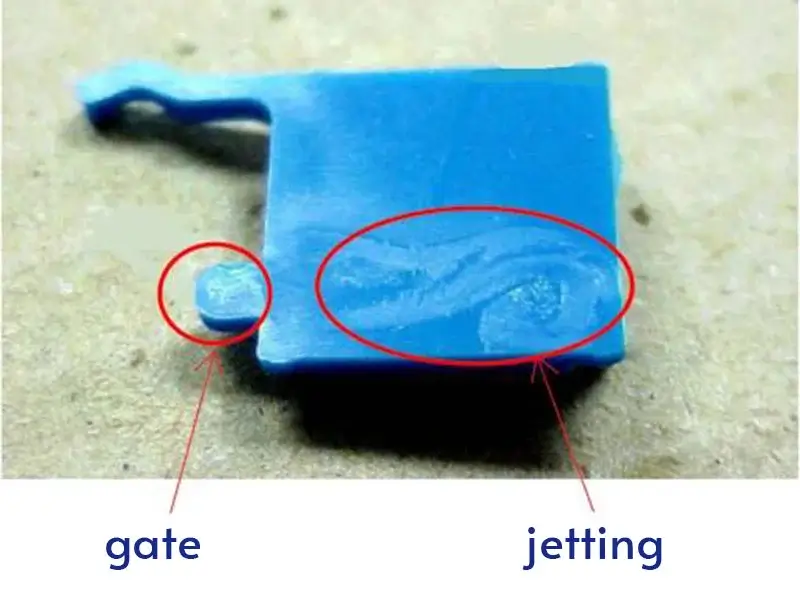

Except for gate blush, there are some other surface defects in injection molding. The other defects have distinct characteristics. Injection molding jetting, for instance, manifests as snake-like flow marks caused by rapid material injection into an open cavity, often with edge gates. Sink marks appear as depressions in thicker sections due to uneven cooling or shrinkage. Splay, another common defect, presents as silvery streaks across the part, typically from moisture or overheated resin. Flow Lines show as wavy or streaky visual patterns resulting from uneven flow fronts, but differ in shape and location from gate blush.

Common Causes of Gate Blush and How to Prevent Them

The formation of gate blush in injection molding arises from a complex set of factors. Preventive strategies focus on controlling these factors before the defect appears during production.

Injection Parameters

High injection speed or pressure is a primary culprit behind gate blush in injection molding. When plastic is forced through the gate too quickly, excessive shear stress generates heat, degrading the material and leaving hazy marks. Conversely, low pressure can cause hesitation, leading to uneven flow and surface imperfections. These issues are common with shear-sensitive materials like polycarbonate or PVC.

To prevent gate blush in injection molding, optimize injection parameters. Start with a slow initial injection speed, gradually increasing to fill the cavity smoothly. Adjust pressure to maintain consistent flow without turbulence. Testing different profiles during setup ensures the material flows evenly, minimizing shear and preventing defects. Regular monitoring of machine settings can further stabilize the process.

Mold and Gate Design

Inappropriate gate size, type, or location often contributes to unbalanced flow and shearing effects. A gate that is too small restricts flow, requiring high pressure and speed, while an excessively large gate may cause material pooling and uneven cooling. Incorrect placement can induce turbulence and stress concentration areas prone to blush formation.

Designing gates tailored to the specific material and part geometry is vital. Selecting gates with adequate size and style to facilitate uniform flow reduces shear stress. Proper gate positioning, combined with mold temperature zoning and venting, helps maintain consistent flow and pressure distribution.

Material Factors

High-viscosity or shear-sensitive resins, such as PC/ABS or PVC, are prone to blushing under high shear. Moisture in resins, especially hygroscopic ones, can vaporize during molding, creating surface defects. Degraded recycled materials may also disrupt flow consistency.

To mitigate gate blush in injection molding, choose materials with better flow properties for the specific application. Thoroughly dry resins before molding to eliminate moisture, using a desiccant dryer if necessary. Adjusting material grades or formulations for better flow and temperature tolerance supports improved surface quality.

Other Factors

Additional factors can trigger gate blush in injection molding. Small nozzle diameters increase flow resistance, intensifying shear at the gate. Improper mold coatings or residue buildup from previous runs can affect surface finish, contributing to haze. Inconsistent process cycles, often from manual operation errors, lead to variations in temperature or pressure.

Preventing these issues involves practical adjustments. Match the nozzle diameter to the sprue bushing size to ensure smooth flow. Regularly clean molds to remove residue and maintain proper coatings, such as mold release agents or anti-stick layers. Automate process cycles to stabilize conditions, and use temperature controllers to keep mold temperatures consistent, reducing the likelihood of gate blush in injection molding.

How to Solve Gate Blush Problems After They Occur?

Addressing gate blush injection molding defects once they occur requires systematic detection and targeted intervention based on root cause.

Detecting Gate Blush

Visual inspection remains the primary method for identifying gate blush, focusing on surface texture and color near gate locations. Advanced optical or surface profilometry tools can assist in quantifying gloss and haze variations, supporting objective assessment. Differentiating gate blush from other defects at this stage guides appropriate solutions.

Solutions for Specific Causes

Once gate blush in injection molding is detected, targeted solutions address its root causes. The following table outlines common issues and their fixes:

| Cause | Solution |

|---|---|

| High injection speed | Reduce initial speed, gradually increase to fill cavity smoothly |

| Small or restrictive gate | Enlarge gate size, consider fan or submarine gates for better flow |

| Improper mold temperature | Adjust to material-specific range (e.g., higher for PC/ABS, lower for PVC) |

| Poor venting | Add vents (0.0005–0.002 inches deep) to release trapped air |

Conclusion

Gate blush in injection molding leads to rejected parts, increased production costs, and damaged reputations. As a professional and experienced manufacturer, Jiangzhi resolves gate blush and achieves high-quality molded parts. Contact Jiangzhi and get a custom injection molding solution.

FAQ

High-viscosity or shear-sensitive materials like PC/ABS, polycarbonate, and PVC are most prone to gate blush in injection molding due to their sensitivity to shear stress and flow disruptions.

As a quick fix method, one common approach is to reduce the injection speed (especially at the start of filling) to lower shear stress and allow smoother material flow. Increasing the gate size or optimizing gate design can also help lessen the issue.