When producing custom rubber and plastic components, selecting the appropriate manufacturing scale is a key decision. The choice between high volume manufacturing and low volume manufacturing directly affects costs, lead times, design flexibility, and project success. This decision depends on production quantity, product development stage, and market demand.

What is Low Volume Manufacturing?

Low volume manufacturing refers to the production of a smaller number of parts or components. Typically, this is defined as production runs of fewer than 10,000 units. Low volume manufacturing is often used for prototypes, limited edition products, or specialized components that do not require large-scale production. This approach provides several advantages, particularly for applications that need flexibility and customization in their products.

The Advantages of Low Volume Manufacturing

The process allows manufacturers to create small batches that can be modified or adjusted throughout the production cycle, giving them the ability to refine the design based on feedback and real-world performance. Additionally, low volume manufacturing is ideal for testing products before committing to large-scale production.

The Disadvantages of Low Volume Manufacturing

Since the production runs are small, it is easier to make adjustments without incurring the significant costs associated with mass production. However, the downside is that the unit cost tends to be higher due to the lower economies of scale.

What is High Volume Manufacturing?

High volume manufacturing involves producing large quantities, generally starting from 10,000 units and scaling to hundreds of thousands or millions of pieces. This method is best suited for products with stable, high demand, such as automotive parts, consumer electronics enclosures, or rubber components. This method is characterized by its efficiency in producing large numbers of identical components with minimal variation.

The Advantages of High Volume Manufacturing

The key advantage of high volume manufacturing is its ability to significantly reduce the per-unit cost. With large production runs, manufacturers can take advantage of economies of scale, lowering the overall cost per unit.

The Disadvantages of High Volume Manufacturing

However, the trade-off is a lack of flexibility. High volume production is less suitable for products that require customization or design modifications during the manufacturing process. Additionally, the initial investment in tooling and setup can be significant, making it impractical for projects that do not have a long-term need for large quantities of the same product.

High Volume vs Low Volume Manufacturing Comparison

To help better understand the differences between low volume and high volume manufacturing, the following table compares various factors associated with each method:

| Factor | Low Volume | High Volume |

|---|---|---|

| Quantity Range | 1 – 10,000 units | 10,000+ units |

| Unit Cost | Higher due to smaller runs | Lower due to scale |

| Tooling Cost | Lower (aluminum / prototype molds) | Higher (durable steel molds) |

| Design Flexibility | High, can customize | Low, less flexibility |

| Lead Time | Longer setup time | Faster production rates |

| Quality Consistency | Good (often manual checks) | Excellent (highly automated) |

| Ideal Use Case | Prototyping, testing | Mass production |

Common Manufacturing Processes

Some processes are used in low-volume manufacturing, some are used in high-volume manufacturing.

Processes Used in Low Volume Manufacturing

Low-volume production prioritizes speed, flexibility, and lower initial investment. The following processes are frequently applied:

Aluminum Mold / Prototype Tooling Injection Molding

Aluminum molds are softer and faster to machine than steel, making them suitable for prototype runs and small batches (typically up to a few thousand shots). Ideal for testing plastic housings, connectors, or custom rubber-like TPE parts.

Compression Molding

Widely used for custom rubber parts such as EPDM seals, silicone gaskets, or NBR oil seals in low to medium quantities. Tooling is relatively inexpensive and allows quick material and design adjustments.

Low-Pressure Injection Molding

Suitable for soft materials and small runs of plastic or rubber-like components. It reduces mold stress and is often used for overmolding or insert molding in early development stages.

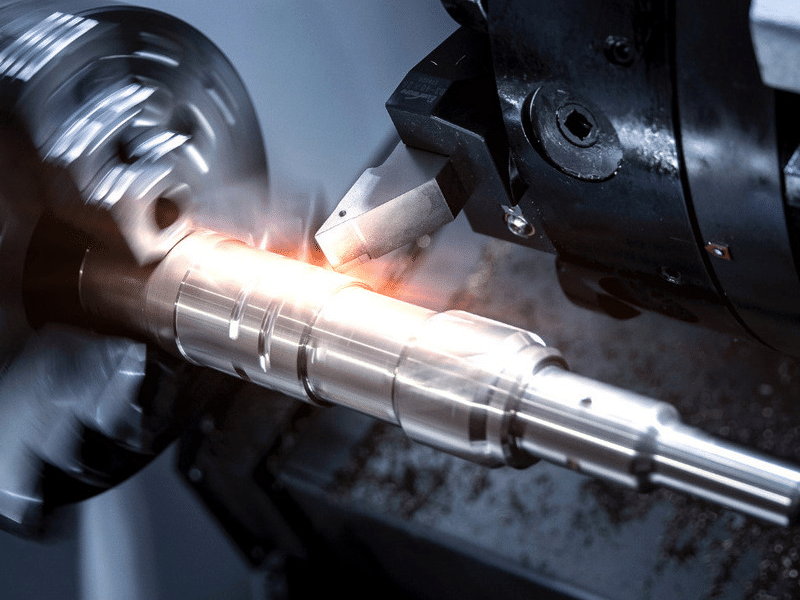

CNC Machining

CNC machining is one of the most common methods for low-volume production of custom rubber and plastic parts. No molds are required, which eliminates tooling costs and allows for very fast turnaround times. It is ideal for prototypes, functional testing parts, and small batches.

Processes Used in High Volume Manufacturing

High-volume production focuses on speed, durability, and cost efficiency per unit. The following processes dominate when quantities exceed 10,000–50,000 pieces:

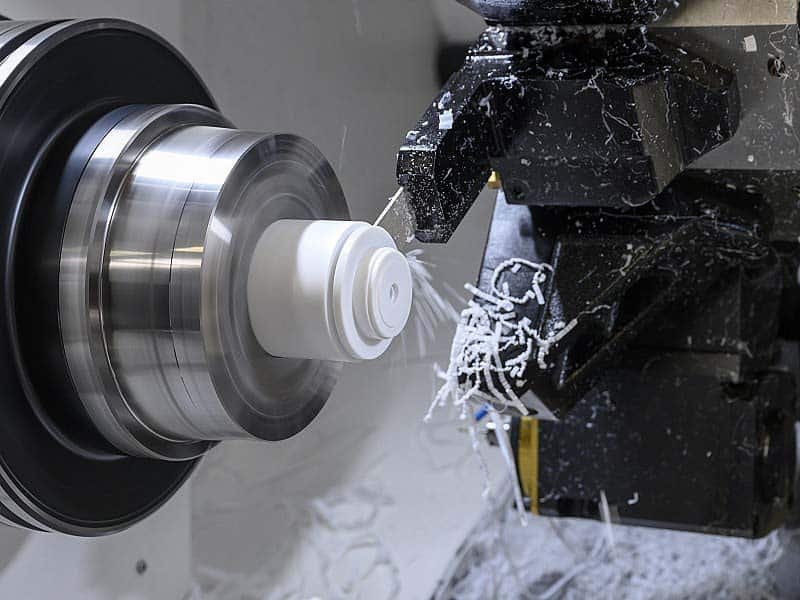

Multi-Cavity Steel Mold Injection Molding

High-grade steel molds with multiple cavities enable the simultaneous production of many parts per cycle. This is the standard process for mass production of plastic housings, automotive interior components, and consumer product parts.

High-Volume Rubber Compression Molding

Fully automated lines with multiple presses and robotic handling produce rubber parts (such as engine mounts or vibration dampers) at high speed and with tight tolerances.

Conclusion

The decision between high volume manufacturing and low volume manufacturing should be based on the specific needs of the custom plastic parts and rubber parts project. Choose right manufacturer is also important. Jianzhi, a professional manufacturer specializing in custom rubber and plastic components, offers a solution tailored to both low and high volume production.