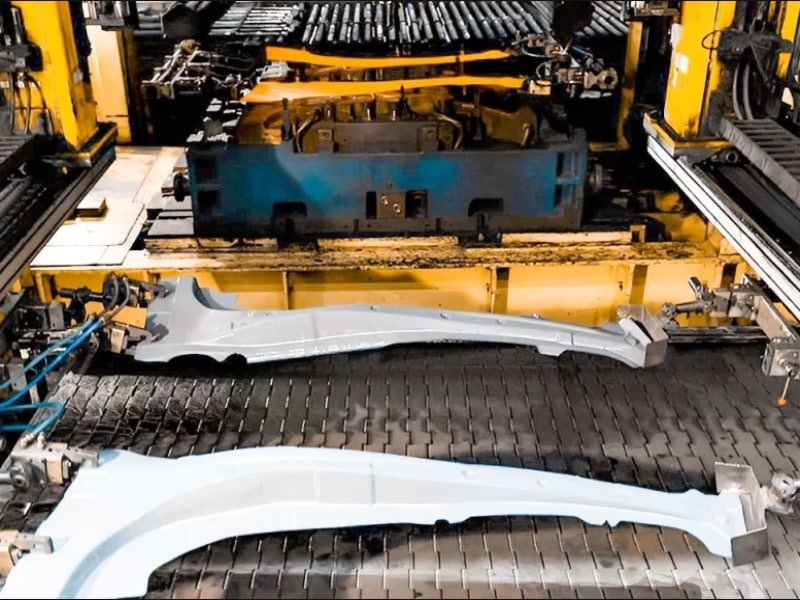

Nomatter the sleek smartphone casing or non-slip grip, both aesthetic and functional injection parts surfaces stem from a critical aspect of manufacturing: injection molding surface finishes. In the world of injection molding, the surface finish of a part can make or break its success, influencing everything from visual appeal to production efficiency. The surface finish of an injection molded part is determined by the texture and polish of the mold finish, which transfers its characteristics to the molded part during the injection process. This guide dives deep into the types, standards, and considerations of injection molding finishes.

What Is Injection Molding Surface Finishes?

Injection molding surface finishes refer to the final texture and appearance of a plastic part’s surface as it comes out of the mold. In injection molding, the surface finish is created directly by the mold surface itself. The mold cavity is prepared with specific textures or polishing so that when molten plastic is injected and solidifies, the part inherits that exact surface finish. Injection molding surface finishes are the direct result of the mold surface preparation, governed by standards like SPI and VDI, and play a vital role in defining the final product’s quality, appearance, and functionality.

Types of Surface Finishes

The diversity of injection molding finishes allows manufacturers to tailor parts to specific needs. Here’s a breakdown of the primary categories:

Polishing

Polishing involves mechanically, chemically, or electrochemically smoothing the mold surface to reduce roughness, resulting in a glossy and smooth plastic part surface. Depending on the polishing level, it ranges from mirror polishing (such as SPI Grade A) to semi-polishing (SPI Grade B). Mirror polishing produces a high-gloss, mirror-like finish ideal for transparent parts and premium appearance components. Polishing not only enhances aesthetics but also helps reduce molding defects like flow marks and weld lines.

Textured

Texturing creates various patterns or roughness on the mold surface to achieve specific visual and tactile effects. Common textures include leather grain, silk grain, and pebble finishes. Textured surfaces improve grip and tactile feel while effectively hiding mold parting lines, sink marks, and other imperfections. The depth of texture affects gloss level—shallow textures maintain some sheen, whereas deeper textures produce matte or rough finishes.

Matte and Semi-Gloss Finishes

Matte finishes are achieved by abrasive methods such as stone or sandpaper polishing, resulting in low-gloss, non-reflective surfaces. These finishes provide a soft touch and reduce glare, making them suitable for automotive interiors, electronic housings, and other applications where subtle aesthetics are desired. Semi-gloss finishes fall between matte and glossy, offering a balance of sheen and texture.

Other Special Coatings and Platings

Advanced finishes like electroplating or specialty paints add unique properties, such as metallic sheen or enhanced durability.

Painting: Applying liquid paint layers to enhance protection and decoration. Painting offers rich color options and is widely used in appliances and automotive parts.

Powder Coating: Spraying dry powder that is baked to form a durable, wear-resistant surface layer, more resilient than traditional painting.

Electroplating: Depositing a thin metal layer (such as chrome or nickel) onto the plastic surface to improve wear resistance, corrosion protection, and visual appeal. Common in decorative parts.

Industry Standards for Injection Molding Surface Finishes

Injection molding surface finishes are standardized to ensure consistency and quality. The most widely recognized and utilized standard is the SPI surface finish system, established by the Society of the Plastics Industry (SPI).

SPI Surface Finish Standard

Glossy Finishes (Category A):

These are the highest polish levels, achieved through diamond buff polishing. Grades such as A-1, A-2, and A-3 correspond to progressively less fine polishing, with surface roughness (Ra) values ranging from approximately 0.012 µm to 0.03 µm. These finishes produce mirror-like surfaces ideal for optical clarity and high-end aesthetic applications.

Semi-Glossy Finishes (Category B):

Semi-gloss finishes are created using fine abrasive papers (600 to 320 grit). The surface roughness increases compared to glossy finishes, typically between 0.05 µm and 0.1 µm Ra. These finishes balance smoothness and cost-effectiveness, suitable for many consumer products requiring moderate shine.

Matte Finishes (Category C):

Matte finishes are produced by stone polishing with coarser abrasives, resulting in roughness values from about 0.35 µm to over 1 µm Ra. These finishes reduce glare and help mask minor mold imperfections, making them popular for automotive interiors and functional parts.

Textured Finishes (Category D):

Textured finishes involve abrasive blasting methods such as glass bead or aluminum oxide blasting, producing rough surfaces with Ra values ranging from around 1 µm to over 18 µm. These finishes improve grip, hide defects, and reduce reflective glare. They require careful mold design, especially regarding draft angles.

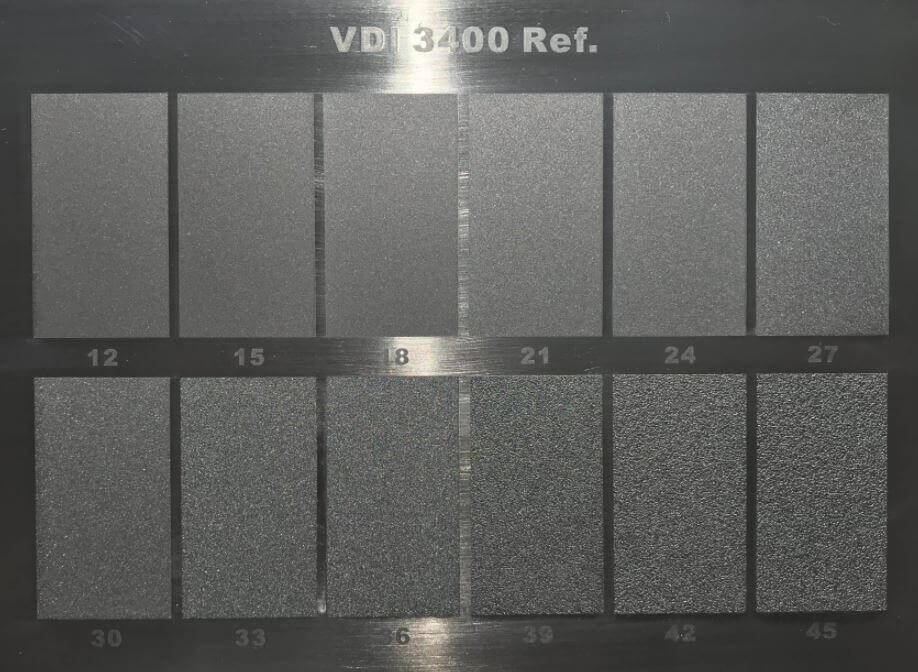

VDI Surface Finish Standard

Originating from the German engineering association Verein Deutscher Ingenieure (VDI), VDI grades (12 to 45) focuses on surface roughness achieved mainly through Electrical Discharge Machining (EDM). VDI finishes are often used for matte surfaces with controlled roughness and are common in European manufacturing.

Mold-Tech Finishes

Mold-Tech offers commercially available textured finishes with specific patterns and depths, widely used in consumer goods for consistent, repeatable textures. These finishes complement SPI and VDI standards by providing industry-tested texture options.

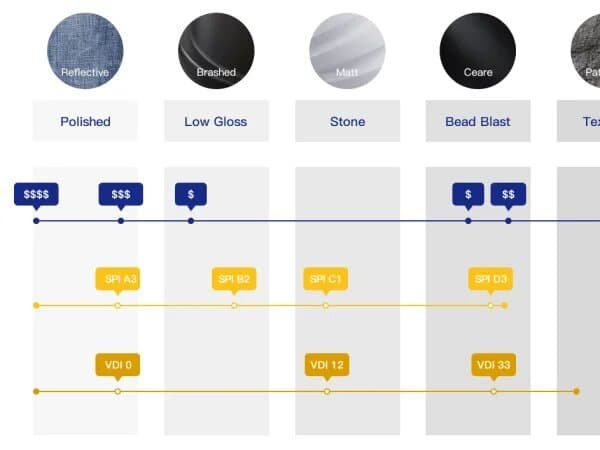

Here is a tabel to compare three standards:

| Standard | Focus | Common Use Cases |

|---|---|---|

| SPI | Polished to textured | Optical parts, consumer goods |

| VDI 3400 | Textured finishes | Automotive, industrial |

| Mold-Tech | Custom textures | Consumer products, automotive |

Impact of Surface Finishes on Product Design

The choice of mold finish profoundly shapes product design, influencing both performance and manufacturability.

Part Release and Production Efficiency

Different surface finishes will affect the part release and production efficiency. Polished surfaces facilitate smooth release, reducing cycle times and boosting efficiency. Conversely, heavily textured finishes may increase sticking, requiring draft angles or release agents to prevent defects.

Visual and Tactile Performance

The aesthetic and tactile qualities of a part hinge on its surface finish. A glossy SPI surface finish can make a product appear luxurious, ideal for premium electronics. Textured finishes, like those in Mold-Tech standards, enhance grip, as seen in tool handles or medical devices.

Influence on Secondary Processes

A smooth mold finish SPI A2 surface ensures better adhesion for coatings. Textured finishes, while effective at hiding defects, may require specialized primers to ensure paint compatibility. So, understanding these interactions early in design is very important.

How to Choose the Right Surface Finish for Injection Molding

Selecting the optimal injection molded part surface finish is a delicate dance between form, function, and cost.

Product Functionality and Aesthetics

The finish must align with the part’s purpose. Transparent or decorative parts often demand SPI A or B finishes for clarity and shine. Functional parts needing grip or reduced glare benefit from matte or textured finishes like SPI C or D.

Mold Life and Production Costs

Polished mold finishes increase tooling time and cost but yield superior surface quality. Textured finishes generally reduce polishing time and extend mold life but may necessitate design adjustments to accommodate draft angles.

Material Compatibility with Surface Finishes

Not all materials play well with every finish. Polycarbonate excels with polished mold finish SPI grades for optical clarity, while ABS pairs well with textured finishes to mask flow lines.

Mitigating Injection Molding Defects Through Surface Finish Optimization

Surface finish selection can mitigate common injection molding defects. Textured finishes enhance venting by providing micro-channels for trapped gases, reducing burn marks and voids. Polished finishes help prevent knit lines and flow marks by promoting uniform melt flow and minimizing surface tension variations.

Moreover, appropriate mold finish reduces the risk of weld lines, sink marks, and flow hesitation by ensuring consistent cooling and mold filling dynamics. The right surface finish can also mitigate cosmetic defects such as orange peel or surface blemishes, enhancing the overall quality of the injection molded part surface finish.

Conclusion

When you’re working on a plastic part, the surface finish is something that’s often easy to overlook at first — but it actually matters a lot. It affects how the part looks, how it feels, and even how smoothly it goes through production. The earlier you figure this out during the injection molding design, the better. Different finishes can lead to different mold designs or even change which materials make the most sense. That’s where a dependable injection molding manufacturer can really help. At Jiangzhi, we’re used to thinking about these details with our clients. If you’ve got a project in mind, let’s talk — we’ll help you get it made the right way.