Injection molding vs 3D printing debates often arise when selecting the right method for a project. Generally, large-volume production relies on injection molding for efficiency, while small-batch or prototype work favors 3D printing. The differences stem from setup requirements, output capabilities, and overall economics. How should one choose between plastic injection molding vs 3D printing?

What is Injection Molding?

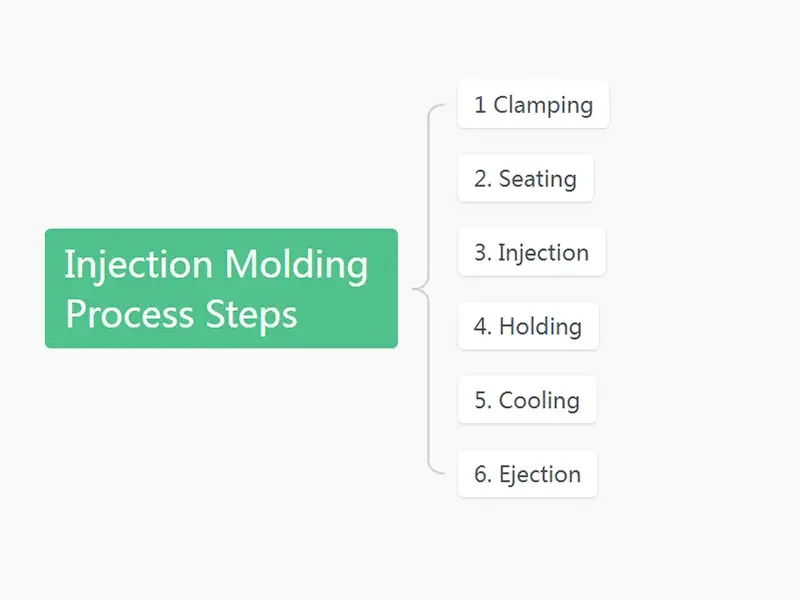

Injection molding involves melting plastic pellets and injecting the material into a mold cavity under high pressure. The process flow includes designing the mold, heating the plastic in an injection unit, forcing it into the mold, cooling the part, and ejecting the finished component. Trimming or secondary operations may follow.

The commonly used injection molding materials include ABS, polycarbonate, polypropylene, and polyethylene. Additives like glass fibers enhance properties.

Advantages of Injection Molding

- Low Per-unit Cost: large-scale production will low the per unit cost after amortization.

- High Production Efficiency: After mold fabrication, thousands of parts can be produced rapidly.

- Great Accuracy and Repeatability: Every molded part maintains consistent geometry.

- Wide Material Selection: Compatible with various engineering plastics and composites.

- Superior Surface Finish: Produces parts with smooth surfaces or fine textures directly from the mold.

Disadvantages of Injection Molding

- High Initial Investment: Mold fabrication is expensive and time-consuming.

- Longer Setup Time: Design changes or mold adjustments take effort and cost.

- Less Cost-Effective for Small Batches: The per-part cost is high at low volumes due to tooling expenses.

What is 3D Printing?

3D printing, or additive manufacturing, builds parts layer by layer from digital models. The workflow starts with CAD design, slicing the model into layers, and executing the print via technologies like FDM (fused deposition modeling) for thermoplastics, SLA (stereolithography) for resins, or SLS (selective laser sintering) for powders.

Materials range from PLA for ease of use, PETG for durability, nylon for flexibility, TPU for elasticity, to resins or metal-infused filaments.

Advantages of 3D Printing

- High Design Freedom: Can produce intricate geometries and internal structures impossible with molding.

- Low Startup Cost: No molds required, ideal for prototypes and small batches.

- Fast Iteration: Designs can be modified and reprinted in hours.

- Reduced Waste: Material usage is limited to the printed part.

Disadvantages of 3D Printing

- Slower Production Speed: Not suitable for high-volume manufacturing.

- Limited Material Properties: Printed parts often have lower strength than molded ones.

- Surface Finish Variation: Additional post-processing is often required.

- Dimensional Inconsistency: Accuracy depends on printer calibration and material type.

Key Comparison Between Injection Molding and 3D Printing

Both processes can produce functional plastic components, but their approaches, economics, and material outcomes differ significantly. The following table summarizes the main distinctions between 3D printing and injection molding.

| Aspect | Injection Molding | 3D Printing |

|---|---|---|

| Initial Cost | High (mold fabrication required) | Low (no tooling) |

| Per-Part Cost | Low at high volume | High at high volume |

| Production Speed | Fast for large runs after mold setup | Slow, especially for multiple parts |

| Development Time | Longer (requires mold design and testing) | Short (direct from digital file) |

| Materials and Mechanical Performance | Wide range, isotropic strength, high durability | Varied but anisotropic, 80-110% molded strength in optimized cases |

| Design Complexity | Limited by mold release, needs even walls | Unlimited, supports lattices and internals |

| Surface Treatment and Precision | Smooth out-of-mold, ±0.02mm tolerances | Requires sanding/polishing, layer lines visible |

| Consistency and Scalability | Excellent for high volumes, uniform batches | Good for low-mid volumes, potential variation |

| Sustainability | Generates more waste (runners, sprues) | Minimal waste during production |

How to Choose Injection Molding vs 3D Printing?

The selection between injection molding vs 3D printing hinges on project specifics.

1. Production Volume:

For low-volume production (fewer than a few hundred units), 3D printing minimizes upfront costs. For mass production, injection molding provides a lower cost per unit and better efficiency.

2. Material Performance:

Injection molding offers superior mechanical strength and thermal resistance, making it ideal for load-bearing parts. 3D printing vs injection molding strength comparisons consistently show that molded parts outperform printed ones in durability and impact resistance.

3. Design Flexibility:

3D printing enables complex internal channels and lattice structures without tooling constraints. Injection molding, while more limited in geometry, ensures consistent dimensional accuracy for simple or moderate designs.

4. Lead Time and Iteration:

If the project is still in the prototype stage, 3D printing offers unmatched speed. For finalized designs, injection molding delivers repeatable, production-ready parts.

5. Cost Considerations:

Injection molding vs 3D printing cost depends heavily on volume. The initial tooling investment for molding is high, but amortized over thousands of parts. For rapid prototyping, 3D printing vs injection molding cost favors additive manufacturing due to its low startup barrier.

In many cases, both methods are complementary rather than competitive. Companies often use 3D printing to create prototypes or even mold inserts, then transition to injection molding once the design is validated. This hybrid approach shortens development cycles while maintaining production efficiency.

Conclusion

Future trends in 2025 point to hybrid manufacturing, with faster 3D printers and smarter molding automation blurring lines. Multi-material printing and Industry 4.0 integration will expand options. Choose based on volume, complexity, budget, and requirements. Jiangzhi offers professional injection molding services as a one-stop contract manufacturer, from design to delivery. Welcome to contact Jiangzhi and get a custom solution for your project.