The parting line injection molding plays a critical role in plastic part design, as it significantly affects the quality, functionality, and aesthetics of the molded component. Understanding what a parting line is and how it forms is essential for avoiding defects and achieving optimal design outcomes.

What Is the Parting Line Injection Molding and How Is It Formed?

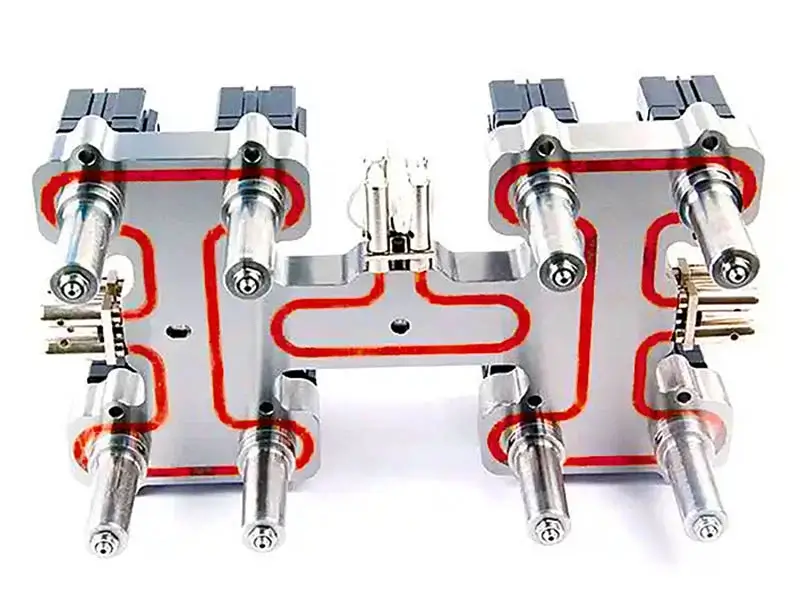

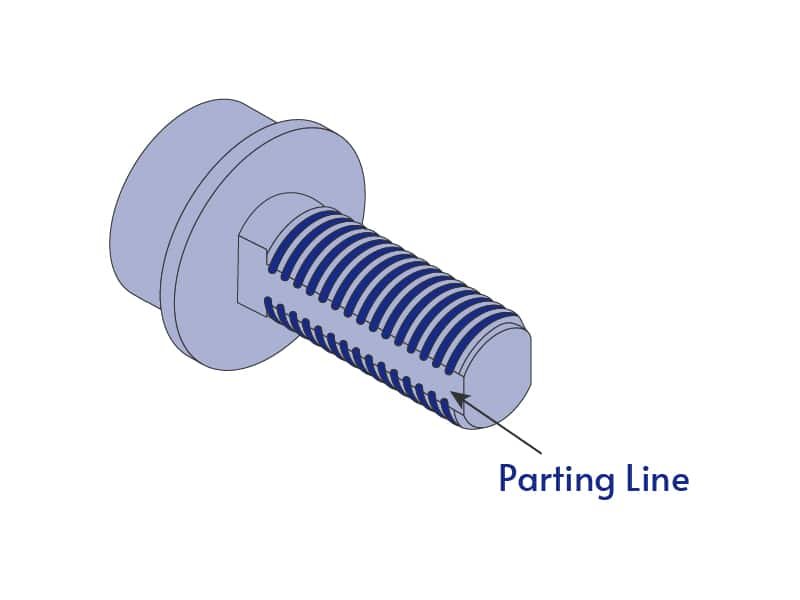

At its core, the parting line in injection molding refers to the physical boundary or seam where the two halves of a mold—known as the core and cavity—meet and separate during the molding process. When molten plastic is injected into the mold, it fills the cavity formed between these halves. Once the plastic cools and solidifies, the mold opens along the mould parting line to eject the finished plastic part. The injection molding parting line is a natural and unavoidable feature of the molding process; Its location, orientation, and design can be optimized.

Because the mold halves can never achieve a perfect, gap-free seal, a visible line known as the plastic parting line appears on the surface of the molded component.

Why is the Parting Line Location Important?

The location of the parting line in plastic molding affects aesthetics, functionality, and manufacturing efficiency. A poorly chosen mould parting line can lead to a cascade of problems.

Aesthetic Considerations

A plastic parting line that runs across a visible surface can create an unsightly seam, detracting from the product’s appeal. Poor placement may require secondary finishing processes, which increase production costs and time.

Functional Implications

Beyond aesthetics, the mould parting line impacts the part’s performance. If the line intersects critical features, it can introduce weaknesses or dimensional inaccuracies.

Manufacturing Efficiency

The injection moulding parting line also influences production efficiency. A well-positioned parting line minimizes the need for complex mold features, such as side cores or sliders, which add cost and maintenance demands. It also reduces cycle times by allowing smoother mold opening and part ejection.

Types of Parting Lines in Injection Molding

The diversity of part geometries in injection molding necessitates various types of parting lines in injection molding. Each type is tailored to specific design requirements, ensuring effective mold separation and part release.

Flat/Standard Parting Line

The simplest form, a flat parting line in injection molding, lies on a single plane, ideal for straightforward shapes like flat panels or rectangular boxes. Its simplicity minimizes mold complexity and cost, making it a go-to for basic designs.

Stepped Parting Line

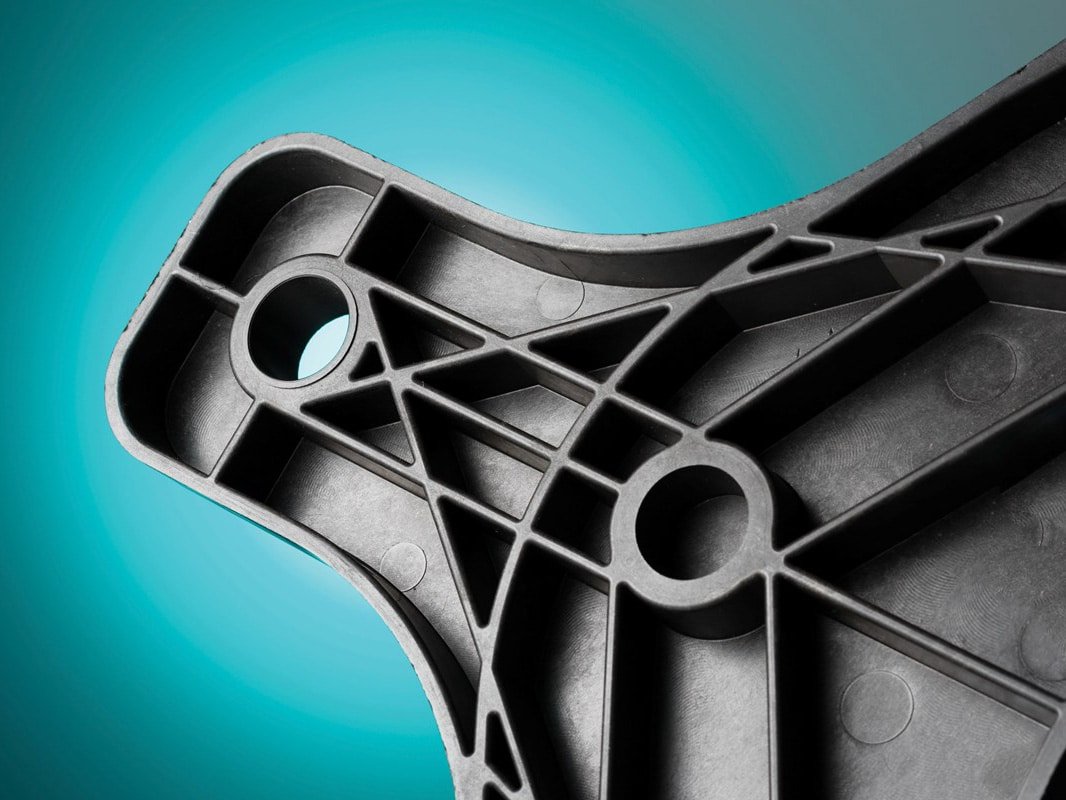

For parts with varying heights or stepped surfaces, a stepped mould parting line follows multiple planes. This type accommodates more complex geometries, such as enclosures with raised features, but requires precise mold alignment to avoid defects.

Curved/Complex Parting Line

When dealing with intricate or contoured parts, such as curved casings or organic shapes, a curved parting line in plastic molding traces the part’s outer profile. This type demands advanced mold design and engineering to ensure seamless mold separation.

Vertical Parting Line

Used for tall or cylindrical parts, a vertical injection moulding parting line allows the mold to split along the part’s height. This is common in products like bottles or containers, where vertical separation simplifies demolding.

Side Parting Line

For parts with undercuts or side features, a side parting line incorporates sliders or side cores. While effective for complex designs, this type increases mold complexity and cost, requiring careful planning.

Parting Line Design Principles

Designing an effective parting line in injection molding requires adherence to several key principles.

Position at Maximum Cross-Section

Place the parting line in plastic molding at the part’s largest cross-sectional area to facilitate smooth demolding. This reduces stress on the mold and minimizes the risk of part damage during ejection.

Prioritize Aesthetics and Functionality

Avoid placing the injection moulding parting line on critical surfaces, such as visible areas or functional features like seals or mounting points. This preserves the part’s appearance and performance.

Incorporate Draft Angles

Include draft angles (typically 1-2 degrees) on vertical surfaces to ease part release. A well-designed draft reduces friction, prolongs mold life, and ensures a clean plastic parting line.

Minimize Side Cores and Sliders

Limit the use of side cores or sliders, as they increase mold complexity and cost. When unavoidable, optimize their travel distance to maintain efficiency.

Ensure Coaxial Precision

For parts requiring tight tolerances, such as gears or connectors, place coaxial features in one mold half to maintain alignment and avoid dimensional errors along the mold parting line.

Optimize Mold Opening Stroke

Design the parting line in injection molding to minimize the mold’s opening distance. A shorter stroke speeds up production cycles and reduces energy consumption.

Balance Clamping Forces

Position the mould parting line to distribute clamping forces evenly, especially for large parts. This prevents flash and ensures mold durability.

Conclusion

The parting line in injection molding is a critical element in injection molding design guide that shapes the success of every molded part, balancing aesthetics, functionality, and production efficiency. Jiangzhi’s expertise in selecting the right types of parting lines in injection molding can craft optimal parting lines that elevate part quality and streamline production. Welcome to contact us and get a mold design and plastic injection molding solution.