From everyday items like toothbrushes to automotive components such as interior handles, plastic overmolding fuses two or more materials into a single, integrated part during manufacturing. This process streamlines production by molding the second material directly onto the first substrate, eliminating separate assembly steps and enabling enhanced functionality, durability, and ergonomics in modern plastic products.

What is plastic overmolding?

Plastic overmolding is a multi-step injection molding process in which a base plastic part is molded first, and then a second material is injected over it to form a permanent bond. In a conventional single-shot injection molding process, the mold is filled once with one type of plastic material, producing a part made of a single material. In plastic overmolding, the part is produced in at least two stages, and the second material is carefully chosen to adhere to the substrate and provide additional functions such as grip, cushioning, or sealing. This process is widely adopted because it supports more sophisticated product designs, integrates multiple functions into one component, and can simplify downstream assembly.

Plastic overmolding process flow

The plastic overmolding process is a multi-step procedure. Although specific production setups vary, the plastic overmolding process generally follows a similar set of steps:

Injection of the Base Material

The first material, usually a rigid plastic, is injected into the mold. This base material forms the core of the product and provides its structure and strength. In some cases, the base material may be pre-formed into a part before the overmolding process begins.

Substrate placement for overmolding

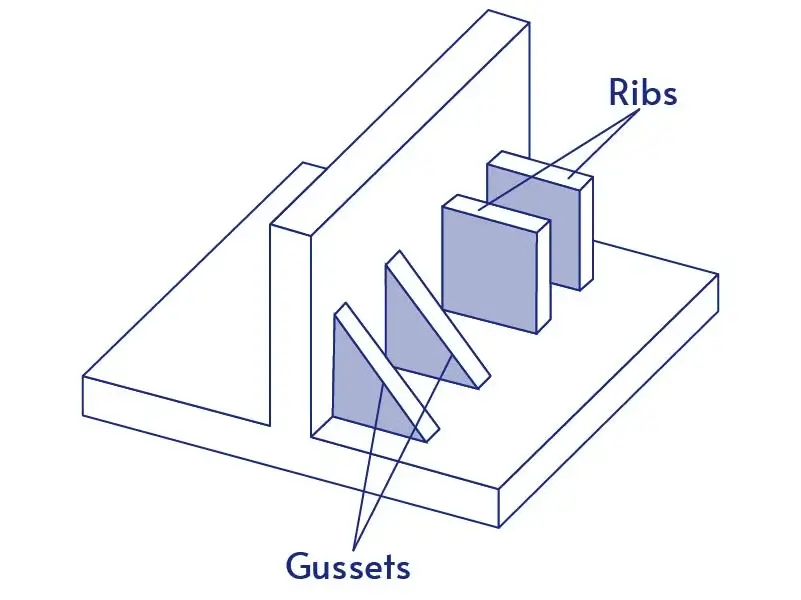

The molded substrate is positioned in the overmolding cavity either manually or by a robot. Accurate positioning and alignment with features such as ribs, holes, and logos are important. Depending on the material type, the substrate may need to be cleaned, preheated, or coated to ensure proper adhesion with the overmolding layer.

Overmolding Application:

The second material, typically a softer plastic or elastomer, is injected into the mold to cover the substrate. The overmolding layer bonds to the base material, creating a single, integrated component.

Cooling and Removal

Once the overmold has been applied, the mold is cooled to solidify the materials. The finished part is then removed from the mold and subjected to any necessary post-processing, such as trimming or inspection.

Common Materials Used in Plastic Overmolding

Plastic overmolding involves the use of two primary materials: the base material (substrate) and the overmold material. The choice of materials significantly impacts the performance, cost, and application of the final product.

Substrate Plastics

The substrate in plastic overmolding usually provides structural strength, dimensional stability, and basic mechanical performance. Common substrate materials include:

ABS: widely used in consumer electronics housings and general-purpose parts due to its balanced toughness and good processability.

PC and PC/ABS blends: chosen for parts that require higher impact resistance and better heat performance, such as protective covers and interior automotive components.

PA (nylon): used in automotive, industrial, and mechanical parts that need high strength, fatigue resistance, and resistance to oils or chemicals.

PP: applied in applications where low density, chemical resistance, and cost efficiency are important, such as containers and certain appliance components.

Overmold Materials

The overmold layer is typically a softer or more flexible material that improves user interaction or adds protective functions. In plastic overmolding, common overmold materials include:

TPE and TPV: thermoplastic elastomers used for soft-touch grips, buttons, seals, and impact-absorbing regions. They are available in a wide range of hardness levels and colors.

TPU: thermoplastic polyurethane selected for applications requiring high abrasion resistance, good flexibility, and resistance to oils and fuels, such as protective cases and tool handles.

Other Elastomers and Soft Plastics: Depending on regulatory and performance requirements, alternative materials can be used in less demanding environments.

Importance of Material Compatibility

Successful plastic overmolding relies heavily on proper matching between the substrate plastic and the overmold material. Material compatibility affects adhesion strength, dimensional stability, and long-term reliability.

Chemical Compatibility: the polymers must be able to bond at a molecular level or be used together with appropriate adhesion promoters or tie layers.

Thermal Behavior: differences in melt temperature, heat deflection temperature, and thermal expansion can lead to stress at the interface and premature failure if not controlled.

Processing Conditions: the overmold material must be processed at a temperature and pressure that do not deform or degrade the substrate, while still providing good flow and bonding.

Advantages and Disadvantages of Plastic Overmolding

Plastic overmolding offers several advantages compared with single-shot injection molding and assembly of multiple separate parts:

Advantages of Plastic Overmolding

- Integrated structure: components are formed as a single unit, reducing or eliminating the need for adhesives, screws, or mechanical fasteners. This can improve structural integrity and reduce assembly time.

- Improved ergonomics: soft-touch areas, non-slip surfaces, and contoured grips can be integrated directly into the product, improving comfort and usability.

- Functional enhancements: overmolded seals, gaskets, and protective layers can enhance water resistance, dust protection, vibration damping, and impact resistance.

- Design flexibility and appearance: multi-color and multi-material combinations allow distinctive visual designs and brand differentiation while maintaining a consistent structure.

- Potential cost savings: Despite higher tooling complexity, plastic overmolding can lower total cost per unit by combining functions and reducing secondary assembly processes.

Disadvantages of Plastic Overmolding

- Higher tooling and development complexity: molds must support multiple materials and stages, and design changes are more costly once tooling is built.

- Material selection constraints: not all material combinations are suitable for plastic overmolding, and in some cases, adhesion or durability may be insufficient.

- Narrow process window: parameters such as temperature, injection speed, and cooling must be carefully controlled to avoid defects like warpage, burns, or weak bonding.

- Equipment and automation requirements: high-volume projects may require specialized injection molding machines or automated handling systems to manage substrate transfer and positioning.

Applications of Plastic Overmolding

Plastic overmolding is used across a variety of industries to create parts and products.

Automotive: Overmolding produces components such as handles, grips, and seals to enhance the product’s comfort, durability, and resistance to wear.

Medical Devices: In the medical field, plastic overmolding is used to create components such as ergonomic grips, protective covers, and seals for medical devices to improve the comfort and functionality of devices while maintaining high standards for safety and hygiene.

Consumer Electronics: Overmolding is widely used in the production of products such as mobile phone cases, remote controls, and headphones to create products that are both durable and comfortable to use.

Sporting Goods: Overmolding is also used to create grips, handles, and other components that require a combination of strength and flexibility.

Conclusion

Plastic overmolding allows for the integration of different materials into a single component to reduce assembly steps and achieve more reliable and attractive products. Properly chosen base and overmold materials ensure a strong bond and long-lasting performance.

At Jianghzi, we are committed to helping our clients choose the right materials for their plastic overmolding service needs and providing end-to-end services, from mold design to mass production. Whether you’re in need of custom solutions or large-scale manufacturing, we can support your product development from start to finish.