Plastics play a critical role in a wide range of industries, from automotive manufacturing to medical devices and consumer goods. Polycarbonate and polypropylene are two widely used thermoplastics that often appear in the same short list of candidate materials, but they serve very different purposes. Both materials offer distinct advantages, but understanding their differences can help you make an informed decision when selecting the ideal plastic material for your application.

What is polycarbonate?

Polycarbonate (PC) is a transparent, high-performance thermoplastic known for high impact resistance and good heat resistance. It transmits light at levels comparable to glass, which makes it suitable for applications that require transparency and toughness at the same time.

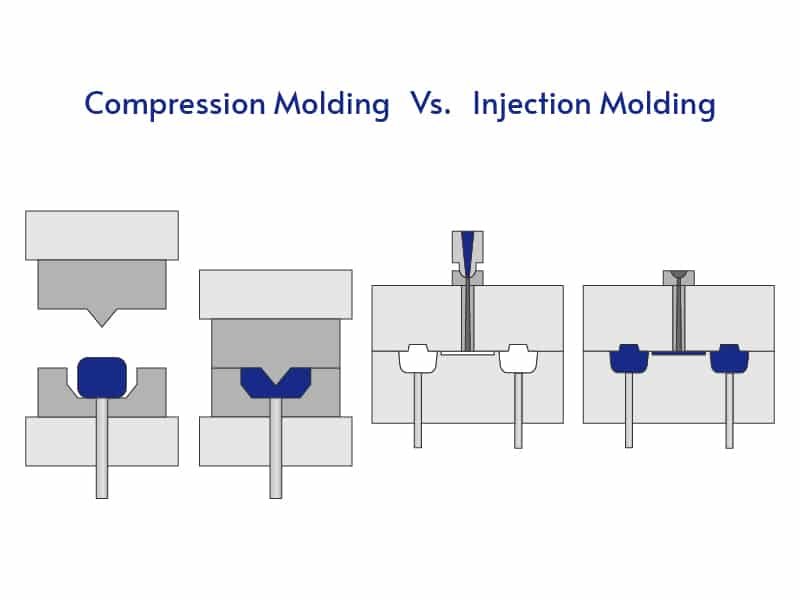

Common processing methods for polycarbonate include PC injection molding for lenses, housings, light covers, and precision parts. Extrusion into sheets and profiles for glazing, machine guards, and roofing panels. Blow molding for containers and specialty hollow parts.

Advantages of Polycarbonate

- High Impact Resistant: Polycarbonate has high impact strength, suitable for protective covers, eyewear, and safety shields.

- High Optical Clarity: Polycarbonate is known for its high light transmission and optical clarity, useful in lenses and transparent panels.

- High Dimensional Stability: Good dimensional stability and stiffness compared with many commodity plastics.

- Heat Resistance: Polycarbonate can withstand higher temperatures compared to many other plastics, including polypropylene.

Disadvantages of Polycarbonate

- Higher Material Cost: Polycarbonate tends to be more expensive than many common plastics, including polypropylene.

- Scratch Sensitivity: Polycarbonate can be prone to scratching. It often requires hard coatings for optical surfaces.

- UV Degradation: Polycarbonate is sensitive to UV without stabilizers or coatings, which can lead to yellowing over time.

- Sensitive to Chemicals: Polycarbonate has limited chemical resistance, especially to oils, solvents, and some organic acids.

What is polypropylene?

Polypropylene (PP) is a semi-crystalline thermoplastic characterized by low density, good chemical resistance, and attractive cost. It is common in both single-use and durable products, from packaging to automotive parts and piping.

Typical processing methods for polypropylene include PC injection molding for containers, caps, automotive interior parts, and household products. Extrusion for pipes, sheets, and profiles. Blow molding for bottles and tanks.

Advantages of Polypropylene

- Cost-Effective: Polypropylene is one of the least expensive plastics and is suitable for high-volume production.

- Chemical Resistance: PP is highly resistant to a variety of chemicals, including acids, bases, and solvents.

- Lightweight: Polypropylene is a lightweight material, which reduces part mass and material usage.

- Abrasion Resistance: Polypropylene has good abrasion resistance and low friction, makingit suitable for sliding and rotating components.

Disadvantages of Polypropylene

- Low Heat Resistance: Polypropylene has lower heat resistance than polycarbonate, limiting its use in high-temperature applications.

- Lower Impact Strength: PP is less impact-resistant than polycarbonate.

- Limited Transparency: Polypropylene is typically opaque, which limits its use in applications requiring optical clarity.

Polycarbonate vs Polypropylene: Key Differences

To better understand the differences between polypropylene and polycarbonate, here is a side-by-side comparison of their key properties:

| Property | Polycarbonate (PC) | Polypropylene (PP) |

|---|---|---|

| Impact Resistance | High (700-900 J/m) | Moderate (30-40 J/m) |

| Tensile Strength | 60-70 MPa (MegaPascal) | 30-40 MPa |

| Heat Resistance | High(130°C-140°C) | Low to Moderate (100°C-110°C) |

| Melting Point | ~ 267°C | 160°C - 170°C |

| Chemical Resistance | Moderate | High |

| Transparency | High (optical clarity) | Low (typically opaque) |

| Density | 1.20 g/cm³ | 0.90 g/cm³ |

| Flexural Modulus | 2.4 - 2.5 GPa (GigaPascal) | 1.3 - 1.5 GPa |

| Cost | Higher | Lower |

| UV Resistance | Poor (without UV coatings) | Good |

| Weight | Heavier | Lighter |

Cost comparison

In many projects, the choice comes down not only to performance but also to cost. Polypropylene is typically significantly cheaper than polycarbonate. It also processes efficiently in high-volume manufacturing, which reduces part cost further. When evaluating polypropylene vs. polycarbonate, cost-sensitive applications with moderate performance requirements often favor polypropylene, while safety-critical or optical applications can justify the premium for polycarbonate.

Environmental Impact

Polypropylene is a recyclable plastic, making it a more environmentally friendly option compared to polycarbonate, which can be more difficult to recycle. Additionally, the production of polycarbonate tends to have a larger environmental footprint due to the higher energy required for its processing.

That being said, polypropylene’s widespread use in packaging and disposable products has raised concerns about plastic waste. In contrast, polycarbonate’s applications often involve long-lasting products, potentially reducing the need for frequent replacements.

Applications of Polypropylene and Polycarbonate

Both polypropylene and polycarbonate are used across various industries, with each material excelling in different areas:

Polycarbonate Applications

- Automotive: Headlamp lenses, dashboard panels, and glazing.

- Electronics: Electrical enclosures and optical media.

- Medical: Medical devices, including syringes and IV components.

- Consumer Goods: Eyewear lenses, eyewash bottles, and protective covers.

Polypropylene Applications

- Packaging: Food packaging, containers, and plastic wraps.

- Automotive: Interior parts, battery casings, and under-the-hood components.

- Medical: Syringes, IV bags, and surgical instruments.

- Consumer Goods: Household products, textiles, and personal care items.

Conclusion

When choosing between polypropylene and polycarbonate, the decision ultimately depends on the specific needs of the application. Polycarbonate is ideal for products that require high impact resistance, heat resistance, and optical clarity, but it comes with a higher price tag and certain limitations regarding UV degradation. Polypropylene, on the other hand, is more cost-effective, offers excellent chemical resistance, and is lightweight, but its lower heat and impact resistance make it less suitable for high-stress applications.

If you need assistance in selecting the most suitable material for your project, Jiangzhi offers expert guidance and efficient batch production services to meet your specific needs.