POM injection molding service is a widely used process in modern manufacturing to produce high-precision, durable plastic parts. This article explores the POM material properties and the POM injection molding process.

What is POM?

POM, or polyoxymethylene, is a high-performance semi-crystalline thermoplastic derived from formaldehyde polymerization, often referred to as “plastic steel” for its strength and rigidity. With a density of 1.41–1.43 g/cm³, low moisture absorption (0.2–0.5%), and a melting point of 165–180°C, POM combines excellent tensile strength (60–75 MPa), hardness (Rockwell M85–94), and fatigue resistance. It comes in two main types: homopolymer, which offers higher crystallinity, superior strength, and stiffness but lower thermal stability, and copolymer, which provides better thermal and chemical resistance while minimizing center-line porosity in injection molding.

Advantages and Disadvantages of POM

Advantages of POM

- High strength and rigidity

- Low-friction, self-lubricating

- Fatigue and creep resistance

- Dimensional stability (low water absorption)

- Chemical and corrosion resistance

- FDA-compliant food safety grades

- Good thermal resistance (~100–105°C, higher for copolymers)

Disadvantages of POM

- High shrinkage, sensitive to molding conditions

- Thermal decomposition risk during processing

- Reacts with copper/alloys

- Limited UV resistance without stabilizers

- Potential mold corrosion in the molten state

- Flammable without additives

POM Injection Molding Process Conditions

POM Injection Molding Process Conditions

- Material Preparation: POM resin should be thoroughly dried before molding to remove trace moisture. This prevents bubbling, surface blemishes, and polymer degradation during melting.

- Melt and Mold Temperatures: The melt is processed at moderately high temperatures for proper flow, while the mold is kept at a medium range to control shrinkage and reduce residual stress in the finished parts.

- Injection Speed and Pressure: Medium-to-high injection speed and pressure are typically used, ensuring the molten resin fills complex mold cavities completely and compensates for natural material shrinkage.

- Cooling and Ejection: Because POM crystallizes quickly, carefully managed cooling helps prevent warping or distortion. Its natural lubricity allows easy ejection with minimal draft angles, reducing cycle times.

- Avoidance of Copper Components: Copper and its alloys can catalyze POM degradation, so stainless steel or treated mold components are preferred to extend mold life and maintain product quality.

Benefits of POM Injection Molding

The process of POM injection molding offers several advantages over alternative manufacturing methods:

Precision and Complexity

POM injection molding produces molded electronics parts with intricate geometries and tight tolerances, thanks to POM’s excellent flow properties.

Cost-Effectiveness

The process is highly automated, reducing labor costs and enabling high-volume production of pom plastic injection molding parts. Minimal secondary processing saves time and money.

Durability and Performance

POM’s fatigue resistance and strength ensure long-lasting parts, ideal for acetal injection molding of high-performance components. Its self-lubricating nature eliminates additional coatings.

Lightweight Metal Replacement

Polyoxymethylene injection molding creates lightweight, strong alternatives to metal, reducing weight by up to 50% while maintaining structural integrity. This lowers material and assembly costs.

Chemical and Environmental Resistance

POM resists fuels, solvents, and mild acids, making it suitable for harsh environments in pom injection applications. FDA-compliant grades support food and medical uses.

POM Injection Molding Design Guide

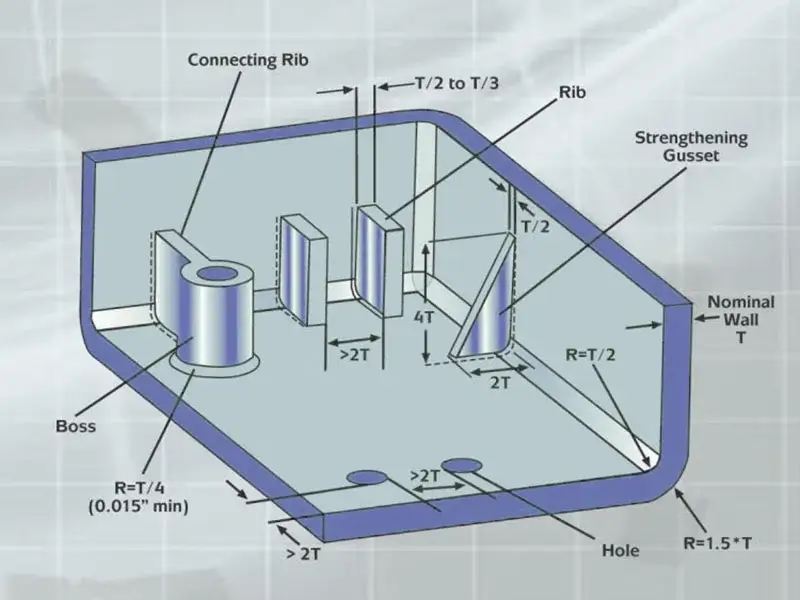

Designing for POM injection molding demands attention to detail to avoid pitfalls.

- Uniform wall thickness is non-negotiable. Variations over 15% cause uneven cooling and warpage in acetal injection molding. Thicker sections cool more slowly, leading to sinks.

- Draft Angles: Thanks to POM’s lubricity, draft angles can be minimal, usually between 0.5° and 1°. Zero draft may be acceptable for certain functional parts like gears.

- Radii and Corner Design: Radii at corners should be at least 25% of wall thickness to reduce stress concentrations in Delrin injection molding—sharp edges crack under load.

- Gate design matters: use pinpoint or edge gates with diameters 0.5-0.6 times wall thickness for minimal vestige. Position gates away from high-stress areas to prevent weak-knit lines in polyoxymethylene injection molding.

- Compensate for Shrinkage: Designs should anticipate POM’s shrink rates of 1.9–3.5% (depending on grade) to maintain dimensional accuracy.

- Design with ribs (half wall thickness) for stiffness without adding mass.

- Venting design is important; poor vents trap gases, causing burns.

Industrial Applications of POM Injection Molding

POM injection molding powers diverse industries. Its strength applies widely.

- Automotive: fuel systems, gears, seat adjusters, think valves, pumps.

- Medical: syringes, surgical tools, pacemakers.

- Industrial: valves, bearings, conveyor parts.

- Consumer: zippers, fasteners, shower heads.

- Electronics: switches, connectors.

Conclusion

Partnering with Jiangzhi, an experienced manufacturer, ensures precise mold design, optimized processing parameters, and strict quality control. For high-quality POM injection molding services, contact Jiangzhi today for reliable solutions.