PP injection moulding transforms a versatile thermoplastic into precise, cost-effective components for industries ranging from automotive to consumer goods. PP molded parts are known for their lightweight nature and robust properties. This guide explores the PP injection moulding process in detail, highlighting why polypropylene is a preferred material, the steps involved in injection molding PP, common challenges, design guidelines, and its applications.

What is Polypropylene?

Polypropylene, a semi-crystalline thermoplastic polymer derived from propylene monomers (C3H6)n, is prized for its unique molecular structure, blending ordered crystalline regions with amorphous flexibility. This composition yields a low density (0.895–0.92 g/cm³), high flexural strength, and excellent flow properties, making it ideal for plastic injection molding. Available in homopolymer (stiffer, higher melting point) and copolymer (more flexible, impact-resistant) forms, PP caters to diverse needs, from rigid automotive components to pliable living hinges.

Why PP Injection Moulding?

The polypropylene injection molding process is favored for its efficiency and cost-effectiveness. PP’s low melt viscosity ensures rapid mold filling, reducing cycle times and production costs. Its recyclability aligns with sustainability goals, while its compliance with regulations like FDA and REACH makes it suitable for food and medical applications. Compared to alternatives like ABS or nylon, PP injection moulding offers a compelling balance of performance and affordability, driving its widespread adoption in high-volume manufacturing.

Advantages and Limitations of Polypropylene

The appeal of PP plastic injection molding lies in its robust properties, though it comes with certain trade-offs that require careful consideration.

Advantages of Polypropylene

- Cost-Effective: PP is one of the most affordable thermoplastics, slashing material and production costs in injection moulding PP applications.

- Easy processing: PP can be molded using standard injection molding equipment without major modifications.

- Lightweight: Its low density reduces component weight, enhancing fuel efficiency in automotive parts and lowering shipping costs for consumer goods.

- Excellent moisture resistance: PP does not absorb water easily, which helps maintain dimensional stability.

- Chemical Resistance: PP withstands acids, alkalis, and organic solvents, making it ideal for containers, medical devices, and chemical storage.

- High impact resistance: Especially in copolymer grades, PP can absorb shocks without cracking.

- Fatigue Resistance: Exceptional durability in repeated flexing, as seen in living hinges like bottle caps, sets PP apart.

- Low Friction: A slippery surface suits low-friction applications, such as gears or furniture contact points.

- Recyclability: As a thermoplastic, PP can be remelted and reused, supporting eco-friendly manufacturing.

Limitations of Polypropylene

- Poor Bonding: Low surface energy complicates gluing or painting, often necessitating welding or surface treatments like plasma activation.

- UV Sensitivity: Without stabilizers, PP degrades under UV exposure, limiting outdoor applications unless additives are used.

- Flammability: Highly flammable without flame-retardant additives, restricting use in fire-sensitive environments.

- Shrinkage: PP exhibits 1–3% shrinkage, potentially causing dimensional inaccuracies if not addressed through design or additives.

- Chemical Sensitivity: Aromatics and chlorinated solvents can swell or soften PP, requiring careful material selection.

Overview of the Polypropylene Injection Molding Process

The PP injection molding service process transforms raw polypropylene pellets into finished parts through a series of controlled steps:

1. Material Preparation

PP pellets are dried at 80–90°C for 2–4 hours to reduce moisture content below 0.1%, preventing defects like bubbles or surface imperfections.

2. Melting

The pellets are heated inside the barrel to a molten state. Optimal barrel temperatures range between 400°F and 570°F (approximately 200°C to 300°C).

3. Injection

Molten PP is injected into the mold at pressures of 68.6–137.2 MPa.

4. Pressure Holding

After filling, holding pressure compensates for material shrinkage during cooling, maintaining cavity pressure to avoid sink marks and voids.

5. Cooling

The molten PP solidifies as it cools inside the mold. Cooling time and mold temperature (generally between 50°C and 90°C) must be optimized to ensure dimensional accuracy and minimize warpage.

6. Ejection

Once cooled, the mold opens, and ejector pins push the finished part out. Proper ejection mechanisms prevent deformation or damage.

7. Post-Processing

Optional finishing steps, such as trimming, surface treatment, or decoration, may follow to enhance functionality or aesthetics.

Common Defects and Prevention Strategies

Despite its advantages, injection molding polypropylene plastic can encounter defects that compromise quality. Below are common issues and actionable solutions:

- Warping: Distortion from uneven cooling or high shrinkage (1–3%). Maintain uniform wall thickness (0.635–5 mm), optimize mold temperature (50°C), and use balanced cooling channels. Adding 20–30% glass fiber reduces shrinkage to ~0.7%.

- Short Shots: Incomplete mold filling due to insufficient pressure, small gates, or low temperatures. Increase injection pressure, raise melt temperature (220–280°C), enlarge gate size (50% of wall thickness), and improve venting to release trapped air.

- Flash: Excess material leakage from high pressure or worn molds. Reduce injection speed, enhance clamping force, and maintain tight mold tolerances (0.01–0.03 mm). Regular mold maintenance prevents wear-related flash.

- Sink Marks: Depressions from uneven cooling in thick sections. Increase holding pressure, extend cooling time, and place gates near thicker areas to ensure proper packing. Thin, uniform walls minimize this risk.

- Flow Marks: Visible streaks from inconsistent flow or low temperatures. Adjust melt temperature, optimize injection speed, and balance runner systems to ensure uniform material distribution.

Design Guidelines for PP Molded Parts

Designing parts for polypropylene injection molding requires precision to maximize PP’s strengths and minimize defects. Key guidelines include:

- Uniform Wall Thickness: Maintain 0.635–5 mm to ensure even flow and cooling, reducing warping and sink marks. Gradual transitions between thick and thin sections prevent stress concentrations.

- Use ribs and bosses: Reinforce parts with ribs (preferably 50-60% of wall thickness) to increase strength without adding bulk.

- Avoid thick sections: Thick areas can cause bubbles and sink marks; Reinforce parts with ribs (preferably 50-60% of wall thickness) to increase strength without adding bulk.

- Draft Angles: Apply 0.5–1° for smooth surfaces, 1–5° for textured surfaces, and up to 10° for filled PP to facilitate ejection. Proper angles prevent surface scratches or ejection issues.

- Radii and Fillets: Use radii (25–75% of wall thickness, minimum 0.3 mm) at corners to enhance flow, reduce stress, and improve durability. For living hinges, aim for 0.5–1 mm thickness to balance flexibility and strength.

- Runner and Gate Design: Employ full-round runners (4–7 mm diameter) and gates (pin gates: 0.7–1.5 mm; edge gates: 50% depth, twice the width of wall thickness) to optimize flow and minimize shear stress. Position gates at thick sections to avoid stagnation.

- Venting: Include vent holes (0.025–0.038 mm deep) to release trapped air, preventing burn marks or incomplete filling. Proper venting is critical for complex geometries.

- Minimize Undercuts: Avoid complex undercuts to simplify mold design and reduce costs. Use sliders or lifters sparingly, ensuring cost-effective production.

Applications of Polypropylene Injection Molded Parts

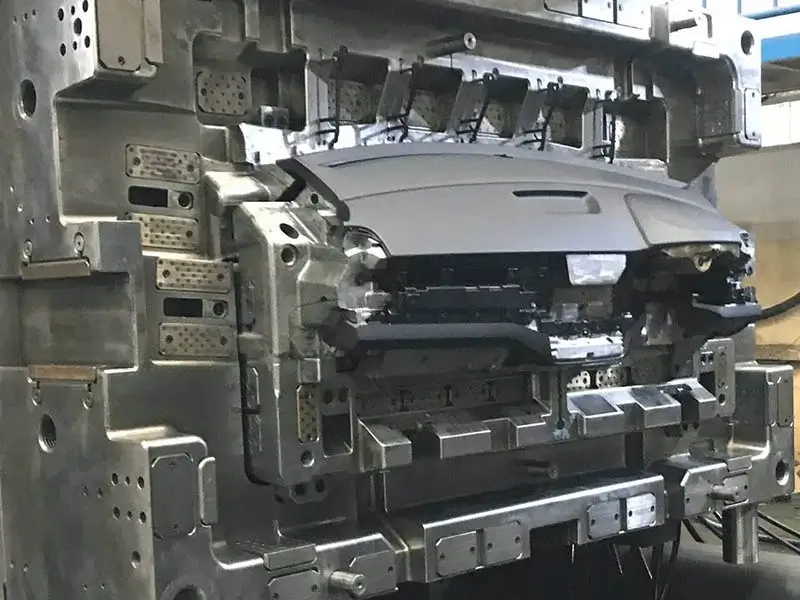

Polypropylene injection molded parts are widely used across industries for their lightweight strength, chemical resistance, and cost-effectiveness. As custom plastic components, PP is ideal for automotive parts such as bumpers, dashboards, and battery housings, providing durability without extra weight. Its food-safe and moldable properties suit packaging applications, including containers, caps, and films. In medical devices, PP is used for syringes and labware due to its resistance to sterilization. Consumer products like toys, storage solutions, and kitchenware benefit from PP’s toughness and versatility, including flexible, fatigue-resistant living hinges for flip-top lids and cosmetic containers.

Collaborating with Jiangzhi

Mastering the PP plastic injection molding process requires a deep understanding of material behavior, process parameters, and design considerations. Partnering with experienced polypropylene injection molding experts can significantly enhance product quality, reduce defects, and optimize production efficiency. Jiangzhi is a professional OEM manufacturer and supplies one-stop PP injection moulding solutions. Welcome to contact Jiangzhi experts today.