In the realm of engineering materials, PTFE is popular as a powerhouse due to its unparalleled chemical resistance and low-friction properties. Commonly known as Teflon, this fluoropolymer has revolutionized industries requiring durable, high-performance components. PTFE CNC machining emerges as a pivotal method for fabricating PTFE parts, offering precision and versatility in shaping this unique material. By leveraging computer numerical control (CNC) technology, manufacturers can create intricate designs that meet stringent specifications.

What is PTFE (Teflon)?

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer derived from tetrafluoroethylene monomers. Discovered accidentally in 1938 by DuPont chemist Roy Plunkett, it was branded as Teflon. PTFE is widely used in applications where chemical resistance and non-stick properties are critical. It’s known for its excellent dielectric properties, making it ideal for use in electronic components. Additionally, its ability to resist extreme temperatures—from -200°C to +260°C—makes PTFE highly suitable for both low and high-temperature applications.

Why Choose CNC Machining for PTFE?

Traditional fabrication techniques like injection molding can degrade PTFE due to its high melting point and sensitivity to heat. In contrast, PTFE CNC involves direct cutting from solid stock, such as rods or sheets, preserving the material’s integrity. This makes PTFE CNC ideal for prototypes, small batches, and complex geometries where precision is paramount. Variants like filled PTFE (e.g., with glass or carbon fibers) further enhance its machinability, allowing tailored properties without compromising the core benefits of machining Teflon.

PTFE Material Characteristics

Before delving into the CNC machining process, it’s essential to understand the material characteristics.

- Chemical Resistance: PTFE is incredibly resistant to most chemicals; it resists almost all acids, bases, and solvents, even at elevated temperatures, making it a go-to material for applications in corrosive environments.

- Low Friction: PTFE has a very low coefficient of friction, which makes it ideal for moving parts, reducing wear and tear.

- Thermal Stability: PTFE can withstand a wide range of temperatures( -200°C to 260°C), making it perfect for high-temperature applications.

- Electrical Insulation: PTFE’s excellent dielectric properties make it a superior material for electrical insulation in sensitive electronic devices.

CNC Machining Process for PTFE

The process of machining Teflon involves several critical steps to ensure the material’s integrity and precision. However, PTFE is a soft material that can easily deform under pressure, so specific precautions are necessary during CNC machining.

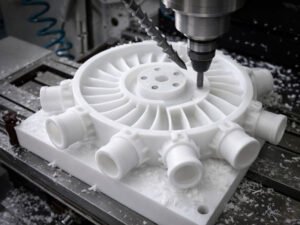

PTFE Milling

Milling is one of the most common techniques for PTFE CNC machining. It uses rotary cutters to remove material and create the desired shape. The low-friction nature of PTFE makes it ideal for milling, but care must be taken to prevent material deformation due to excessive heat.

PTFE Turning

For cylindrical components, Teflon CNC machining using turning methods is widely employed. The material is shaped as it rotates on a lathe, and tools are applied to remove material layer by layer.

PTFE Drilling and Routing

PTFE is drilled and routed using high-speed tools designed to handle its soft yet abrasive nature. The key challenge in machining Teflon is to maintain the integrity of the part without causing overheating, which can lead to warping.

Core Advantages of PTFE CNC Machining

The advantages of PTFE CNC machining services are multifaceted, positioning it as a superior choice over alternatives.

- The first is machinability. PTFE cuts effortlessly, yielding mirror-like finishes without secondary polishing, which saves time and costs.

- Precision is another benefit. CNC controls achieve tolerances as tight as ±0.13 mm, making them ideal for intricate parts.

- Teflon CNC machining avoids thermal degradation, compared to other methods. thereby preserving the chemical purity and performance of PTFE.

- It’s versatile for low-volume production, enabling rapid prototyping without expensive molds.

- Self-lubricating properties reduce the need for additional coatings, enhancing part longevity in frictional applications.

Challenges in PTFE CNC Machining

While CNC machining PTFE offers numerous benefits, there are several challenges that must be addressed to ensure high-quality results:

- Deformation: PTFE is a soft material, and excessive heat generated during machining can cause deformation. To mitigate this, it’s crucial to use appropriate feed rates, cutting speeds, and cooling methods.

- Tool Wear: PTFE is abrasive and can cause rapid wear on cutting tools. Regular tool maintenance or the use of specialized tools is necessary to maintain efficiency and precision.

- Dust and Fumes: Machining Teflon produces fine dust and fumes, which can be harmful if not properly ventilated.

Optimization Tips for PTFE Design and Machining

To ensure efficient and high-quality PTFE CNC machining, it’s important to design parts with machinability in mind. Here are some key optimization tips:

- Wall thickness: Keep ≥1.5 mm (better ≥2 mm). Thin walls (<1 mm) easily bend, vibrate, warp, or creep.

- Fillets / rounded corners: Use a minimum 1.0–1.5 mm radius on all internal and external corners. Sharp corners cause burrs, tearing, and stress cracks.

- Avoid deep & thin features: Depth should not exceed 4× wall thickness. Deep pockets, long ribs, or slender parts vibrate and distort easily.

- Thermal expansion: PTFE expands ~10× more than metal. Oversize critical dimensions by 0.3–0.6% if the part works in a wide temperature range.

- Symmetry: Prefer balanced, symmetrical shapes. Very asymmetric parts (thin, large disks, one-sided deep cuts) warp easily from uneven heat.

- Choose filled PTFE when needed: For better strength, less creep, or tighter tolerances — use glass-filled, carbon-filled, or bronze-filled grades.

Applications of PTFE CNC Machining

PTFE’s versatility makes it suitable for a wide range of applications across various industries.

Automotive Industry: PTFE seals, bearings, and gaskets that can withstand high temperatures and harsh environments.

Medical Industry: PTFE implants, tubing, and surgical instruments.

Electronics Industry: PTFE electrical components, capacitors, and connectors.

Aerospace Industry: PTFE aerospace components.

Conclusion

PTFE processing encompasses various techniques, from injection molding for mass production to extrusion for tubes and compression molding for basic shapes. Among these, PTFE CNC machining stands as a versatile staple, excelling in customization and precision. For specialized needs, Jiangzhi offers expert PTFE CNC services, from design consultation to finished parts.