PVC injection molding service is a popular manufacturing technology that creates thousands of components from automotive parts to medical devices. This article explores the basics of PVC injection molding, PVC material properties, and the molding process.

What is PVC Injection Molding?

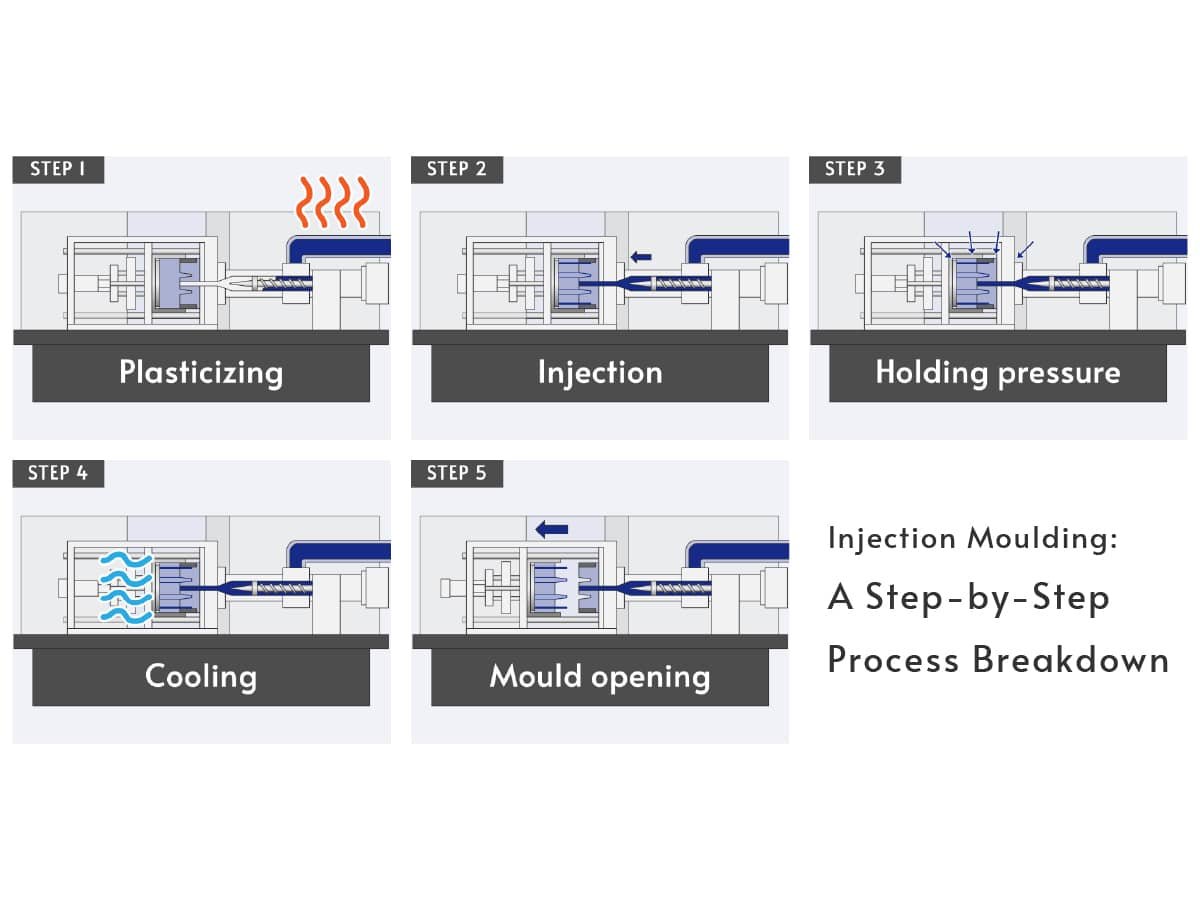

PVC injection molding is a process in which melted polyvinyl chloride is injected into molds under high pressure to form precise and complex shapes. The process begins with heating PVC pellets or powder until they liquefy. The molten material is then injected into temperature-controlled molds, where it cools and solidifies into the desired part. After cooling, the molded component is ejected from the mold, completing one production cycle. This process allows for high-volume mass production with excellent repeatability and tight tolerances.

PVC injection molding differs from other molding techniques in its sensitivity to temperature and shear forces, necessitating precise control throughout to prevent degradation and maintain product quality.

Why Choose PVC Plastic as an Injection Molding Material?

The choice of PVC for injection molding stems from its unique beneficial properties. PVC exists in two main forms: rigid and flexible. Rigid PVC is dense, hard, and impact-resistant, ideal for robust structural parts such as pipes, window profiles, and automotive components. Flexible PVC incorporates plasticizers to add elasticity, making it suitable for cables, medical tubing, and hoses.

PVC’s tensile strength (40–60 MPa) ensures robust parts, while its low moisture absorption (<0.2%) guarantees stability in humid environments. Additionally, PVC’s chemical resistance is excellent; it withstands acids, bases, salts, oils, and various chemicals without degradation, making it well-suited for harsh environments. Its flame-retardant properties and self-extinguishing nature add a critical safety dimension, especially in electrical and construction applications. Cost-effectiveness is another major advantage. PVC is available at relatively low prices compared to specialty thermoplastics and can be processed in large volumes economically.

PVC Injection Molding Process Guide

Understanding the PVC injection molding process steps and parameters is crucial for optimizing outcomes and avoiding defects. Below is a detailed guide to the PVC injection molding process.

1. Material Preparation and Drying

PVC pellets absorb minimal moisture, but drying them at 75–90°C for 1.5 to 2.5 hours helps avoid defects. Additives like stabilizers, plasticizers, lubricants, and fillers are mixed in to enhance properties and processing performance.

2. Heating and Plasticization

The PVC is fed into the injection molding machine’s barrel. Heat the material to 345°F–375°F, ensuring it reaches a uniform molten state without degrading.

3. Injection

Inject the molten PVC into a mold using a conical nozzle (6mm diameter, 5° angle) under high pressure. Control injection speed to avoid turbulence, which can cause air entrapment.

4. Cooling and Solidification

Cool the mold at 70°F–130°F to solidify the part.

5. Ejection

Eject the solidified part using draft angles (0.5°–1°) to facilitate smooth release. Proper venting (0.03–0.05 mm) minimizes air traps and flash.

6. Post-Processing

Post-processing may include trimming excess material, decorating, or additional finishing.

Challenges and Solutions

PVC’s heat sensitivity is a primary challenge in the PVC moulding process. Overheating above 390°F (200°C) can lead to thermal degradation, releasing harmful gases like HCl, which poses risks to operators and equipment. To mitigate this, use precise temperature controls and corrosion-resistant molds (stainless steel or chrome-plated). A poorly maintained machine can prevent issues, so regular checks of screw geometry, nozzle condition, and barrel cleanliness are essential. Optimize injection speed and pressure to avoid shear stress, and ensure proper venting to prevent defects like flash or short shots.

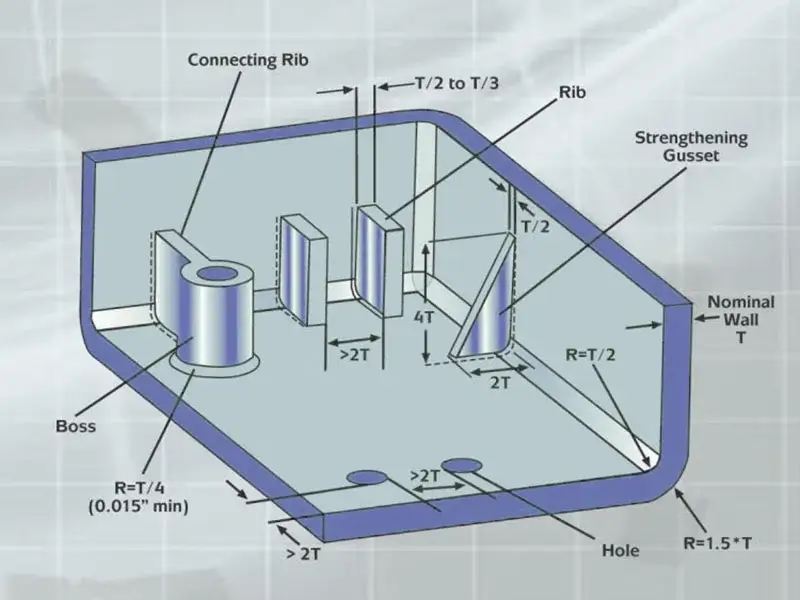

PVC Injection Molding Design Guidelines

Designing for PVC injection molding requires careful attention to geometry and mold specifications to ensure defect-free parts. Here are key guidelines to optimize your designs:

- Wall Thickness: Maintain uniform wall thickness to ensure consistent cooling and shrinkage. Uneven walls can cause warping or sink marks. For transitions, limit thickness changes to 10–15% of the nominal thickness.

- Draft Angles: Vertical walls should have draft angles of 0.5° to 1° to facilitate easy ejection from the mold. Longer parts may require slightly larger angles to prevent sticking.

- Radii and Fillets: Apply radii of 25–75% of wall thickness to corners to reduce stress concentrations. Sharp corners can lead to cracks or weak points.

- Gate Design: Use appropriate gates (needle, submarine, fan gates) according to part size to optimize flow and minimize material waste. Position gates away from critical areas to avoid visible marks.

- Venting: Include vents to allow air to escape during injection, preventing burn marks or voids.

- Shrinkage Allowance: Account for PVC’s relatively low shrinkage by adjusting mold dimensions accordingly.

- Mold Material: Opt for stainless steel or chrome-plated molds to withstand PVC’s corrosive properties. This ensures mold longevity and part quality.

Advantages and Disadvantages of PVC Injection Molding

Advantages of PVC Injection Molding

Cost-Effectiveness: PVC’s low material cost and minimal waste make it economical for high-volume production. Economies of scale further reduce per-unit costs.

Versatile Finishing: PVC supports finishes like mirror polish, texturing, or engraving, enhancing aesthetic appeal for consumer goods.

Material Versatility: Customizable rigid or flexible formulations for varied applications.

Disadvantages of PVC Injection Molding

Low Heat Resistance: PVC degrades at temperatures above 60°C–82°C, limiting its use in high-temperature environments like automotive under-hood components.

Harmful Gas Release: Overheating during the PVC moulding process can release hydrochloric acid or dioxins, requiring stringent safety protocols.

High Tooling Costs: Initial mold fabrication is high, with lead times of 5–12 weeks, posing barriers for low-volume projects.

Environmental Concerns: While recyclable, PVC is not biodegradable, creating disposal challenges if not properly managed.

Applications of PVC Injection Molding

The PVC moulding process supports diverse industries:

- Automotive: Door panels, dashboards, weather seals, under-hood components.

- Construction: Pipes, window frames, gutters, fittings.

- Medical: Tubing, catheters, masks, disposable medical devices (with biocompatible formulations).

- Electrical/Electronics: Cable insulation, connectors, switch housings.

- Consumer Goods: Toys, storage containers, household equipment.

- Packaging: Bottle caps, cosmetic containers, tamper-evident seals.

Conclusion

Jiangzhi, as an injection molding manufacturer, offers comprehensive expertise and advanced capabilities to deliver high-quality molded parts tailored to exact specifications. Welcome to contact Jiangzhi and get professional PVC injection molding service.