Rubber overmolding is a versatile and increasingly popular manufacturing process that combines the unique properties of rubber with other substrates such as plastic or metal to create durable, high-performance products. This process involves molding rubber over a pre-existing component, resulting in parts that benefit from the strength and rigidity of the substrate and the flexibility, grip, and protective qualities of rubber. As an experienced injection molding manufacturer, we recognize the growing demand for rubber overmolding in precision applications.

In this article, we will explore what rubber overmolding is, how the rubber overmolding process works, common material combinations like silicone rubber overmolding, the main advantages of rubber overmolding, design considerations, and typical applications across industries.

What is Rubber Overmolding?

Rubber overmolding is a manufacturing process that bonds a layer of rubber to rigid substrates, such as metals or plastics, to combine flexibility with structural strength. By integrating rubber’s elasticity with a substrate’s rigidity, rubber molding creates parts that offer enhanced grip, sealing, or insulation. This technique, often referred to as rubber insert molding when embedding inserts, produces components that are both functional and durable, reducing the need for separate assembly steps. For more best practices, check out our comprehensive overmolding guide.

The process encompasses three primary types, each suited to specific applications:

- Injection Overmolding: Molten rubber is injected into a mold containing the substrate, ensuring tight bonds. Delivers high precision for complex geometries, ideal for automotive seals or medical grips.

- Compression Overmolding: Rubber is placed over the substrate and compressed under heat, suitable for tool handles. Cost-effective for low-volume production, using simpler molds.

- Transfer Overmolding: Transfers rubber into a mold cavity via a pot-and-plunger system, perfect for intricate designs like electronic seals.

How the Rubber Overmolding Process Works?

Rubber overmolding involves three key stages: substrate preparation, molding, and curing.

Substrate Preparation: The base material (plastic or metal) is cleaned and treated to ensure strong adhesion. Metals may require degreasing and primers; plastics benefit from surface treatments or compatible resins.

Molding: The treated substrate is placed into a mold. Rubber is applied via injection, transfer, or compression molding, depending on the design and material requirements.

Curing and Cooling: Under heat and pressure, the rubber cures and bonds to the substrate. Once solidified, the part is removed, trimmed, and inspected.

Post-Processing: Final steps include flash removal, edge deburring, and quality checks to ensure adhesion and surface finish meet specifications.

Common Substrate and Rubber Material Combinations

Rubber overmolding leverages a variety of rubbers and substrates, each chosen for specific properties and compatibility. Below are common combinations used in rubber molding:

Rubber Materials:

- Silicone: Heat-resistant (up to 250°C), flexible, and biocompatible, ideal for silicone rubber overmolding in medical devices and electronics.

- EPDM: Weather-resistant, withstands UV and ozone, perfect for outdoor automotive seals.

- Nitrile (NBR): Oil-resistant, durable for fuel system components in overmolding rubber to metal.

- TPU: Highly elastic, bonds well to plastics like ABS, and is used in consumer electronics.

- Natural Rubber: Cost-effective, with excellent elasticity, suited for tool grips.

Substrates:

- Metals: Stainless steel, aluminum, and brass, often used in industrial or automotive parts, require primers or sandblasting for adhesion in overmolding rubber to metal.

- Plastics: ABS, polycarbonate (PC), nylon, and polypropylene (PP), common in consumer goods, bond well with TPU or TPE in overmolding rubber to plastic.

Key Advantages of Rubber Overmolding

Rubber overmolding service delivers a range of benefits that enhance product functionality and user experience.

Enhanced Ergonomic Grip

Rubber’s soft, non-slip surface transforms rigid substrates into user-friendly parts. In rubber insert molding, silicone or TPU overmolded onto tool handles or medical grips ensures comfort and control, reducing fatigue during prolonged use.

Superior Durability

The rubber layer absorbs vibrations and reduces noise, enhancing user comfort and product longevity in machinery and power tools.

Effective Vibration Damping

Rubber absorbs shock and reduces noise, ideal for overmolding rubber to plastic in automotive gearshift knobs or industrial mounts. EPDM or silicone overmolding minimizes vibrations, enhancing user comfort and equipment longevity in dynamic applications.

Reliable Waterproofing and Sealing

Rubber overmolding creates tight seals that protect against moisture, dust, and contaminants, critical for electronics, medical devices, and automotive parts.

Electrical and Thermal Insulation

Silicone-overmolded connectors in electronics provide excellent insulation, safeguarding against electrical currents and heat.

Aesthetic and Functional Appeal

Rubber offers soft-touch or colored finishes, enhancing product aesthetics. TPU-overmolded phone cases in overmolding rubber to plastic combine visual appeal with impact resistance, elevating user experience in consumer goods.

Cost-Effective Manufacturing

By integrating multiple functions into a single part, rubber overmolding reduces assembly costs. Compression overmolding, in particular, is economical for low-volume production, streamlining manufacturing for tool grips or industrial fittings.

Design Considerations for Rubber Overmolding

Successful rubber overmolding requires careful design and material selection to ensure product quality and performance:

Material Compatibility: Selecting rubber and substrate materials with compatible thermal and chemical properties is crucial to achieving a strong bond and preventing delamination.

Surface Treatment: Proper cleaning and surface preparation of the substrate enhances adhesion. For metals, primers or adhesives may be required.

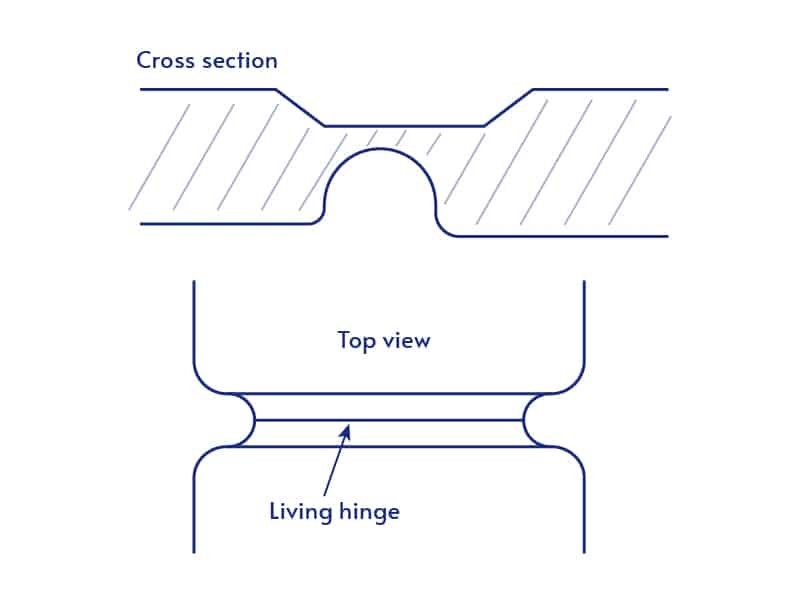

Mold Design: The mold must accommodate both materials’ flow characteristics and curing requirements. Considerations include draft angles for easy demolding, uniform wall thickness to prevent warping, and venting to avoid air entrapment.

Dimensional Tolerances: Rubber materials typically shrink during curing; designers must account for this to maintain precise dimensions.

Complexity and Undercuts: Overly complex geometries or undercuts can complicate molding and demolding, increasing costs and defect rates.

Rubber Hardness and Thickness: Choosing appropriate rubber hardness (durometer) and thickness affects flexibility, grip, and durability.

Draft Angles: Incorporate taper geometry with draft angles of 2–5° to facilitate demolding, reducing stress on the rubbe,r and preventing tearing during ejection. For overmolding rubber to plastic with textured surfaces, increase angles by 1° per 0.025 mm of texture depth to avoid sticking.

Environmental Conditions: Consider exposure to temperature extremes, chemicals, UV light, and wear when selecting materials and designing parts.

Typical Applications of Rubber Overmolding

Rubber overmolding finds use in diverse industries due to its ability to enhance product functionality and aesthetics:

Automotive: Overmolded rubber grips on steering wheels, shift knobs, door handles, seals, and vibration-dampening components.

Medical Devices: Silicone rubber overmolding provides ergonomic, hygienic handles and seals for surgical instruments, diagnostic equipment, and wearable devices.

Consumer Electronics: Soft-touch buttons, protective cases, and waterproof seals in smartphones or wearables.

Industrial: Vibration-damping mounts, tool handles, control panels, machinery grips, conveyor belts, and corrosion-resistant fittings.

Aerospace: Overmolded seals, gaskets, and cockpit controls.

Sports and Recreation: Rubber overmolded grips for golf clubs, tennis rackets, bicycle handles, and fitness equipment.

Military and Defense: Firearm grips, tactical gear, and vehicle components.

Food Processing: Silicone rubber overmolding ensures food-safe seals and components resistant to harsh cleaning chemicals and temperatures.

Conclusion

Rubber overmolding effectively integrates rubber with plastic or metal substrates to deliver products with superior durability, grip, sealing, and vibration resistance. Whether you’re exploring silicone overmolding or need custom rubber-overmolded parts, choosing the right rubber parts manufacturer is key. Jiangzhi, a trusted rubber parts manufacturer with rich experience and global collaboration, offers tailored rubber overmolding solutions to meet your exact needs. Contact us today to see how we can support your next project.