Stress whitening and stress marks are common defects in injection molding that affect the appearance and structural performance of plastic products. These issues often occur in materials such as ABS, PP, and PC, resulting in visible surface flaws that can compromise product quality. As a supplier with extensive experience in injection molding, we assist customers in understanding stress mark injection molding defects from a product perspective. This includes their causes, impacts, and prevention methods.

What Are Stress Marks in Injection Molding?

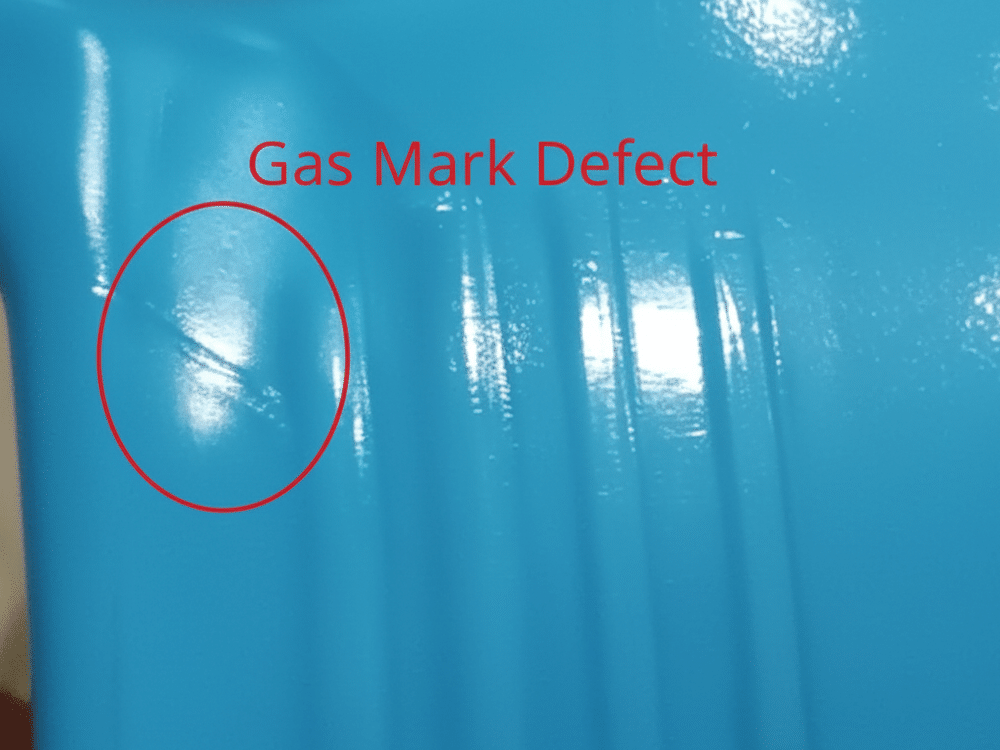

Stress marks in injection molding refer to visible defects that appear on or near the surface of plastic parts. They manifest as whitish or translucent lines, streaks, or spots and are often caused by internal stresses generated during the molding process. These marks are commonly found around critical areas such as ejector pin locations, parting lines, gate regions, and thick-to-thin wall transitions. Although stress marks may seem superficial, they often indicate underlying material deformation that can lead to mechanical weaknesses, such as cracking or warping.

Stress Whitening vs. Stress Marks

Stress whitening is closely related but slightly different from stress marks. Stress whitening refers to a milky or opaque discoloration caused by the formation of micro-voids or crazes in the material under tensile stress. In contrast, stress marks are more about surface lines from frozen stresses during flow and cooling. However, the two can overlap in injection molding. For example, high injection pressures can induce both whitening from void formation and marks from orientation stresses near gates. In practice, stress whitening may precede or accompany stress marks in areas of high strain, such as around inserts.

Common Stress-Related Defects in Molded Parts

Stress in injection molding leads to several defects beyond surface marks, affecting part quality and performance. The following sections detail key defects caused by stress.

Sink Marks Caused by Stress

One common defect is sink marks, which are depressions on the surface caused by uneven shrinkage in thicker sections. They occur when the core material cools more slowly than the surface, pulling inward. Sink marks are frequent in parts with ribs or bosses, reducing aesthetic quality and potentially weakening the structure. Sink marks often lead to assembly difficulties and require additional finishing, increasing costs.

Warpage Caused by Stress

Warpage is another defect, where the part distorts due to asymmetric cooling or stress imbalances. It happens in long, thin components or those with uneven wall thicknesses, causing bends or twists. Warpage can lead to dimensional inaccuracies exceeding 0.5mm, making parts unfit for tight tolerances in applications like electronics enclosures.

Cracking Caused by Stress

Cracking results from high residual stresses combined with external loads or environmental factors. It appears as fine lines or fractures, often starting at stress concentration points like sharp corners. Cracks can propagate over time, leading to premature failure and safety risks in load-bearing parts. Chemical exposure or recycled materials with degraded properties exacerbate this, shortening product life.

Premature Failure Caused by Stress

Premature failure refers to the early breakdown of molded parts under normal conditions, driven by accumulated stress that leads to brittleness or fatigue. This defect arises from factors like poor mold design or stiff materials, causing micro-cracks to spread over time. High-load areas in the part are most affected, resulting in fractures or corrosion.

How to Avoid Stress Marks on Injection Molded Parts?

Preventing stress mark injection molding requires a systematic approach involving material selection, design, process parameters, and mold optimization.

Material Selection

Use materials with low thermal expansion, like PP or ABS, instead of PC to reduce stress risk. High molecular weight resins and glass fiber reinforcement improve strength and minimize internal stress, while impurities should be avoided as they act as stress points.

Process Parameter Control

Proper temperature, pressure, and cooling are key. Higher melt and mold temperatures ensure smooth flow and uniform cooling, moderate injection pressure avoids shear near gates, and shorter holding times with extended cooling stabilize the part and reduce stress marks.

Product Design

Optimize molded parts design. Keep wall thickness consistent, transitions smooth, and add generous fillets to spread stress. Match insert expansion rates with the resin and use round or elliptical holes to prevent stress buildup at weak points.

Mold Design Optimization

Position gates on thick sections, use multiple gates for large parts, and design efficient runners and cooling systems to balance flow and temperature. Optimize ejectors for smooth demolding and run simulations to adjust before production.

Conclusion

Although stress whitening and stress marking sometimes appear similar and can occur together, distinguishing them in specific products is necessary for effective prevention strategies. As a supplier with years of injection molding experience, Jiangzhi helps customers avoid these defects through design optimization, material selection, and process adjustments. This ensures durable, high-quality parts that meet procurement needs. Contact us for customized solutions to enhance your supply chain.