Thin wall injection molding is a cutting-edge manufacturing process that delivers lightweight, precise, and complex plastic parts. By producing components with wall thicknesses often below 1 mm, thin wall molding meets the demand for cost-effective, high-performance products. However, its unique requirements—high pressures, rapid cycles, and meticulous design—pose challenges that require expertise to overcome. This guide explores the thin wall injection molding process, offering practical design tips and key considerations to ensure success. View the blog and understand thin wall injection molding.

What is Thin Wall Injection Molding?

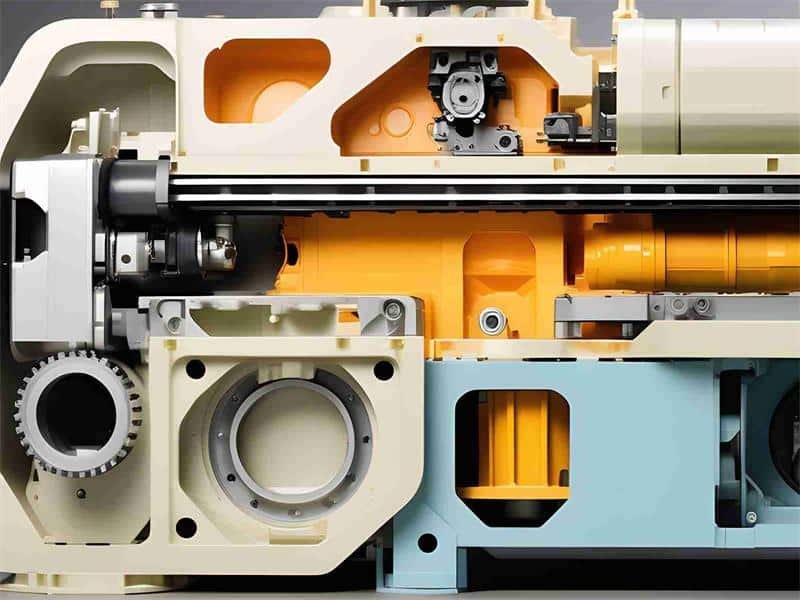

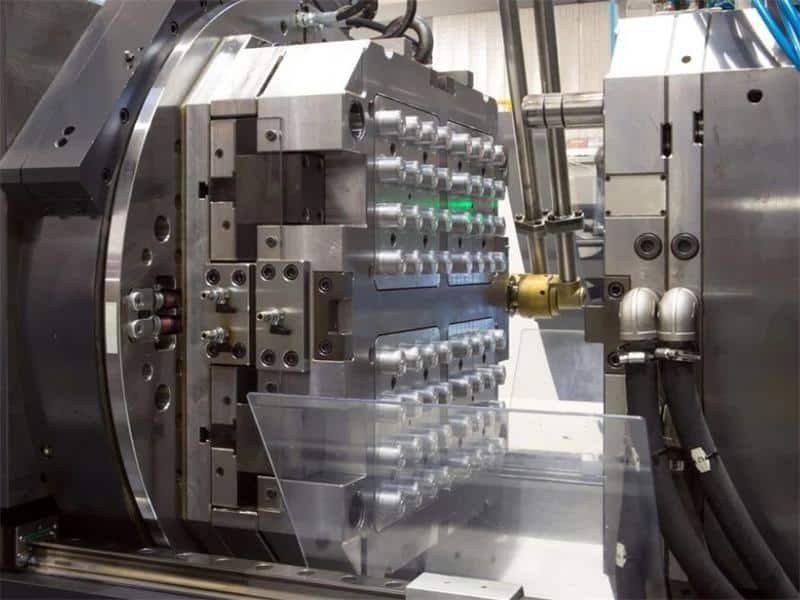

Thin wall injection molding is a specialized injection molding process designed for parts with minimal wall thickness—typically between 0.5 and 0.8 mm. The thin wall injection moulding process involves injecting molten plastic at high pressures (up to 30,000 psi) and speeds into molds with thin cavities, followed by rapid cooling to solidify the part and ensure structural integrity. Unlike traditional injection molding, thin wall molding requires higher pressures, faster cycle times (often under 10 seconds), and high-hardness steel molds (e.g., HRC55+) to withstand extreme conditions, compared to milder P20 steel molds.

Design Tips for Thin Wall Injection Molding

The success of thin wall injection molding hinges on meticulous design to address the challenges of high pressures and thin geometries. The following design tips are important to ensure part quality, minimize defects, and streamline the thin wall injection moulding process. By adhering to these guidelines, you can optimize injection molding thin wall parts for performance and manufacturability.

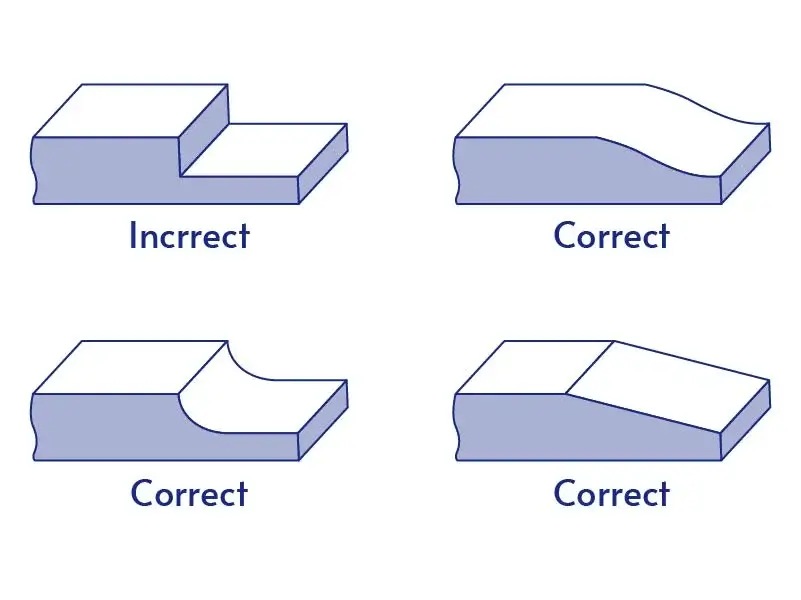

Maintain Uniform Wall Thickness

Uniform wall thickness, ideally between 0.5 and 1 mm, is paramount in thin wall molding to prevent defects like sink marks, warpage, or incomplete filling. Variations in thickness can disrupt material flow, leading to uneven cooling and stress concentrations. To maintain consistency, avoid abrupt transitions and incorporate gradual changes in wall geometry. This ensures smooth filling during the thin wall injection molding process, reducing the risk of voids or distortion.

Optimize Gate Design

Gate design plays a critical role in thin wall injection molding, as it determines how molten plastic fills the mold. Use large or multiple gates to ensure balanced filling, especially for intricate geometries, and consider needle valve timing for precise control in complex parts. Position gates strategically—often at thicker sections or along flow paths—to minimize weld lines and promote even material distribution. Poor gate placement can lead to flow hesitation or air entrapment, compromising part quality.

Select Suitable Materials

The materials means injeciton parts materials and injection molds materials. As injection parts materials, the material flow is critical in thin wall molding. Choose thermoplastics with high flowability, such as resins like HDPE, LDPE, PA, and PP. They can navigate thin cavities effectively. reducing short shots in narrow sections. Avoid sticky materials like polycarbonate (PC), which hinder filling, and use liquid silicone rubber (LSR) cautiously due to flash risks along parting lines. Choose materials that match your part’s geometry and won’t wear the mold at high speeds. Thin-walled injection molds should avoid P20 steel—opt for tougher grades like 718, H-13, or D-2 to handle higher pressure and wear. Though costlier, these steels improve durability and reduce long-term tooling issues.

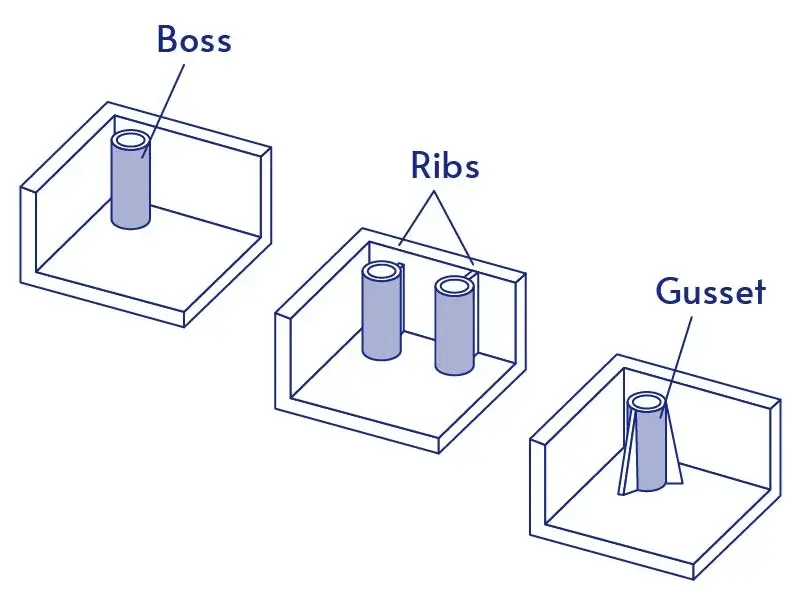

Incorporate Ribs and Bosses Strategically

Ribs and bosses provide structural support in thin wall molding without increasing wall thickness, preserving material efficiency. Keep rib thickness at 50–60% of the wall thickness to avoid sink marks, and ensure ribs are spaced adequately to prevent flow restrictions. Bosses, used for mounting or fastening, should include draft angles (1–2 degrees) to facilitate ejection and minimize stress concentrations. Strategic placement of ribs and bosses enhances part strength while maintaining the lightweight benefits of thin wall injection.

Enhance Exhaust Design

Effective venting is essential in thin wall injection molding to prevent trapped air, which can cause burn marks or incomplete filling. Incorporate exhaust sheets perpendicular to convergence lines, ensuring vents are deep enough to release air without allowing flash. Advanced techniques, such as pre-vacuum molds or negative pressure valves, can further improve exhaust efficiency, particularly for high-speed thin wall injection molding machines.

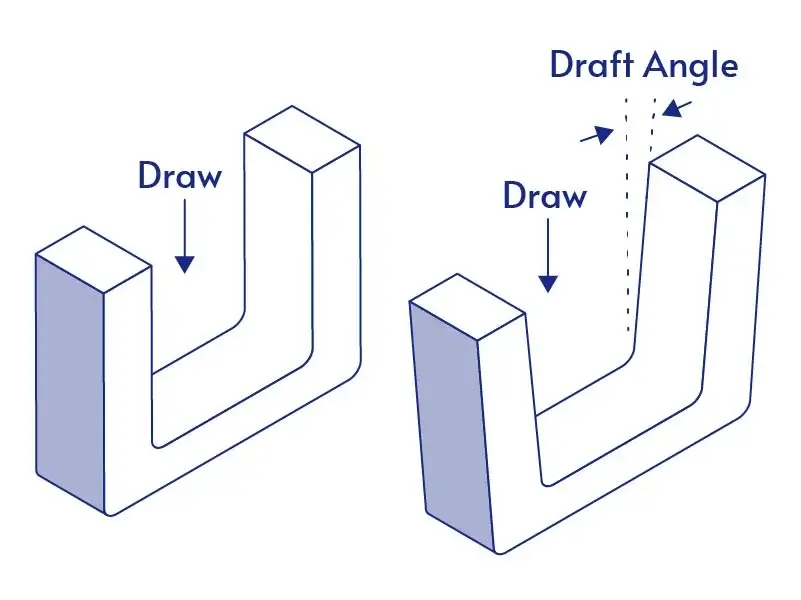

Account for Draft Angles

Draft angles of 1–2 degrees are critical in thin wall molding to facilitate part ejection and reduce mold wear. Thin walls amplify ejection forces, increasing the risk of part damage or mold abrasion without adequate drafts. Apply draft angles consistently to all vertical surfaces, including ribs and bosses, and ensure they align with the mold’s parting line. This design consideration simplifies manufacturing and extends mold life, making thin wall injection more cost-effective and reliable for producing injection molding thin wall parts.

Common Uses of Thin Wall Injection Molding in Manufacturing

Thin wall injection molding is widely employed to produce lightweight, precise components that balance performance and cost. Common applications include food packaging containers like yogurt cups and lids, electronics housings for smartphones and wearables, medical device casings such as syringe barrels, and automotive panels for interior trim. These injection molding thin wall parts leverage the thin wall injection molding process to minimize material usage while delivering durability and precision, making thin wall molding a go-to solution for high-volume manufacturing needs.

Conclusion

Thin wall injection molding presents unique challenges that demand precision and expertise to achieve flawless results. The high injection pressures , thin geometries need high-hardness molds and meticulous design to prevent defects like warpage, sink marks, or incomplete filling. Rapid cycle times and precise material flow further complicate the thin wall injection molding process, making experienced guidance essential. Jiangzhi, a trusted leader in injection, offers comprehensive injection molding services, from advanced mold design to high-speed production. Contact Jiangzhi today to consult on your injection molding projects.