TPE overmolding has become an essential manufacturing technique across various industries, offering a unique combination of flexibility, durability, and aesthetic appeal. Whether it’s enhancing the grip of a power tool handle or providing a soft-touch finish to automotive interior components, tpe overmolding enables to create multi-material parts that improve both functionality and user experience. This comprehensive guide explores what TPE overmolding is, why it is widely used, how to select the right materials, design considerations, common defects and their solutions, typical applications, and the importance of collaborating with experts in this field.

What Is TPE Overmolding?

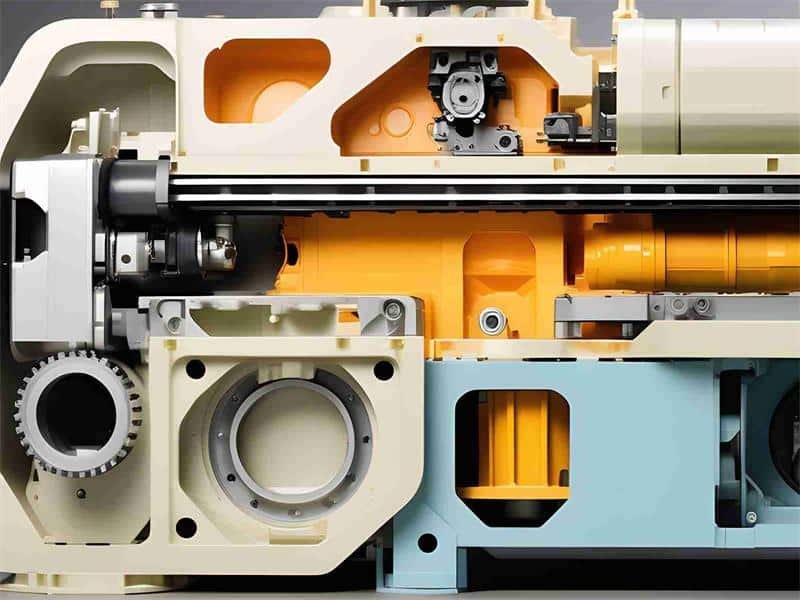

At its core, tpe overmolding is a specialized injection molding process where a layer of thermoplastic elastomer is molded over a rigid or semi-rigid substrate, typically another plastic material. The goal is to combine the desirable properties of both materials into a single, integrated component.

The Process of TPE Overmolding

TPE overmolding typically follows a structured, multi-step process to ensure strong adhesion and high-quality results. From substrate preparation to molding and final finishing, each stage plays a vital role in achieving durable and functional overmolded parts.

- Material Selection: Choose a rigid plastic material for the base. Then select a suitable TPE material that offers flexibility, softness, and good adhesion to the base plastic.

- Mold Design: Design a two-stage mold. The first part forms the rigid substrate, and the second part allows TPE to be injected over it.

- Base Material Injection: Inject the rigid plastic into the mold to create the base part. Allow it to cool and solidify before proceeding to the next step.

- TPE Injection: After the base part has cooled, inject the TPE material into the second cavity of the mold so it flows over the designated areas of the base.

- Cooling and Ejection: Let the overmolded part cool until both materials are fully solidified. Then eject the completed part from the mold.

- Post-Processing and Inspection: Remove any excess material like flash or sprue. Inspect the part to ensure proper bonding, clean surface finish, and absence of defects.

Common Substrate Materials

The most frequently used substrates for TPE overmolding include:

- ABS

- PC

- PA6/PA66

- PP

Why Use TPE for Overmolding?

TPE overmolding offers compelling advantages, making it a preferred choice across industries:

- Enhanced Grip and Comfort: TPE’s soft, rubber-like texture improves ergonomics, as seen in toothbrush handles.

- Shock Absorption: It cushions impacts, protecting components like power tool housings.

- Aesthetic Appeal: Multi-color or textured finishes elevate product design.

- Durability and Sealing: TPE provides water resistance and wear resistance, ideal for gaskets.

- Cost Efficiency: By eliminating adhesives or fasteners, it reduces assembly costs.

TPE Material Selection and Compatibility

Selecting the right TPE and substrate is pivotal for successful TPE overmolding, ensuring strong chemical or mechanical bonding and optimal product performance. TPEs, such as Thermoplastic Polyurethane (TPU), Thermoplastic Vulcanizate (TPV), and Styrene-based TPE-S (SEBS/SBS), are favored for their flexibility, durability, and bonding capabilities. TPU offers high elasticity and abrasion resistance, ideal for handles and automotive components, while TPV provides chemical and heat resistance for seals. TPE-S, with Shore hardness ranging from 25–90A, bonds well with substrates like PP and ABS, enhancing grip in consumer products.

Substrate selection is equally critical, with common choices including ABS, polycarbonate (PC), polypropylene (PP), nylon (PA), and emerging alternatives like polyketone (PK). Each substrate has unique properties affecting compatibility:

| Substrate Material | Properties | Compatibility with TPEs | Bonding Difficulty |

|---|---|---|---|

| ABS | Versatile, impact-resistant | Bonds well with TPE-S, TPU | Easy |

| PC | Tough, transparent, heat-resistant | Strong bonding with TPU, TPE-S | Easy |

| PP | Lightweight, chemical-resistant | Bonds with TPE-S; requires surface treatment | Difficult |

| PA | Strong, wear-resistant | Bonds with specific TPU/TPV; needs pre-drying | Moderate |

| PK | High chemical resistance | Limited TPE compatibility; requires testing | Difficult |

TPE Overmolding Design Guide

Effective TPE overmolding requires meticulous design to ensure robust bonding, high-quality finishes, and defect-free parts. This overmolding design guide outlines the key principles for achieving optimal results.

- Uniform Wall Thickness: Design TPE layers with a thickness of 0.5–3 mm (0.060″–0.120″) to promote even flow and cooling, preventing warping due to uneven shrinkage.

- Smooth Transitions: Incorporate generous radii instead of sharp corners to minimize stress concentrations, which can cause cracking or delamination.

- Precise Mold Tolerances: Maintain mold gaps of 0.01–0.03 mm to eliminate flash, where excess TPE leaks from the mold.

- Optimized Gate Placement: Position gates strategically to achieve uniform TPE flow, avoiding weak weld lines or incomplete fills.

- Substrate Preheating: Preheat substrates to ~100°C to enhance molecular diffusion at the TPE-substrate interface, improving chemical bonding and reducing delamination risks, particularly with materials like PC or nylon.

- Mechanical Interlocks: For substrates with poor chemical adhesion (e.g., POM), design undercuts, holes, or textured surfaces to create mechanical bonds, ensuring TPE remains secure under stress.

- Material Pre-Drying: Pre-dry hygroscopic substrates like nylon to remove moisture, preventing surface defects or weak bonding.

- Cooling Optimization: Design molds with balanced cooling channels to ensure uniform temperature control, minimizing warping or distortion caused by differential cooling rates.

TPE Overmolding Defect Handling and Prevention

Achieving flawless TPE overmolding requires proactive strategies to prevent and address defects such as delamination, flash, warping, and short shots. Below are the common defects and targeted approaches to mitigate these challenges:

- Delamination: Delamination occurs when TPE fails to bond with the substrate, often due to poor material compatibility or moisture. Select TPEs with matching solubility parameters (e.g., TPE-S for PP) and pre-dry hygroscopic substrates like nylon to eliminate moisture-related weak bonding. Preheating substrates to ~100°C enhances chemical adhesion, reducing separation risks.

- Flash: Flash, where excess TPE leaks from the mold, results from loose mold tolerances. Maintain tight mold gaps (0.01–0.03 mm) and optimize injection pressure to prevent material overflow. Regular mold maintenance ensures consistent sealing, especially for high-volume runs.

- Warping: Warping arises from uneven cooling or excessive TPE thickness. Design TPE layers at 0.5–3 mm and incorporate balanced cooling channels in molds to ensure uniform temperature distribution. For instance, a TPE-overmolded PC enclosure avoided warping by adjusting cooling rates and maintaining a 1.5 mm TPE thickness.

- Short Shots: Incomplete mold filling, or short shots, occurs with low injection pressure or poor flow. Increase injection speed and pressure while ensuring proper gate placement (e.g., side gates) for uniform TPE flow. Verify TPE viscosity matches the mold design to prevent blockages.

Common TPE Overmolding Applications

TPE overmolding’s versatility shines in diverse applications, enhancing functionality and user experience:

Toothbrush Handles: TPE provides a soft, non-slip grip for comfort and control.

Power Tool Grips: Absorbs shocks, improving durability and user safety.

Medical Device Seals: Ensures airtight performance in syringes or pumps.

Automotive Gaskets: Offers sealing and weather resistance for long-term reliability.

Electronic Enclosures: Adds water resistance and aesthetic textures to devices.

Conclusion: Work with TPE Overmolding Experts

TPE overmolding transforms product design by blending soft, flexible TPEs with rigid substrates, delivering enhanced grip, durability, and aesthetics. Often achieved through precision TPE injection molding, this process demands expertise in material bonding, mold design, and process control. Partnering with experts ensures your project leverages TPE overmolding’s full potential. Unlock your product’s possibilities with Jiangzhi’s expertise in TPE overmolding and advanced injection molding solutions—contact us today to bring your vision to life.

FAQ About TPE Overmolding Parts

Yes, TPE can be overmolded onto metals like aluminum or steel using mechanical interlocks or textured surfaces for strong bonding.

Use the ASTM D6862 peel test or tensile/shear tests to measure the force needed to separate TPE from the substrate.

Overmolding injects TPE over a pre-molded substrate; co-molding (two-shot molding) injects two materials in one mold for tighter integration.