Transfer molding vs injection molding are two of the most widely used molding techniques in manufacturing, especially in industries requiring precise and high-quality molded parts. Both methods are employed to create complex, durable components, but they differ in their processes, materials, and applications. In this article, we will explore the primary distinctions between transfer molding and injection molding.

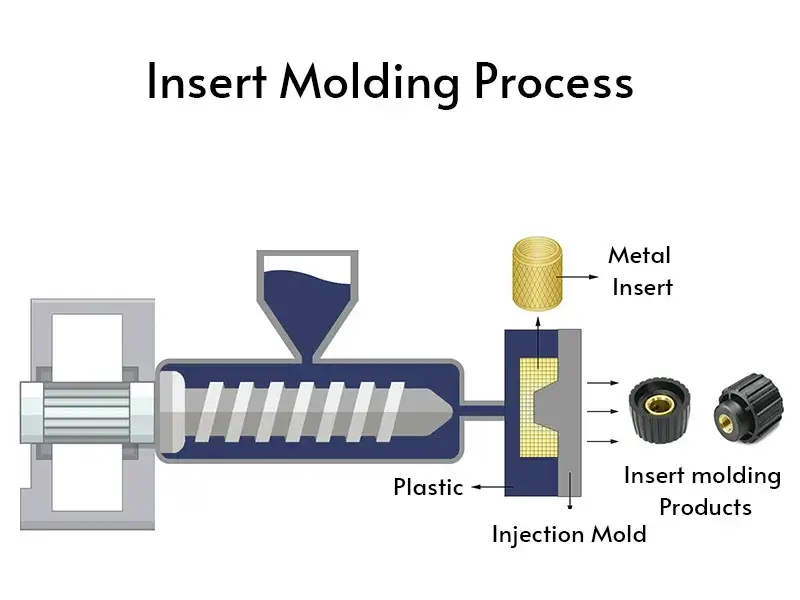

What is Injection Molding?

Injection molding service is a widely used manufacturing process in which material, usually plastic or other material, is melted and injected into a mold under high pressure. Once the material has cooled and solidified, the mold is opened to reveal the finished part. The process works best with thermoplastics such as PP, ABS, and PA, though modified thermosets can also be used.

The injection molding process is particularly well-suited for the mass production of parts with intricate details, high precision, and complex geometries.

Advantages and Disadvantages of Injection Molding

Advantages of Injection Molding

- High Production Rate: Injection molding is capable of producing large quantities of parts quickly and efficiently.

- Precision and Consistency: The process provides high accuracy and consistency in part dimensions, making it ideal for mass production.

- Material Versatility: A wide range of materials, including thermoplastics, thermosets, and metals, can be used in injection molding.

- Complex Geometries: Injection molding is capable of producing parts with intricate shapes and fine details.

Disadvantages of Injection Molding

- High Initial Costs: The cost of designing and producing molds can be high, making it less cost-effective for low-volume production.

- Limited to Certain Materials: Injection molding primarily works well with thermoplastics and some thermosets, but it is not suitable for all types of materials.

- Limited to Wall Thickness: Limited to thinner walls (0.4–12.5 mm); thicker sections risk defects.

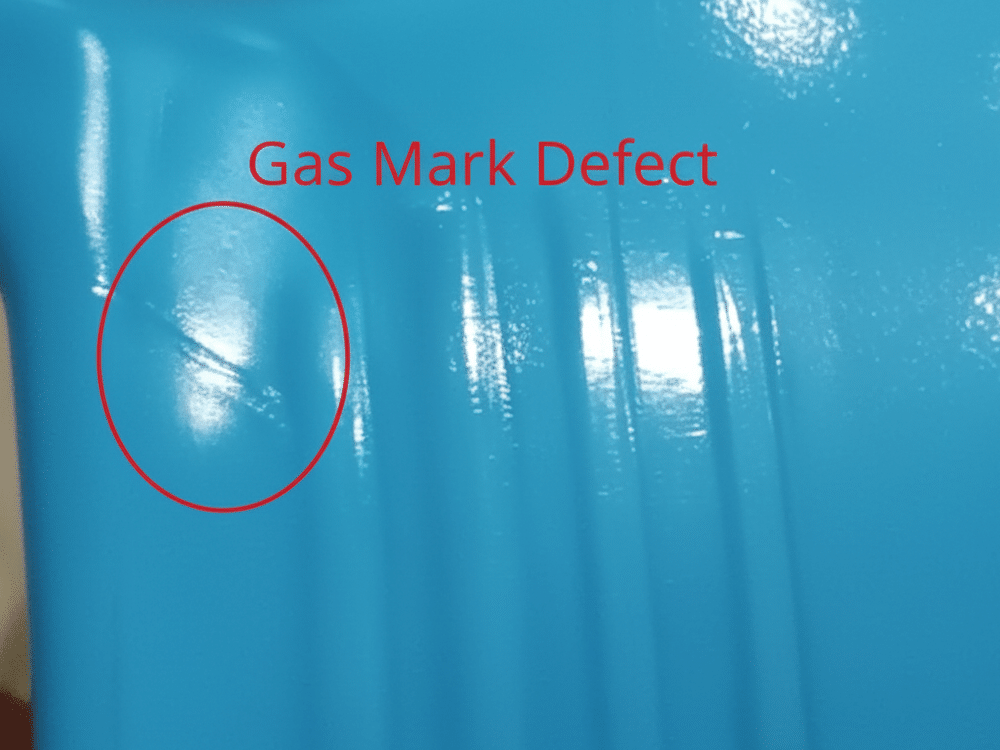

Possible Defects in Injection Molding

- Warpage: Due to uneven cooling, parts can warp, affecting the quality and dimensional accuracy.

- Sink Marks: These are small indentations that appear on the surface of parts due to material shrinkage during cooling.

- Short Shot: This occurs when the mold cavity is not filled with material, leading to incomplete parts.

What is Transfer Molding?

Transfer molding is a widely used manufacturing process for producing high-strength, dimensionally precise parts, primarily from thermosetting plastics such as epoxy, phenolic, and silicone. In this process, a pre-measured amount of material is placed into a heated transfer pot, where it becomes soft and pliable. The material is then forced under pressure into a closed mold cavity, filling intricate shapes and ensuring uniform part quality. After curing, the mold is opened to release the finished part.

Transfer molding is ideal for parts that require superior mechanical properties, excellent surface finish, and the ability to embed inserts such as metal components or fasteners.

Advantages and Disadvantages of Transfer Molding

Advantages of Transfer Molding

- Better Control Over Material Distribution: The material is forced into the mold cavity with higher pressure, which can result in better control over the part’s material distribution and consistency.

- Ideal for Thermosets: Transfer molding is well-suited for thermosetting materials, which require curing and provide better mechanical properties than thermoplastics.

- Lower Waste: Since the material is carefully transferred into the mold, there is typically less waste produced in the process.

Disadvantages of Transfer Molding

- Slower Production Rate: Transfer molding is generally slower than injection molding, especially in high-volume applications.

- Higher Equipment Costs: The equipment for transfer molding can be expensive due to the specialized transfer pot and mold system.

- Material Waste: Excess material may be produced during the process, leading to waste and additional costs.

Possible Defects in Transfer Molding

- Flash: Excess material can seep out from the mold cavity, resulting in unwanted flash, which must be trimmed.

- Incomplete Filling: If the material does not fill the mold cavity completely, it can lead to parts with defects or weaknesses.

- Burning: Due to overheating during the curing process, parts can develop surface burn marks or degrade.

Transfer Molding vs Injection Molding: Key Differences

When comparing transfer molding and injection molding, there are several key differences to consider, which can influence the choice of process based on specific project requirements.

Process

- Injection Molding: Injection molding melts and injects material in one continuous motion using a screw.

- Transfer Molding: Transfer molding separates pre-heating in a pot from the plunger-driven transfer step, requiring post-mold trimming.

Materials

- Injection Molding: Can accommodate a wide range of thermoplastics, thermosets, and even metals (for metal injection molding).

- Transfer Molding: Primarily used for thermosetting plastics, resins, and rubbers, making it ideal for high-performance parts.

Production Speed

- Injection Molding: Injection cycles run from 2 seconds to 2 minutes with multi-cavity capability. Faster and better suited for high-volume production.

- Transfer Molding: Transfer cycles extend due to loading, heating, and trimming. Slower compared to injection molding, which may make it less suitable for large-scale production.

Precision and Complexity

- Injection Molding: Injection molding offers high precision and can produce complex geometries and fine details. Injection molding suits thin, rounded features.

- Transfer Molding: Transfer molding provides good precision, but is more suited to parts with simpler shapes. Transfer molding allows sharp corners and thicker walls. This process is often used in automotive, electrical, and medical applications.

Cost

- Injection Molding Cost: Although the initial cost of molds is high, it becomes cost-effective for mass production due to fast cycle times.

- Transfer Molding Cost: Transfer molding starts cheaper yet incurs higher waste and labor costs.

Applications

- Injection Molding: Widely used in industries such as automotive, consumer goods, electronics, and medical devices for producing high-volume plastic parts.

- Transfer Molding: Often used in industries that require thermoset materials, such as automotive (for rubber seals and gaskets), electrical (for insulators), and medical (for durable components).

How to Choose Between Transfer Molding and Injection Molding?

When choosing between transfer molding and injection molding, the decision should be based on factors such as material type, production volume, part complexity, and desired precision. For high-volume production of complex plastic parts with fine details, injection molding is usually the better choice due to its faster cycle times and cost-effectiveness.

However, if the project requires the use of thermosetting materials or involves small to medium production runs with high-strength, durable parts, transfer molding may be more suitable. Consider the specific needs of your project, including material properties and production scale, to determine the most appropriate molding method.

Conclusion

Each serves different manufacturing goals, from precision plastic production to durable thermoset applications. At Jiangzhi, we combine technical expertise with advanced molding capabilities to turn your designs into reliable, production-ready components. Contact us today to find the best molding solution for your next project.