What is Nylon Casting?

Nylon casting is a process used to produce cast nylon material by polymerizing liquid monomer directly in molds, rather than melting and shaping pre-made polymer pellets. The most common cast nylon material is based on caprolactam, which is polymerized into nylon 6 through a controlled chemical reaction in heated molds. Nylon casting allows the material to form directly into near-net shapes such as sheets, rods, tubes, and custom blocks with low internal stress and good dimensional stability.Nylon Casting Manufacturing Process

The manufacturing of cast nylon involves a series of steps that ensure the material achieves its desired properties.Preparation of Monomers

The process begins with caprolactam, the primary monomer for nylon 6. This is mixed with a catalyst, such as sodium caprolactamate, and an activator like N-acetyl caprolactam. The mixture is heated to around 80-100°C to form a low-viscosity liquid. At this stage, it is also possible to introduce fillers, lubricants, colorants, or reinforcing agents to modify the final properties of the cast nylon material for specific applications.Mold Preparation

Molds are preheated to approximately 140-160°C. These molds can be made from metal or other heat-resistant materials and are designed to accommodate the expansion during polymerization. For larger parts, vacuum or pressure assistance may be used to ensure even filling.Pouring and Polymerization

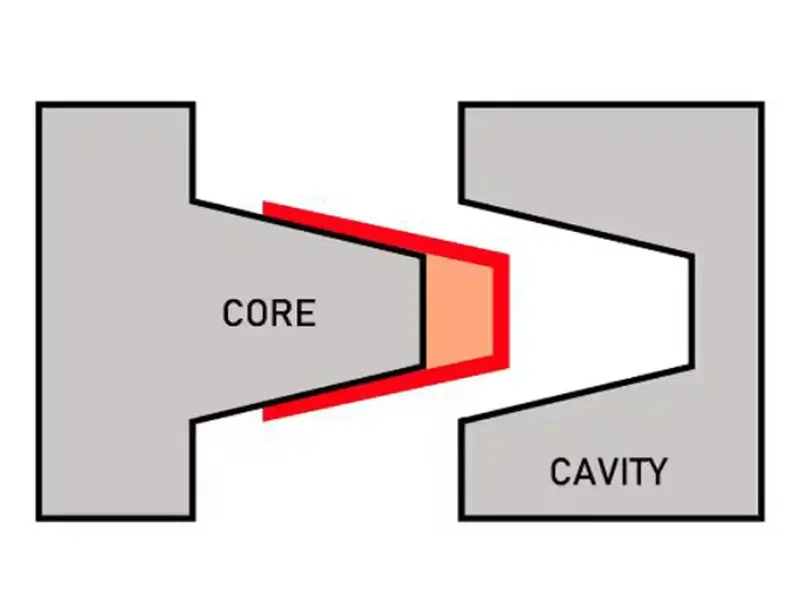

The liquid mixture is poured into pre-heated molds or open casting tools. The polymerization reaction takes place inside the mold, generating heat and gradually turning the liquid into a solid nylon cast material with the desired dimensions.4. Cooling and Demolding

After polymerization, the part is allowed to cool gradually to room temperature. Once cooled, the component is removed from the mold. Annealing may follow, involving heating the part to 100-150°C for several hours to relieve any residual stresses and stabilize dimensions.Post-Processing(If Necessary)

The cast nylon material may undergo machining, such as cutting or drilling, to achieve final specifications.Comparison of Nylon Casting with Other Nylon Processes

Cast nylon differs from other nylon production methods in several key aspects. Below is a table comparison of extruded nylon and injection-molded nylon.| Aspect | Cast Nylon | Extruded Nylon |

|---|---|---|

| Temperature Range | 140-160°C | 220-250°C |

| Pressure Requirement | Low | Medium |

| Part Size Suitability | Large/Thick | Medium/Uniform |

| Internal Stress | Low | Moderate |

| Cost for Custom Parts | Low | Medium |

| Typical Applications | Bearings, Gears | Rods, Tubes |

Core properties and advantages of cast nylon

Cast nylon material is known for its good combination of mechanical strength, toughness, and wear resistance.

High Mechanical Strength and Load Capacity

Cast nylon material provides a combination of tensile, compressive, and impact strength suitable for many load-bearing components, allowing it to replace metal in numerous industrial applications. Its ability to withstand medium to high static and dynamic loads supports use in gears, sheaves, and structural elements.

Excellent Wear Resistance and Low Friction

Cast nylon offers good abrasion resistance and low friction against metal surfaces, which helps reduce wear on both the plastic part and the mating component. This property supports longer service life and lowers the need for frequent replacement in sliding, rolling, and oscillating applications.

Reduced Noise and Vibration

Compared with metal components, cast nylon material naturally damps vibration and operates more quietly in dynamic systems. This leads to a more stable and quieter working environment, especially in conveying, lifting, and material-handling equipment.

Chemical Resistance and Corrosion-Free Performance

Cast nylon is resistant to many oils, greases, fuels, and common industrial chemicals, maintaining its integrity where metal parts may corrode. The absence of rust and corrosion reduces maintenance demands and supports reliable operation in harsh environments.

Lightweight Design with Easier handling

The density of cast nylon is significantly lower than that of steel and many other metals, enabling lighter components without sacrificing key mechanical properties. Lighter parts simplify installation, maintenance, and handling, and in rotating systems can contribute to reduced energy consumption.

Dimensional Stability and Low Internal Stress

Because cast nylon is formed by in-situ polymerization rather than cooled from a high-melt state, it often exhibits lower internal stress and better dimensional stability than some melt-processed plastics. This supports tighter tolerances, reduced warpage, and more predictable performance over the service life of the part.

Customizable Formulations for Specific Needs

The nylon casting process allows the introduction of lubricants, solid fillers, and reinforcing agents to create tailored grades, such as oil-filled or reinforced cast nylon. These customized formulations enable optimization for particular requirements, including higher wear resistance, improved self-lubrication, or increased stiffness and load capacity.

Suitability for Large and Complex Parts

Cast nylon can be produced in large blocks, thick plates, and big-diameter tubes that are not practical with standard injection molding. This capability supports the cost-effective manufacture of oversized sheaves, rollers, and custom machined components from a single casting.

Applications of Cast Nylon in Industry

Cast nylon is commonly machined into a wide range of functional components across industries.

- Rollers, Wheels, and Cylinders: Conveyor rollers, chain rollers, crane wheels, press rolls, idler rollers, star wheels (bottling lines), and aggregate handling rollers.

- Pulleys, Sheaves, and Belt Guides: Power transmission pulleys, timing belt guides, sheaves, cam followers, and textile machine pulleys.

- Bushings and Bearings: Bushings for rotating equipment, suspension systems, excavators, pumps, and valves.

- Guides, Rails, and Wear Strips/Plates: Conveyor guides, chain guides, thread/yarn guides, wear strips (looms and paper machines), chassis wear plates, skirt boards, slide plates, and precision slide rails.

- Liners and Impact/Wear-Resistant Plates: Chute liners, bucket/hopper liners, dump truck bed liners, impact plates, crusher wear components, outrigger pads, and forming boards.

- Seals and Valve Components: Valve seats, seals, filter press plates/seals, pipe supports, and flanges.

- Pump and Agitator Parts: Pump impellers and agitator blades.

- Gears and Sprockets: Power transmission gears and sprockets.

- Insulating and Precision Components: Insulating parts, spacers, custom fixtures/jigs, and low-friction slides (automation systems).

- Other Specialized Components: Cutting boards, engine mounts, vibration dampers, tensioners, and custom wear parts.

Conclusion

Nylon casting is not the same as ordinary nylon injection molding. With the development of nylon casting technology, more applications are shifting toward customizing material formulations and sizes based on specific operating conditions. This customization further expands the application space of cast nylon in the industrial field. Jiangzhi is experienced in material formulation, process control, and machining. Choose Jiangzhi as your production and manufacturing partner to access tailored cast nylon solutions that meet your needs.