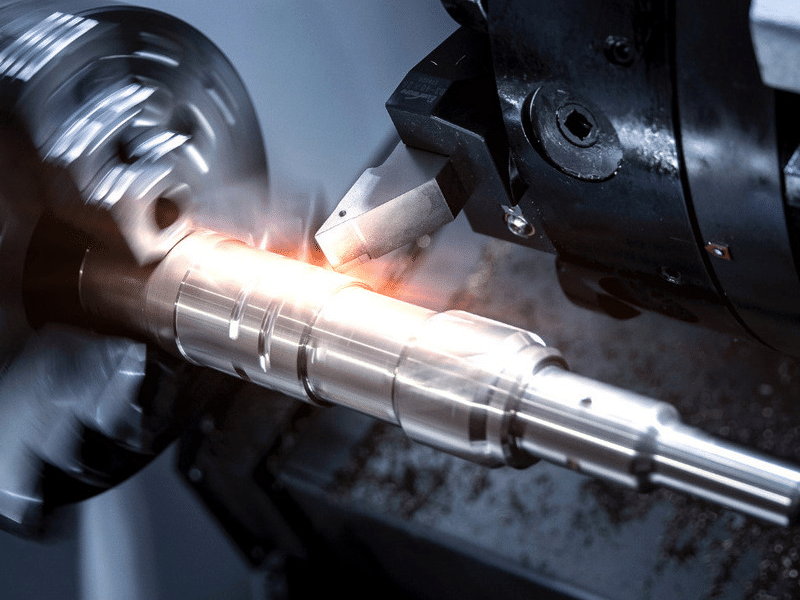

Custom CNC LDPE Machining Service

CNC Machining in LDPE Material

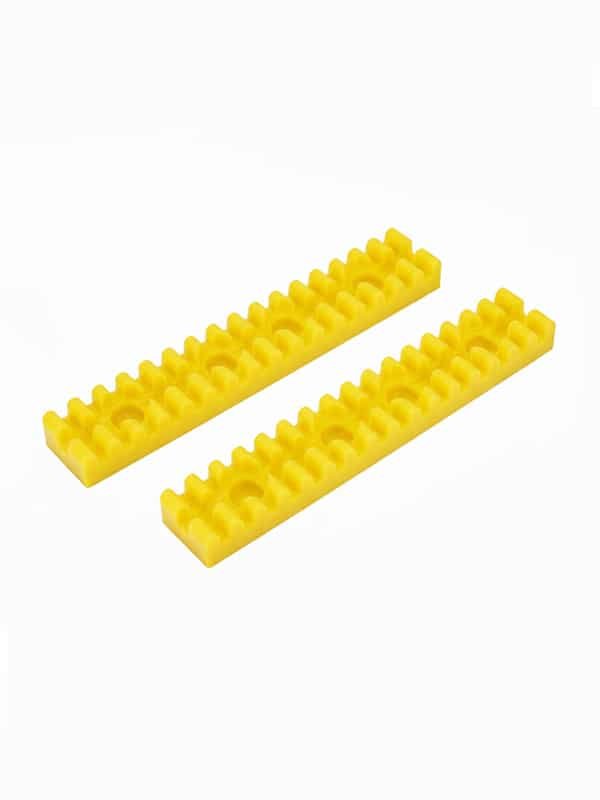

At Jiangzhi, we specialize in CNC LDPE machining, offering tight tolerances, reliable quality, and quick production times. From early-stage prototypes to low-volume manufacturing, we transform your designs into durable, flexible, and high-performance plastic components. LDPE is easy to machine and works well for parts requiring flexibility, chemical resistance, or lightweight properties.

Our one-stop plastic CNC machining service includes material selection, LDPE milling, part finishing, and final inspection. Common applications of machined LDPE parts include fluid system liners, protective covers, low-friction components, packaging machinery parts, and chemical handling equipment. With our experience, we help reduce lead times, streamline production, and meet demanding project schedules.

| Price | $$$ |

|---|---|

| Tolerances | ±0.02mm |

| Maximum Part Size | 900mm x 600mm x 250mm |

| Minimum Feature Size | Φ 0.8mm |

| Wall Thickness | 1mm |

| Lead Time | About 3-6 days |

Machining LDPE Plastic Properties

| Tensile Strength, Yield (MPa) | Elongation at Break | Hardness | Impact Strength | Heat Deflection | Heat Deflection Temperature | Melting Point |

|---|---|---|---|---|---|---|

| 8–25 MPa | 100–650% | R45–R65 | 60–110 J/m | 45–70°C | 40–60°C | 105-115°C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Related Process

Need High-Performance LDPE CNC Components?

Advantages & Disadvantages of CNC LDPE Machining

-

Avantages

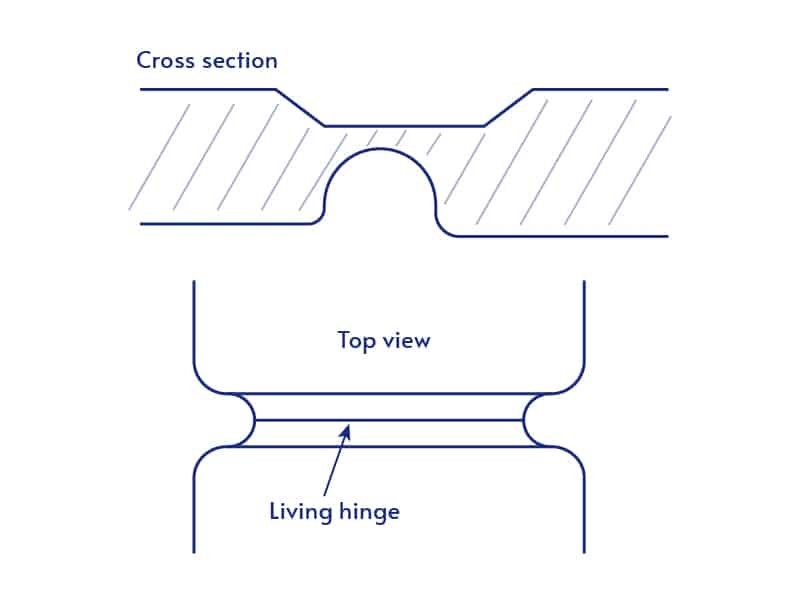

- Excellent flexibility — ideal for parts requiring bending or low-stress deformation

- Good chemical resistance — suitable for mild acids, bases, and solvents

- Lightweight & low friction — reduces wear in sliding or guiding applications

- Easy to machine — minimal tool wear and clean surface finish

- Cost-effective — affordable for prototyping and small production runs

-

Disadvantages

- Lower rigidity — not suitable for high-load structural components

- Limited temperature resistance — can deform under moderate heat

- Poor UV resistance — may degrade if exposed to sunlight without stabilization

- Dimensional changes — higher thermal expansion may require design compensation

Surface Finishing Options for CNC Machined LDPE Parts

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Jiangzhi CNC LDPE Machining Parts are Guaranteed