CNC Machining Delrin Service

CNC Machining in POM Material

At Jiangzhi, we specialize in POM CNC machining (also known as Delrin CNC machining) to deliver strong, wear-resistant parts with exceptional dimensional stability. Our CNC POM parts combine low friction, excellent toughness, and tight tolerances, helping you accelerate time-to-market and reduce manufacturing risk. We bring your custom Delrin part designs to life with precision and care.

Thanks to our deep experience in machining acetal plastic, we can efficiently process complex geometries, thin walls, and intricate cuts. From material selection to post-machining finishing, we offer complete, customized CNC machining services that support your goals in industries such as: Automotive (bushings, gears, housings), Electronics (insulating components, structural parts), Industrial equipment (rollers, spacers, bearings), Medical (instrument handles, diagnostic brackets).

| Price | $$$ |

|---|---|

| Tolerances | ±0.01mm |

| Maximum Part Size | 2000mm x 1500mm x 500mm |

| Minimum Feature Size | Φ 0.5mm |

| Wall Thickness | 0.75mm |

| Lead Time | About 3-6 days |

Acetal Machining Material Properties Machining

| Tensile Strength, Yield (MPa) | Elongation at Break | Hardness | Impact Strength | Heat Deflection | Heat Deflection Temperature | Melting Point |

|---|---|---|---|---|---|---|

| 60–70MPa | 20–60% | R120 | 90–130J/m | 110°C | 100–120°C | 165–175°C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

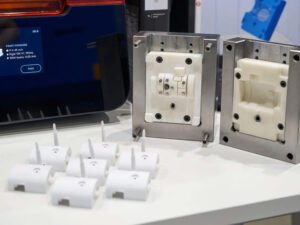

Related Process

Looking for High Precision CNC Machining Delrin?

Advantages & Disadvantages of CNC Machining Delrin

Selecting CNC POM plastic machining is a smart choice for precision parts—but knowing the pros and cons of custom CNC machined POM components is key to maximizing performance and efficiency.

Advantages

- Exceptional machinability – allows tight-tolerance turning, drilling, and milling acetal plastic

- Low friction and high strength – ideal for parts under repetitive motion

- Moisture and chemical resistance – stable in humid or chemically exposed environments

- Superior dimensional accuracy – excellent for parts needing precision fits

Disadvantages

- Poor bonding properties – not suitable for adhesive assembly

- Low UV resistance – may degrade with prolonged sun exposure

- Flammable without additives – may require flame-retardant grades

- Harder to paint or print – post-processing may be needed for labeling or finishes

Surface Finishing Options for CNC Machined Delrin Parts

At Jiangzhi, we have the expertise and capabilities to deliver a wide range of surface finishing options for CNC machined Delrin parts. Whether your project demands enhanced appearance, improved functionality, or precise customization, our finishing solutions are tailored to meet your specific requirements.

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Guaranteed Quality for Your CNC Machining Delrin Parts