Custom CNC Polycarbonate Machining

Polycarbonate (PC) CNC Machining Service

At Jiangzhi, we specialize in high-precision CNC machining of custom polycarbonate parts, including transparent, black, and glass-filled grades. We deliver durable, clear, and impact-resistant components with fast turnaround.

Thanks to PC excellent impact resistance and optical clarity, polycarbonate is widely used in medical devices, electronics, automotive, and aerospace industries. Our team expertly handles CNC machining of PC parts, overcoming challenges like melting or cracking. From material selection to surface finishing, we offer tailored, end-to-end solutions for your custom polycarbonate parts.

| Price | $$$ |

|---|---|

| Tolerances | ±0.02mm |

| Maximum Part Size | 1500mm x 1200mm x 400mm |

| Minimum Feature Size | Φ 0.8mm |

| Wall Thickness | 1mm |

| Lead Time | About 3-6 days |

Polycarbonate CNC Machining Parts Process

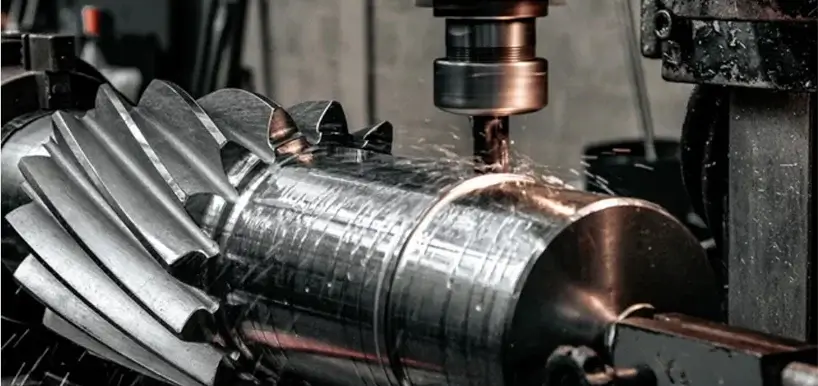

Polycarbonate CNC Milling

Polycarbonate CNC Turning

Polycarbonate Machining Properties

| Tensile Strength, Yield (MPa) | Elongation at Break | Hardness | Impact Strength | Heat Deflection Temperature | Melting Point | Transparency |

|---|---|---|---|---|---|---|

| 61.0MPa | 110% | Rockwell R118 | 850 J/m | 135 °C | 267 °C | High (Light Transmittance >88%) |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Related Process

Need Impact-Resistant & Transparent PC CNC Parts?

Advantages & Disadvantages of PC CNC Machining

Benefits of Machining Polycarbonate CNC Service

- Extremely high impact resistance – almost unbreakable, ideal for demanding use.

- Optical clarity – excellent light transmission, perfect for clear parts.

- Dimensional stability – maintains precision even under stress.

- Good thermal resistance – suitable for moderately high temperatures.

Polycarbonate CNC Machining Parts Application

- Eyewear lenses

- Automotive dashboards and interior parts

- Electronic device covers

- Medical device housings

- Safety shields

- Signage and display panels

Surface Finishing Options for CNC Machined Parts

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Jiangzhi CNC Custom Polycarbonate Part is Guaranteed

100% satisfaction: Polycarbonate cnc machining parts with exceptional clarity, high heat resistance, and outstanding dimensional stability – your polycarbonate custom machined parts, delivered with precision and confidence.

FAQs About CNC Polycarbonate Machining

The CNC pc parts price depends on the part’s structure, order volume, and machining process. You can leave a message on our website.

PC can handle temperatures up to ~135°C. It’s more heat-resistant than ABS but less than materials like PEEK.

PC is tougher and more impact-resistant. Acrylic offers better scratch resistance and optical clarity but is more brittle.

Yes, CNC machined PC can be polished to near-optical clarity with the right finishing processes.

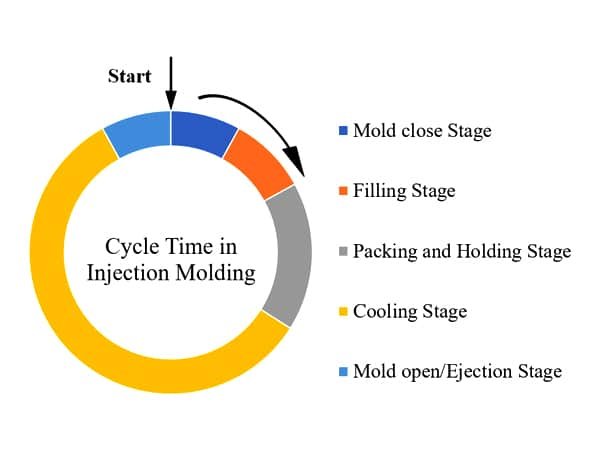

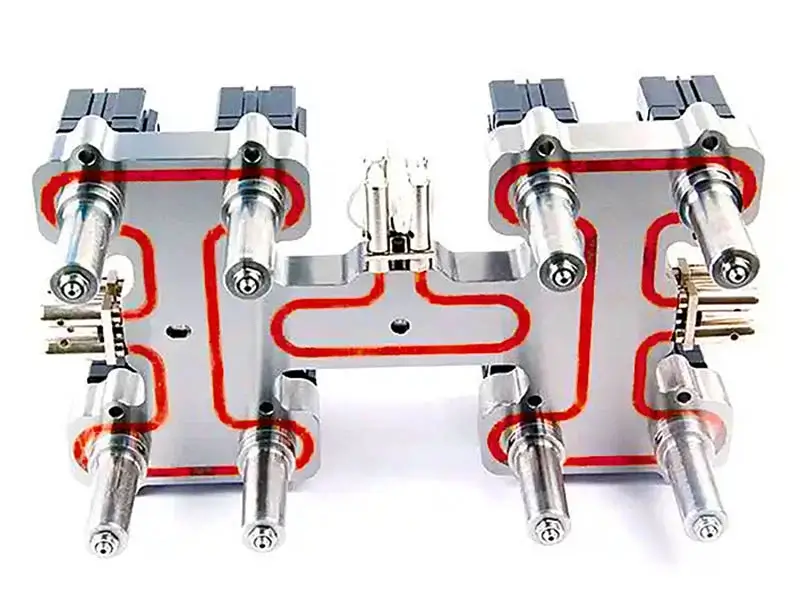

PC CNC machining is faster and more flexible for low volumes or complex geometries. PC molding is better for mass production.