Acrylic CNC machining is a precision manufacturing process, offering a versatile and cost-effective way to craft intricate parts from polymethyl methacrylate (PMMA). This transparent thermoplastic, often hailed as a glass alternative, blends aesthetic appeal with robust functionality. This article delves into the process, its benefits, material properties, precautions, common challenges, and diverse applications.

What is Acrylic CNC Machining?

Acrylic CNC machining refers to the use of computer numerical control (CNC) systems to shape acrylic into precise transparent parts. By leveraging tools like mills, lathes, and lasers, CNC machining acrylic achieves intricate designs with minimal waste. The process encompasses several techniques, including acrylic milling, turning, engraving, and laser cutting.

Why Choose Acrylic for CNC Machining?

Acrylic stands out in CNC plastic machining for its unique blend of properties. Its transparency, with a light transmittance of 92%, rivals glass but offers superior durability—five times stronger, in fact. This makes CNC machining acrylic a go-to for applications requiring optical clarity, such as lenses or display cases. Additionally, acrylic is lightweight, weighing half as much as glass, which simplifies handling and reduces shipping costs. Another reason to opt for acrylic milling is its versatility. Acrylic can be milled, turned, engraved, or laser-cut with ease, accommodating a wide range of designs. Compared to polycarbonate, acrylic boasts better UV resistance, ensuring long-term clarity in outdoor applications. Its cost-effectiveness also makes it an attractive choice for budget-conscious projects.

PMMA’s Main Properties

Polymethyl methacrylate (PMMA) is a versatile thermoplastic known for several key properties that make it widely used in various applications:

- Transparency: PMMA boasts remarkable clarity, transmitting up to 92% of visible light with a refractive index of 1.49. This optical surpasses glass, making it ideal for lenses, displays, and signage in acrylic milling.

- Impact Resistance: Approximately 17 times stronger than glass, PMMA resists shattering, enhancing safety in applications like security windows or protective barriers crafted.

- UV Protection: Acrylic naturally blocks harmful ultraviolet rays, safeguarding objects behind it, such as museum artifacts or outdoor signage, from sun-induced degradation.

- Weather Resistance: PMMA maintains chemical and physical stability in harsh outdoor conditions. Its dimensional stability minimizes size changes due to temperature fluctuations.

- Thermal Insulation: With a lower thermal conductivity than glass, PMMA is an effective insulator, ideal for greenhouse panels or skylights produced via acrylic CNC machining.

- Chemical Resistance: PMMA withstands exposure to many household acids, alcohols, and hydrocarbons, making it suitable for laboratory equipment or cleaning agent containers in CNC milling acrylic.

- Ease of Maintenance: Acrylic surfaces are easily cleaned and polished with simple compounds, restoring original gloss and clarity.

Precautions for CNC Acrylic Machining

Achieving perfect results in acrylic CNC machining requires properly choosing tooling, cutting strategies, and machine settings to prevent defects like melting or chipping. Below are key precautions to ensure precision and quality in CNC acrylic processes:

- Choose the Right Cutter: Select razor-sharp, robust cutters to prevent acrylic from melting, which compromises aesthetics and functionality in acrylic milling. Avoid cutters previously used on metal, as they may have jagged edges that cause poor surface finishes. Carbide cutters are preferred for CNC machining acrylic due to their balance of durability and smooth cutting, outperforming high-speed steel (lesser finish) and diamond cutters (costly). Use cutters with a 5° rake angle and 2° clearance angle for optimal performance.

- Use Appropriate Bits and Ramps: Opt for carbide O-Flute End Mill Bits, designed specifically for CNC acrylic drilling and cutting, to create clean holes and edges. Dull bits lead to stress cracking or crazing, so maintain sharpness. When drilling, employ a smooth ramp to plunge the bit, minimizing damage and ensuring a polished finish in CNC milling acrylic.

- Monitor Cutting Depth and Direction: Control cutting depth to avoid excessive force, which can crack acrylic. Ensure awareness of the cutter’s rotation direction (clockwise or counterclockwise) to align with design features, maintaining accuracy in acrylic CNC machining. Incorrect direction risks flawed geometries or rough surfaces.

- Set Optimal Feed Rate and Speed: Adjust feed rates to balance speed and quality. Fast feed rates prevent melting by reducing heat buildup, but excessive speed can dislodge parts or cause blemishes in CNC plastic machining. Slow feed rates may produce rough, inaccurate surfaces. Tailor feed rates to acrylic type (cast or extruded) and part geometry for best results.

Common Issues and Solutions in Acrylic CNC Machining

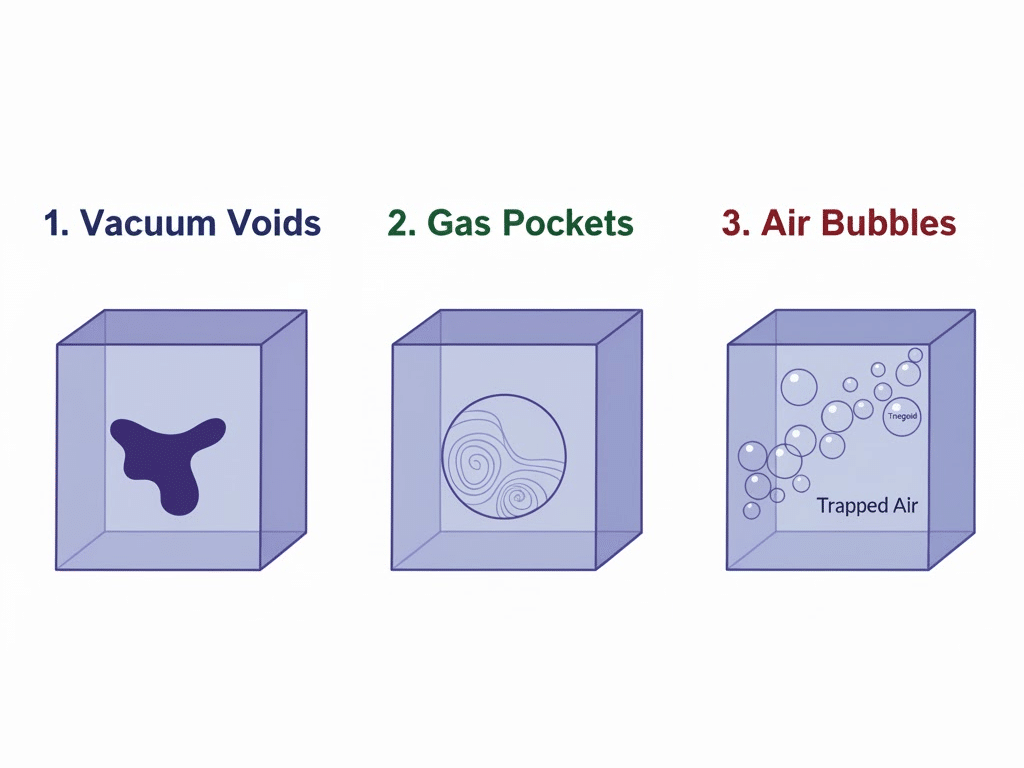

Despite its advantages, CNC plastic machining with acrylic can encounter challenges. Below are common issues and their solutions:

- Melting: Excessive heat from high spindle speeds or dull tools can soften acrylic, leading to poor surface quality. To prevent this, use sharp, single-flute end mills and lower spindle speeds while increasing feed rates. This minimizes heat buildup, ensuring pristine cuts in acrylic milling.

- Chipping or Cracking: High cutting forces or improper tools can cause acrylic to chip or crack. Opt for polished tools and reduce cutting depth to distribute forces evenly. This is particularly important in CNC milling acrylic for intricate designs.

- Surface Scratches: Acrylic’s surface is prone to scratching during machining. Post-processing techniques like flame polishing or sanding can restore a glossy finish. Protective films during CNC acrylic processing also help.

- Dimensional Inaccuracy: Misaligned machines or loose fixturing can lead to errors. Regular calibration and secure workholding ensure precision in acrylic CNC machining.

Surface Treatment in Acrylic CNC Machining

Surface treatment enhances the aesthetic and functional qualities of CNC-machined acrylic parts, ensuring polished, professional finishes. Common techniques in acrylic CNC machining surface treatment include flame polishing, sanding, buffing, and coating, each addressing specific needs like clarity, scratch resistance, or durability.

Flame Polishing: This method uses a controlled flame to melt the acrylic’s surface slightly, creating a glossy, glass-like finish. It’s ideal for edges cut during CNC milling acrylic, removing tool marks and enhancing clarity.

Sanding and Buffing: Wet sanding with fine-grit sandpaper removes surface scratches, followed by buffing with a polishing compound to restore PMMA’s natural sheen. This is effective for large surfaces machined via CNC plastic machining, ensuring uniformity.

Coating: Applying protective coatings, such as anti-scratch or UV-resistant films, enhances durability.

Vapor Polishing: For intricate geometries, vapor polishing uses chemical vapors to smooth surfaces without physical contact, preserving precision in acrylic milling.

Applications of CNC-Machined Acrylic Parts

The versatility of acrylic CNC machining makes it indispensable across industries. Here are some key applications:

Advertising: CNC acrylic processes create intricate logos and patterns with precision, enhancing brand visibility.

Automotive: Strength and UV resistance make the CNC milling of acrylic produce durable headlight lenses, tail light covers, and dashboard components.

Medical: Acrylic’s biocompatibility and clarity make it suitable for instrument casings, diagnostic equipment, and protective shields.

Construction: Acrylic panels serve as lightweight, shatter-resistant alternatives to glass in windows, skylights, and partitions.

Consumer Goods: From display cases to decorative home accents, CNC acrylic creates aesthetically pleasing, durable products.

Conclusion

Acrylic CNC machining service offers a powerful blend of precision, versatility, and cost-effectiveness, transforming PMMA into components that excel in clarity, strength, and durability. By understanding the intricacies of CNC acrylic processes—such as acrylic milling and CNC milling acrylic—manufacturers can unlock its full potential. For tailored advice or project support, contact a Jiangzhi expert to bring your vision to life.