Acrylic injection molding has emerged as a pivotal process in modern manufacturing, transforming polymethyl methacrylate (PMMA) into transparent, durable components that rival glass in clarity but surpass it in versatility. Known for its aesthetic appeal and robust properties, PMMA molding is widely adopted across industries, from automotive to medical. This article explores acrylic’s characteristics, the benefits of acrylic plastic molding, the injection molding process, design guidelines, common defects, and applications.

What is Acrylic Injection Molding?

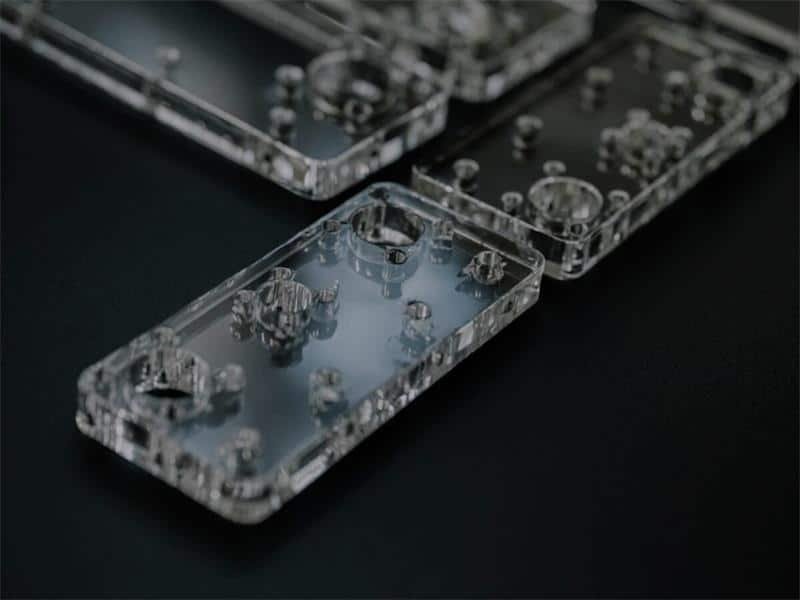

Acrylic injection molding is a precise manufacturing process that uses molten acrylic resin to produce clear, durable plastic components. By injecting the material into a custom-designed mold under high pressure, this method ensures excellent dimensional accuracy, smooth surfaces, and exceptional transparency. It offers a reliable way to create complex shapes efficiently while maintaining the optical clarity that makes acrylic stand out among other plastics.

Properties of Acrylic Materials Chart

| Property Category | Specification / Value | Description / Application |

|---|---|---|

| Optical Properties | Light Transmittance: ≈92% | High transparency, ideal for clear components |

| Refractive Index: ≈1.49 | Close to glass, suitable for lenses and display screens | |

| UV Filtering: Blocks <300nm | Prevents aging and discoloration from UV, used in outdoor & medical applications | |

| Mechanical Properties | Tensile Strength: ≈75 MPa | Provides good structural support |

| Flexural Strength: ≈90 MPa | Suitable for parts under bending stress | |

| Glass Transition Temp: ≈105°C | Works in normal and low-temperature environments | |

| Young’s Modulus: 1.8–3.1 GPa | Offers good rigidity | |

| Environmental Stability | UV Resistance: Good | Suitable for outdoor use, e.g., automotive lenses, windows |

| Chemical Resistance: Resistant to most chemicals | Avoid strong acids and bases | |

| Processing & Machining | Machinability: Easy to cut, drill, polish, thermoform | Supports secondary processing |

| Coating & Coloring: Can be coated or dyed | Meets aesthetic and functional requirements | |

| Recyclability: Recyclable | Environmentally friendly |

PMMA Injection Molding: Advantages and Disadvantages

Acrylic (PMMA) is a versatile plastic widely used in injection molding for its clarity, strength, and design flexibility.

Acrylic injection molding offers high transparency, excellent design flexibility, and good mechanical strength, allowing for complex shapes and smooth, glossy surfaces directly from the mold. It resists UV degradation, supports secondary machining such as cutting, drilling, and polishing, and is recyclable, making it environmentally friendly.

However, PMMA is relatively brittle compared to materials like polycarbonate, has limited heat resistance (glass transition ~105°C), and may experience shrinkage or warpage if processing conditions are not carefully controlled. Improper molding can also cause defects like flow lines or stress marks, and the material is more expensive than many commodity plastics, with sensitivity to strong acids, bases, and certain solvents.

Acrylic Injection Molding Process Overview

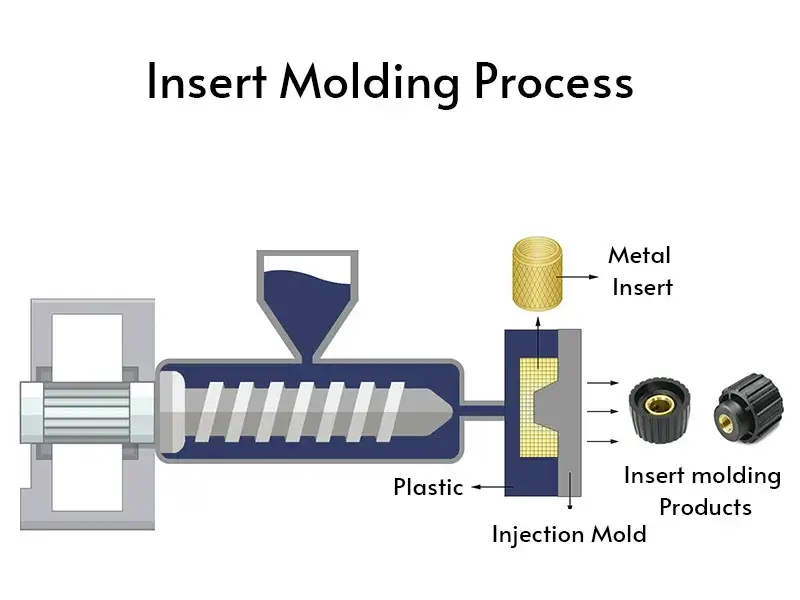

The acrylic injection molding process involves injecting molten acrylic into a mold to create parts with specific shapes and properties.

1. Mold Design and Preparation:

Designers use 3D CAD software to model the molds precisely. The mold design accounts for factors such as part geometry, gate locations, cooling channels, and ejector pin placement.

2. Material Preparation:

Acrylic resin, usually in the form of granules or pellets, is hygroscopic and needs to be dried to remove moisture, which can cause defects in the molded products. The drying process typically occurs at around 80°C for 2–4 hours.

3. Injection Molding Machine Setup:

The mold is mounted onto the injection molding machine, and parameters such as injection speed, temperature, and pressure are programmed. Clamping pressure is applied to securely close the mold halves, preventing molten plastic from leaking during injection.

4. Injection Process:

The dried acrylic pellets are fed into the injection molding machine, where they are heated until molten. The molten acrylic is then injected into the mold cavity under high pressure.

5. Cooling and Solidification:

Once the mold is filled, the acrylic is allowed to cool and solidify. Water channels or other cooling mechanisms integrated into the mold facilitate this process.

6. Mold Opening and Ejection:

After the acrylic part has solidified, the mold is opened, and the part is ejected using mechanisms like air blasts or ejector pins. The part may then undergo additional post-processing, such as trimming or polishing.

7. Post-Processing and Finishing:

After mold ejection, the parts often require trimming to remove excess material or flash left from the molding process. Sanding and polishing are commonly used to eliminate surface imperfections such as tool marks, rough edges, or minor scratches, restoring the acrylic’s characteristic clarity and gloss. Techniques like vapor polishing or flame polishing can further smooth and brighten surfaces by slightly melting the acrylic, producing a high-quality finish.

Acrylic Molding Design Guidelines

Designing parts for PMMA molding demands precision. It is essential to consider the material’s unique properties to ensure manufacturability and performance.

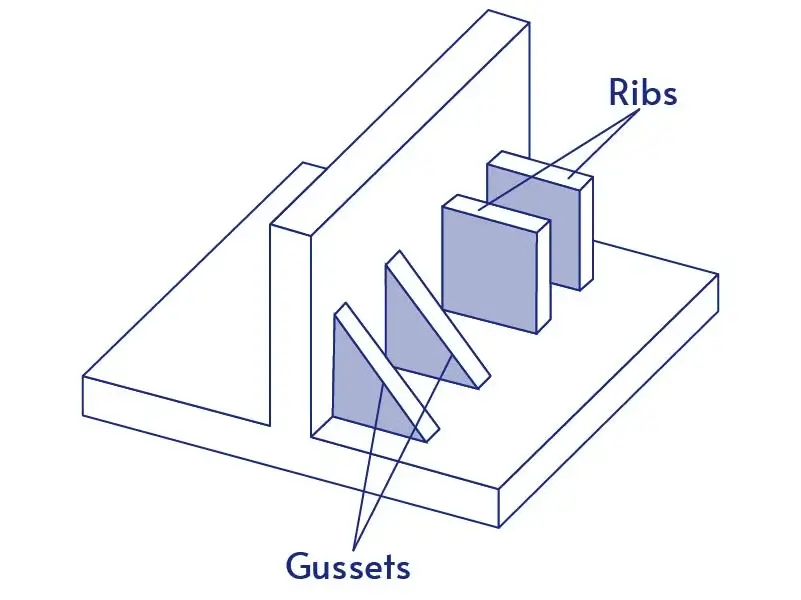

- Wall Thickness: Maintain uniform thickness of 0.025–0.150 inches (0.635–3.81 mm) to prevent warping or sink marks. Gradual transitions for varying thicknesses reduce stress.

- Draft Angles: Due to acrylic’s rigidity and brittleness, proper draft angles (typically ≥1° for smooth surfaces and higher for textured surfaces) are required to facilitate ejection and prevent sticking.

- Radii: Sharp corners concentrate stress and can cause cracking in acrylic parts. Use corner radii at 25–60% of wall thickness to minimize stress concentrations and improve material flow during acrylic injection molding.

- Gate Placement: Strategic gate placement and runner design ensure smooth, uniform flow of molten acrylic, minimizing weld lines, air traps, and flow hesitation. Use larger gates for thicker parts to ensure even filling.

- Post-Molding Considerations: Due to acrylic’s susceptibility to stress cracking, parts often require annealing after molding to relieve internal stresses. Surface finishing techniques such as polishing or coating can enhance scratch resistance and optical quality.

Common Defects and How to Avoid Them

Acrylic injection can encounter defects that compromise part quality, but proactive measures ensure flawless results. Common issues include:

- Bubbles/Cloudiness: Caused by moisture in pellets. Solution: Dry pellets thoroughly (moisture <0.04%) at 80–90°C for 3–5 hours before PMMA molding.

- Burn Marks: Result from excessive PMMA injection molding temperature (>270°C) or fast injection speeds. Solution: Lower melt temperature and use multi-stage injection (slow-fast-slow).

- Warpage/Sink Marks: Stem from uneven cooling or thick walls. Solution: Ensure uniform wall thickness, increase holding pressure, and extend cooling time.

- Flow Lines: Caused by improper gate placement or rapid injection. Solution: Optimize gate location and control injection speed to ensure smooth flow.

- Flashing: Occurs due to high injection pressure or poor mold fit. Solution: Reduce pressure (800–1500 psi) and verify mold alignment.

Applications of Acrylic Injection Molding for Durability and Transparency

Acrylic (PMMA) injection molding ensures outstanding durability and optical clarity across a wide range of industries, meeting both aesthetic and performance requirements.

Medical and Healthcare

PMMA’s biocompatibility, chemical resistance, and superior clarity make it ideal for medical devices such as syringes, IV connectors, surgical instruments, and diagnostic equipment. Its optical transparency enables healthcare professionals to monitor fluids accurately, while the material’s durability withstands repeated sterilization cycles without degradation, ensuring consistent performance in critical environments.

Consumer Electronics

In consumer electronics, acrylic injection molding delivers sleek, durable, and visually appealing components. Its scratch resistance and high transparency are perfect for smartphone screens, LED light covers, and audio device housings. The material’s versatility allows for different surface finishes, enhancing both aesthetics and long-term reliability.

Other Industrial Applications

Beyond healthcare and electronics, PMMA is used in automotive lighting, architectural panels, and optical lenses where a balance of strength, clarity, and precision manufacturing is required. Injection molding ensures consistent quality even in complex, high-volume production.

Conclusion

Acrylic is a common plastic material used in injection molding, but it is hygroscopic; inadequate drying or improper processing methods will add costs and defects. Jiangzhi is an experienced injection molding service manufacturer. We supply professional Acrylic injection molding service. Welcome to contact us for an Acrylic injection molding solution.

FAQ About Acrylic Molding

Yes, acrylic parts can be colored or tinted using dyes or additives during PMMA injection molding.

Acrylic injection requires thorough pre-drying due to PMMA’s hygroscopic nature.

Acrylic plastic molding supports glossy, matte, or textured finishes via polishing, sanding, or mold texturing.

Costs vary by part complexity, mold design, and volume. For precise pricing, consult a PMMA molding specialist with us.