Injection molding is a widely used manufacturing process, but understanding the injection molding price is essential for optimizing production budgets. Various factors impact plastic injection molding costs, from tooling expenses to material selection. This guide covers key cost components, calculation methods, and strategies to minimize injection molding manufacturing costs.

Key Factors Influencing Injection Molding Cost

Equipment and Machine Costs

The type and size of an injection molding machine significantly influence production costs. High-tonnage machines are required for larger parts, while precision molding machines are needed for intricate designs, both of which increase molding costs per part.

Mold Design and Tooling Costs

- Mold complexity: Features like undercuts, thin walls, and complex geometries raise plastic mold manufacturing costs.

- Mold material: Steel molds have a higher upfront tooling cost for injection molding but offer long-term durability, while aluminum molds are more cost-effective for low-volume production.

- Cavity count: Multi-cavity molds reduce per-unit injection moulding cost by increasing output per cycle.

Raw Material Costs

- Plastic resin selection: High-performance engineering plastics (e.g., PEEK, Ultem) cost more than common thermoplastics like ABS and PP.

- Material waste: Poor material flow or excessive sprues and runners increase plastic manufacturing costs.

Production Volume and Cycle Time

Production volume is a key factor in determining injection molding price. Low-volume runs (100–1,000 parts) typically use affordable rapid tooling or 3D-printed molds, with higher per-part costs due to manual labor and limited automation. Medium-volume production (5,000–10,000 parts) involves more durable aluminum or pre-hardened steel molds, offering better cost efficiency per part. High-volume runs (100,000+ parts) require robust steel molds and advanced machinery, but significantly reduce the cost per unit thanks to economies of scale. While upfront mold costs increase with volume, the per-part cost decreases, making high-volume production the most cost-effective option in the long run.

Cycle time—the time it takes to complete one molding cycle—directly affects production efficiency. Materials, part design, wall thickness, and cooling systems all influence cycle time. Shorter cycles improve output and reduce per-part labor and machine costs, while longer cycles increase overall production time and expenses. Optimizing part design and mold cooling is essential for balancing speed, quality, and cost.

Injection Molding Additive Costs

Additives are essential in injection molding to enhance material performance, but they also impact costs. Common types include colorants, UV stabilizers, flame retardants, impact modifiers, and glass fibers. Basic additives like color masterbatch add minimal cost, while high-performance options such as flame retardants or reinforced fillers can significantly raise material prices and affect processing, like cycle time and mold wear.

The additive loading ratio also matters—higher levels (e.g., 30% glass fiber) mean higher material cost and potential design adjustments. For large production runs, even small additive costs per kg can lead to substantial total expenses. Choosing the right additives based on performance needs and cost-efficiency is key to optimizing the overall molding process.

Labor and Overhead Costs

Labor-intensive post-processing, such as assembly, surface finishing, and quality control, contributes to the overall injection molding manufacturing cost.

How to Calculatethe Cost of Injection Molding?

Understanding how to calculate injection molding price requires analyzing both fixed and variable costs.

Fixed Costs

- Injection mold cost: One-time investment in mold fabrication, significantly impacting the low-volume injection molding cost.

- Machine setup cost: Includes programming and initial calibration.

Variable Costs

Material costs: Depend on resin type, colorants, and additives.Cycle time and production efficiency: Faster cycles lower injection molding pricing per unit.

Labor and secondary operations: Assembly, finishing, and packaging add to the final plastic injection molding cost.

Cost Impact of Production Volume

For low-volume production, prototype injection molding part cost can be high due to tooling expenses, whereas large production runs significantly reduce molding cost per unit.

Injection Molding Cost Breakdown & Optimization Strategies

Injection molding can be an expensive process. However, there are several strategies manufacturers can employ to get low-cost injection molding without compromising part quality or performance. Understanding the cost structure of injection molding is essential for making informed decisions and optimizing production.

1. Optimizing Mold Design

- Simplify part geometries to lower mold-making costs.

- Use multi-cavity or family molds to improve efficiency.

- Choose aluminum molds for low-volume plastic injection molding to save on molding tooling costs.

2. Select Cost-Effective Materials

- Balance material properties with injection molding part cost considerations.

- Recycle and reuse plastic waste to reduce raw material expenses.

Comparison Table (Title: Injection Molding Cost by Material 2024)

| Material | Price ($/kg) | Applications | Cost-Saving Tips |

|---|---|---|---|

| PP | 1.2–1.8 | Consumer product housings | Reduce wall thickness to optimize fill rate |

| ABS | 2.0–2.5 | Electronic components | Use 10–30% recycled pellets |

| PC | 4.5–6.0 | Medical/Automotive high-strength parts | Avoid overcooling to shorten cycle time |

3. Resin and Additive Costs

Material selection has a significant impact on overall cost. Commodity resins like PP or PE are affordable, while engineering plastics such as PC or PEEK are more expensive due to superior mechanical properties. Additives (e.g., UV stabilizers, colorants, flame retardants) can further increase cost but are essential for meeting specific application needs. Optimizing material usage and considering regrind options where possible can help control expenses.

4. Production Volume & Unit Cost

Production volume is directly related to unit cost:

- Low-volume (100–1,000 parts): Often involves prototype or short-run parts. Using rapid tooling or 3D printed molds minimizes upfront cost. Though per-part cost is higher (approx. $4.5/part), it suits small-batch needs.

- Mid-volume (5,000–10,000 parts): Suitable for aluminum or pre-hardened steel molds. Offers a balance between tooling cost and unit price, around $3/part.

- High-volume (100,000–300,000+ parts): Ideal for hardened steel molds and full automation. Although tooling may cost $25,000–$75,000, the unit price drops to as low as $1.75 due to economies of scale.

5. Cycle Time and Efficiency

Shorter cycle times lead to more parts produced per hour, reducing labor and machine costs. Factors affecting cycle time include part design, material selection, mold cooling efficiency, and the use of automation. Optimizing wall thickness, avoiding sharp corners, and using efficient gating systems are practical ways to shorten cycles.

6. Use Low-Cost Manufacturing Locations

- Offshore production can reduce plastic injection molding costs, but logistics and quality control must be managed.

7. Practical Cost-Saving Tips

To reduce injection moulding costs without compromising quality, consider the following strategies:

- Define your tooling budget early: Align expectations with manufacturers based on your production goals.

- Work with reputable suppliers: They offer better mold maintenance and longer tool life, ensuring consistent quality over time.

- Reuse and recycle plastic scrap: Limited regrind use can cut costs, though mechanical properties may gradually degrade after several cycles.

- Pre-order critical components: Helps avoid delays and unexpected repair costs.

- Streamline your part design: Focus on essential features and minimize unnecessary aesthetics or surface finishes.

- Consider insert molding: A cost-effective way to integrate metal or threaded parts during molding, reducing assembly time and tooling needs.

8. Tailored Cost Optimization by Production Scale

| Production Scale | Key Strategy | Cost Benefit |

|---|---|---|

| Low-Volume | Use rapid tooling or 3D printed molds | Low startup cost |

| Medium-Volume | Optimize mold design and use regrind | Balanced cost per unit |

| High-Volume | Invest in durable molds and automation | Lowest unit cost |

Cost Variations Across Different Applications

The injection molding costs can vary significantly depending on the type of product being manufactured. Different industries and applications have distinct requirements, which affect not only the materials and manufacturing techniques used but also the design complexity and tooling.

Consumer Goods

Low-cost thermoplastics like PP and ABS dominate, keeping the consumer goods injection molding price low.

- Materials: Consumer goods typically use cost-effective plastics such as polypropylene or ABS, which are widely available and easy to process. These materials help lower overall injection molding cost, making the process suitable for mass production.

- Part Complexity: While many consumer goods parts have simple geometries, others may include intricate features such as snaps or inserts. Simple designs lower the injection molding price, but complex parts require more sophisticated tooling and mold design, driving up cost.

- Production Volume: High-volume production is common in the consumer goods sector, which allows for economies of scale. This reduces the cost per unit significantly, as the fixed costs of mold design and setup are spread across a larger number of parts.

Medical Devices

Strict regulatory requirements and specialty materials raise medical injection molding costs.

- Materials: Medical devices often require medical-grade plastics that meet specific regulatory standards, that tend to be more expensive than standard consumer-grade plastics.

- Part Complexity: Medical devices often require more complex geometries and tighter tolerances to ensure functionality and safety.

- Production Volume: Although some medical device manufacturers operate at high volumes, many projects involve lower-volume, specialized runs.

Automotive Parts

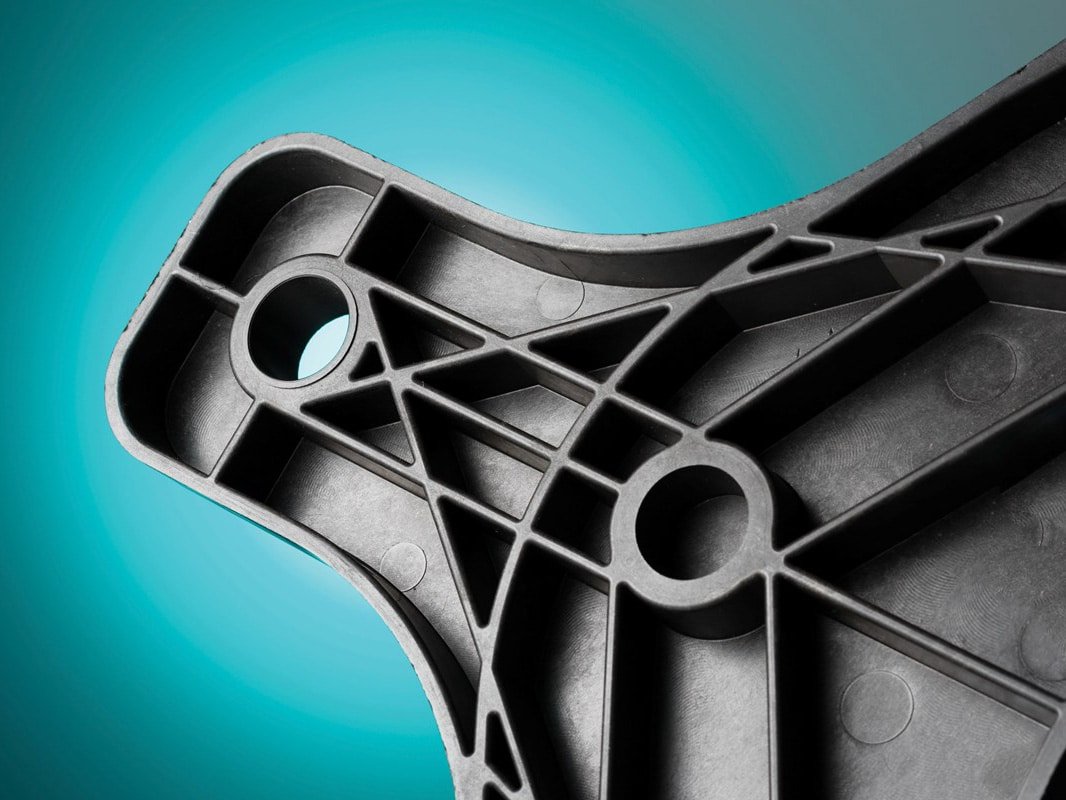

High-strength polymers and large molds increase automotive injection molding cost, but high production volumes offset expenses.

- Materials: Automotive parts often require high-strength plastics or composites, such as nylon, polycarbonate, and PBT. These materials offer durability and resistance to heat, chemicals, and wear, but tend to be more costly than standard injection molding resins.

- Part Complexity: Automotive parts often have highly detailed and intricate designs, such as undercuts, complex geometries, and reinforcement features. The need for high precision and the incorporation of metal inserts or additional components can increase the injection moulding cost.

- Production Volume: The automotive industry typically involves high-volume production, which benefits from economies of scale. However, the high precision and quality standards required for these parts can make tooling more expensive and necessitate additional inspection and testing procedures.

Electronics

Precision molding and heat-resistant plastics increase electronic component injection molding costs.

- Materials: Electronics parts require materials that are not only cost-effective but also offer high electrical insulation properties, durability, and resistance to heat and chemicals. Additionally, materials used in electronic components often need to meet specific fire-resistance or environmental regulations, which can increase the injection molding cost.

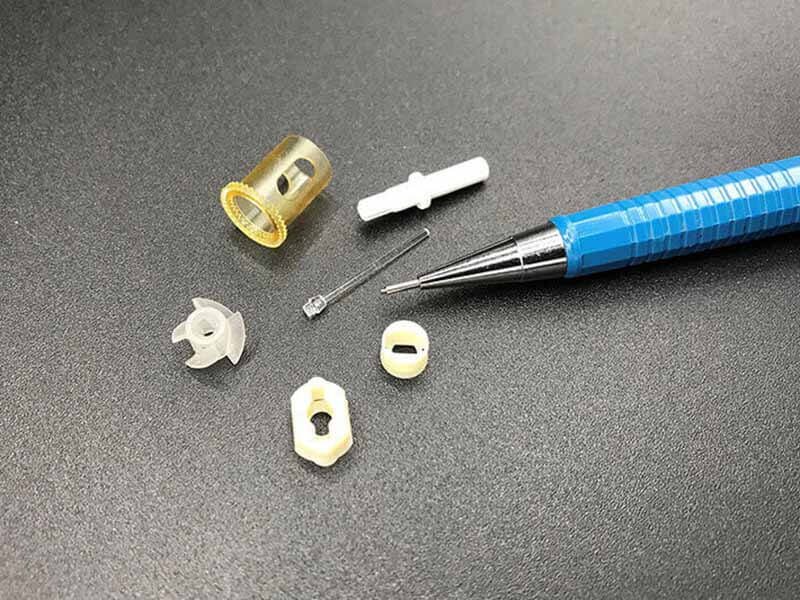

- Part Complexity: Electronic components tend to have intricate designs that require high precision, such as thin walls, small cavities, and complex internal features. This increases the complexity of the mold design and manufacturing process, leading to higher tooling and labor costs.

- Production Volume: The electronics industry is characterized by both high-volume production (e.g., mobile phone casings) and low-volume, highly customized runs (e.g., specialized connectors). For high-volume runs, the injection molding price per unit tends to decrease, but low-volume projects often involve higher cost due to the need for specialized molds and testing.

Getting an Accurate Injection Molding Costs Quote

When requesting a plastic injection molding quote, ask the following:

- What mold material do you use, and how does it affect mold tooling cost?

- Do you offer multi-cavity molds to reduce injection molding per unit cost?

- Can you provide low-cost injection molding options for prototypes?

- Do you offer secondary processes like surface finishing and assembly?

Conclusion

Understanding the cost of injection molding is crucial for manufacturers aiming to optimize budgets. By considering tooling expenses, material selection, and production volume, businesses can reduce plastic costs of injection molding per part while maintaining quality.