Injection molding delamination is a vexing issue that occurs in injection-molded parts and is classified as one of the common injection molding defects. The causes of delamination vary, often involving material incompatibility, improper processing conditions, or contamination. In this article, we will examine the primary causes of injection molding delamination and offer effective prevention methods to help you minimize such defects and enhance product quality.

What is Injection Molding Delamination?

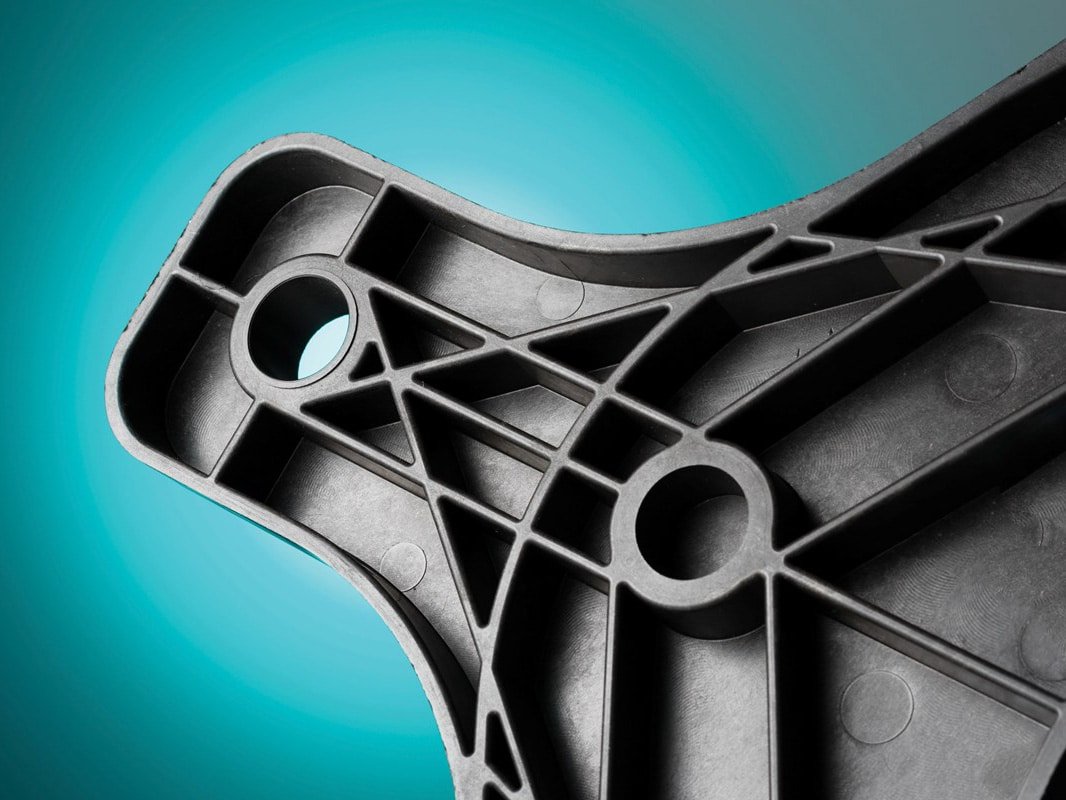

Injection molding delamination refers to the separation or peeling of layers within a plastic part, either at the surface or internally. This phenomenon occurs when the polymer layers do not adhere correctly, resulting in weak spots that jeopardize the product’s mechanical strength and durability. This defect can arise during the molding process itself or due to post-processing stresses.

Common Causes of Delamination in Plastic Injection Molding

Delamination in plastic injection molding can emerge from various sources.

Material-Related Issues

- Contaminated Resins: Foreign substances—be it dust, grease, or incompatible polymers—can infiltrate the molten plastic. These contaminants disrupt the molecular bonding, leading to layer separation and delamination in injection molding.

- Incompatible Polymers: In processes like double-shot molding or overmolding, pairing resins with poor chemical affinity results in weak interlayer bonds.

- Excessive Moisture: Hygroscopic resins, if not thoroughly dried before molding, transform into steam under high temperatures, creating voids or blisters that manifest as surface delamination in injection molding.

Processing Faults

Improper molding parameters can induce delamination in injection molding.

- Incorrect Mold Temperature: Too low a temperature causes premature cooling, leading to shrinkage and stress that trigger injection molding delamination.

- Inadequate Injection Speed: A sluggish injection speed causes uneven filling or splaying.

- Insufficient Hold Time: Short hold times prevent the material at the part’s surface from cooling adequately, leading to excessive shrinkage stress.

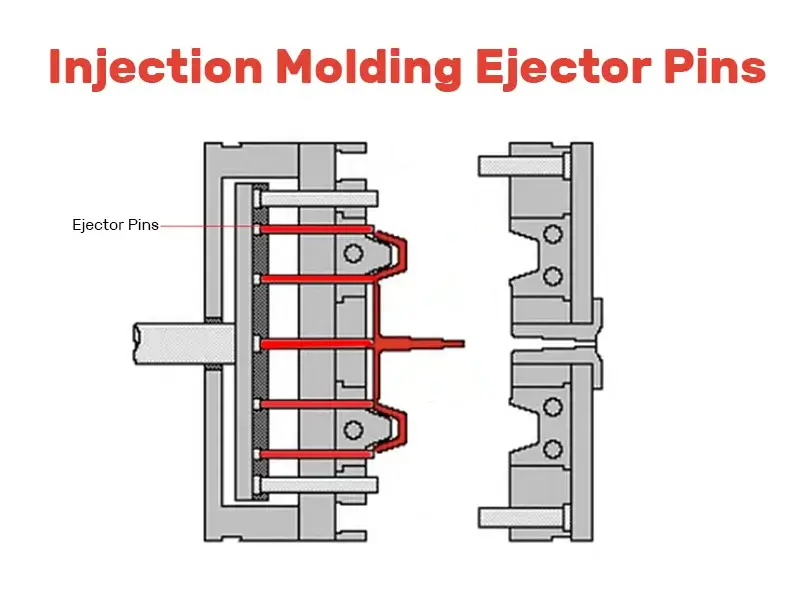

Machinery and Mold Design Errors

The molding equipment and mold design play pivotal roles in ensuring part quality. Flaws in these components can precipitate delamination in injection molding:

- Improper Gate and Runner Design: Sharp runner radii or undersized gates create turbulent flow or premature hardening of the resin, leading to delamination in plastic injection molding.

- Insufficient Cushioning: Inadequate pressure buffering at the gate fails to force the material fully into the mold cavity, resulting in weak layer bonding and surface delamination in injection molding.

- Excessive Mold Release Agents: Over-application of release agents can lead to pinhole defects or delamination in injection molding.

How to Prevent and Resolve Delamination in Injection Molding?

To prevent and solve delamination issues in injection molding, it is essential to control key process parameters, such as increasing mold and melt temperature, to ensure better material flow and reduce premature cooling, which helps avoid poor bonding between layers. Optimizing injection pressure and speed can minimize shear stress that causes material separation, while mold design improvements like wider gates and better venting enhance material flow uniformity.

Additionally, using high-quality, uncontaminated raw materials and maintaining equipment cleanliness helps prevent defects. Comprehensive adjustments in material selection, mold design, and processing conditions, combined with trial verification, effectively address delamination problems.

Conclusion

Injection molding delamination is a challenge, but not an insurmountable one. When delamination occurs, with experience and expertise, delamination in plastic injection molding can be prevented. Jiangzhi has experience in injection molding and is a professional material expert. Welcome to contact us to get a custom injection molding service solution.