Warping in injection molding is a common defect that affects the quality and functionality of plastic parts. One of the primary causes of warpage is uneven shrinkage in injection molding during cooling, which creates internal stresses and leads to deformation. This article explores the nature of warpage, its causes, and practical solutions to prevent it, ensuring the production of reliable and high-quality plastic components.

What is Injection Molding Warpage?

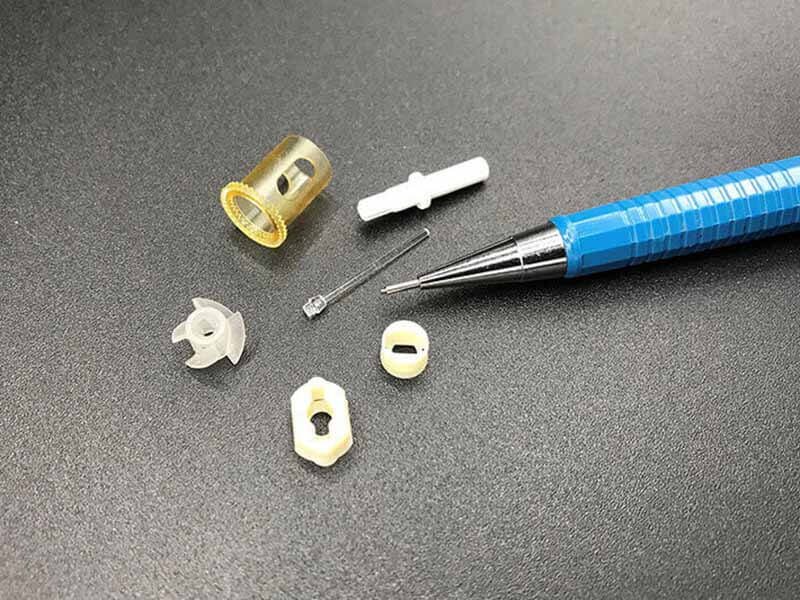

Warpage in injection molding refers to the unintended deformation of a plastic part after it is ejected from the mold, where the part’s shape deviates from the mold cavity’s design. This defect manifests as bending, twisting, or bowing. Warping in injection molding is particularly common in complex geometries, thin-walled parts, or components with varying thicknesses.

Causes and Solutions of Warping in Injection Molding

Warping in injection molding can arise from multiple sources. Each cause can often be addressed with targeted solutions. Below are the primary factors leading to warpage, along with practical ways to mitigate them.

Uneven Cooling

Uneven cooling is a leading cause of injection molding warping. When different sections of a part cool at varying rates, differential shrinkage occurs, creating internal stresses that deform the part.

Design molds with uniform cooling channels to ensure consistent heat dissipation across the part. Implement conformal cooling systems that follow the part’s geometry, promoting even cooling for complex shapes. Extend cooling time to allow the part to solidify fully before ejection, preventing premature deformation.

Material Properties

Material properties heavily influence shrinkage behavior and warpage. Semi-crystalline plastics exhibit higher shrinkage rates than amorphous plastics. Additionally, fiber-reinforced materials can cause uneven shrinkage due to fiber orientation during material flow, leading to localized stresses and warpage. Improper material drying can also introduce moisture, further contributing to injection molding warping.

Select low-shrinkage amorphous plastics for precision parts where dimensional stability is critical. Control fiber orientation in reinforced plastics by optimizing gate placement to ensure uniform material flow. Ensure thorough material drying before molding to eliminate moisture-related defects.

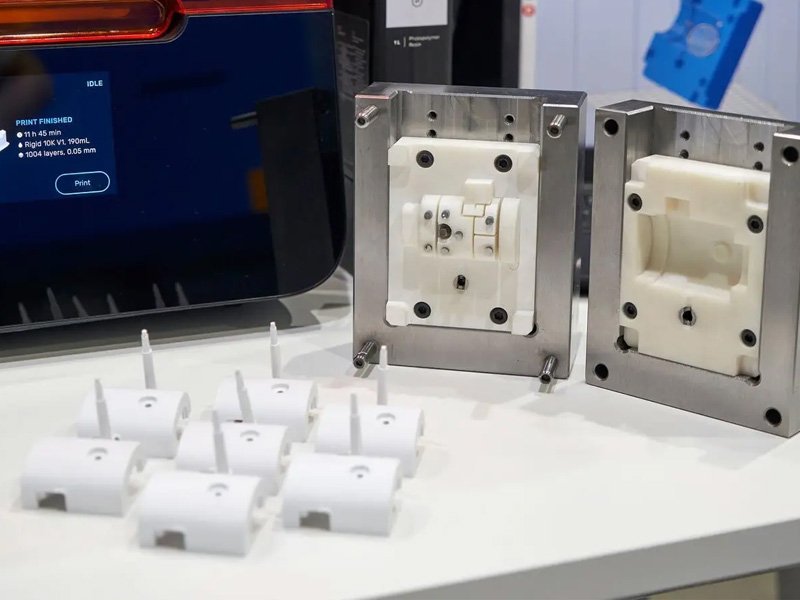

Improper Mold Design

Poor mold design is a common culprit behind injection molding warping. Inadequate gate placement, insufficient gate size, or uneven wall thickness can disrupt material flow and cooling, leading to localized shrinkage and warpage.

Solutions: Optimize gate location, placing gates at the mold’s pressure center to ensure uniform material flow and minimize warping in injection molding. Use multiple gates or film gates for large or complex parts to reduce flow length and promote balanced filling. Maintain uniform wall thickness with smooth transitions to avoid stress concentrations.

Incorrect Processing Parameters

Inconsistent or incorrect processing conditions during injection molding can lead to warping. High injection pressure, improper melt temperature, or insufficient holding time can induce stresses or uneven filling, leading to warpage.

Solutions: Adjust injection pressure and speed to achieve smooth, uniform material flow, reducing internal stresses. Maintain melt temperature within the resin’s recommended range to ensure proper viscosity and flow behavior. Optimize holding pressure and time to compensate for shrinkage during cooling, minimizing injection molding warping.

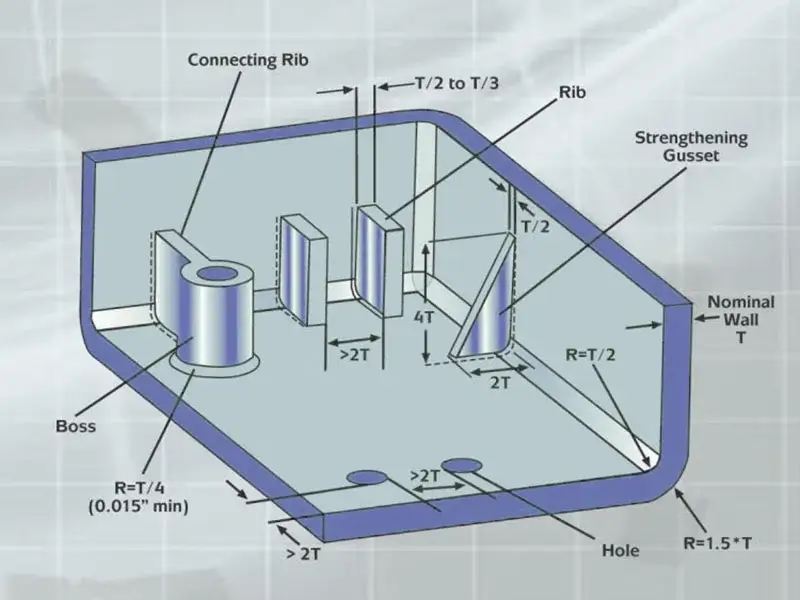

Part Design Flaws

Non-uniform wall thickness, sharp corners, or the absence of reinforcing ribs increase stress concentrations and uneven shrinkage.

Ejection System Issues

An imbalanced ejection system or premature ejection can cause warping in injection molding. If ejector pins apply uneven force or the part is ejected while still hot, it may deform, especially in areas with high ejection resistance.

Solutions: Design a balanced ejection system with adequately sized and strategically placed ejector pins to ensure uniform force application. Ensure parts are fully cooled before ejection to avoid deformation under stress. Regularly inspect and maintain ejection mechanisms to prevent misalignment or wear.

Choose JiangZhi as Your Plastic Injection Molding Supplier

Warping in injection molding is a complex challenge, but JiangZhi is a trusted partner in overcoming it. The professional team provides expert plastic part design suggestions to eliminate warping in injection molding and other quality defects by using advanced tools like Autodesk Moldflow. Welcome to contact Jiangzhi to get comprehensive design guidance and an injection molding solution.