CNC Polystyrene Machining Service

PS CNC Machining Service

At Jiangzhi, we specialize in polystyrene CNC machining service using advanced PS CNC equipment. Whether you’re working on functional prototypes or custom PS parts for end-use applications, our team ensures each CNC polystyrene component is dimensionally stable, cleanly cut, and ready to perform. With deep experience in machining polystyrene, we can produce complex geometries, thin walls, and detailed internal features efficiently.

Common PS CNC parts applications include: Electronics (housings, insulation mounts). Display and signage (transparent panels, fixtures), Consumer goods (lightweight structural parts), Education and modeling (prototype structures, academic models). From design to delivery, Jiangzhi ensures your polystyrene machined parts meet both technical and budget expectations.

| Price | $$$ |

|---|---|

| Tolerances | ±0.02mm |

| Maximum Part Size | 700mm x 500mm x 200mm |

| Minimum Feature Size | Φ 0.8mm |

| Wall Thickness | 0.8mm |

| Lead Time | About 3-6 days |

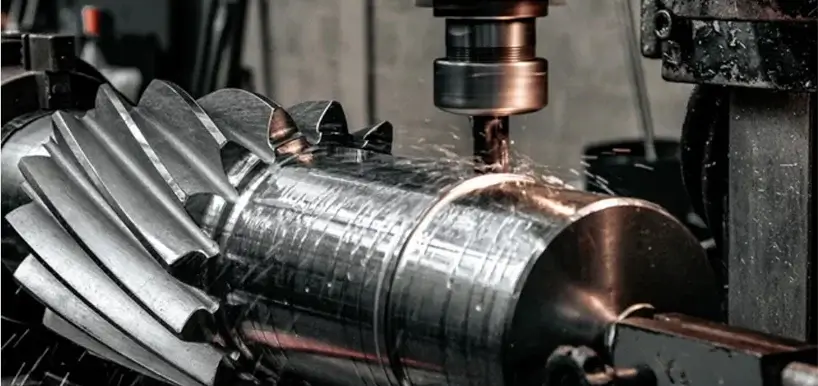

PS CNC Machining Parts Process

At Jiangzhi, our polystyrene CNC machining technology uses advanced equipment for precise cutting, milling, and shaping, ensuring exceptional dimensional accuracy and smooth surface finishes. We offer two popular machining methods:

Polystyrene CNC Milling

Polystyrene CNC Turning

Polystyrene Machining Plastic Properties

Polystyrene (PS) CNC machining is valued for its clean machinability, dimensional stability, and affordability. While more brittle than some engineering plastics, PS performs well under the right fixturing and delivers reliable results for precise, lightweight components.

- GPPS – A transparent, rigid plastic with high stiffness and easy molding, but brittle and low impact resistance, used for food containers, clear boxes, and stationery.

- HIPS – An opaque, smooth-surfaced plastic with improved toughness and impact resistance but low transparency, used for refrigerator linings, TV housings, and toys.

- EPS – A lightweight white foam with good insulation and cushioning, but low strength and solvent-sensitive, used for packaging, disposable food containers, and building insulation panels.

| Tensile Strength, Yield (MPa) | Elongation at Break | Hardness | Impact Strength | Heat Deflection | Heat Deflection Temperature | Melting Point |

|---|---|---|---|---|---|---|

| 35–55 MPa | 1–3% | R110–R120 | 10–30 J/m | 90–100°C | 80–90°C | No true melting point; softens at about100°C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Related Process

Want Clear, Lightweight CNC Polystyrene Parts?

Advantages & Application of CNC Polystyrene

-

Advantages of PS CNC Machining

- Excellent chemical resistance – withstands corrosive chemicals and solvents.

- Low friction and non-stick surface – ideal for sliding or sealing components.

- High thermal stability – suitable for a wide temperature range.

- Good machinability – machines cleanly with precision.

- Electrical insulation – great for electronic components.

-

Polystyrene Machining Parts Application

- Electronics Industry – Insulating parts, electronic prototypes, small housings.

- Automotive Industry – Prototype panels, interior components, mock-up parts.

- Construction & Architecture – Scale/architectural models, decorative panels.

- Advertising & Signage – Signboards, 3D letters, display props.

- Education & Design – Student models, DIY projects, small custom pieces.

Surface Finishing Options for Polystyrene CNC Parts

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Jiangzhi PS CNC Machining Parts Are Guaranteed

FAQs About CNC Polystyrene Machining

Yes, PS machining is effective for lightweight, low-cost parts with good dimensional accuracy.

GPPS offers better clarity, while HIPS adds impact resistance. We machine both based on your needs.

Yes, with proper fixturing, we can produce intricate details and thin features in polystyrene.

Yes. We follow strict safety and ventilation protocols, especially when machining high-speed.

Absolutely. Our engineers offer DFM (Design for Machining) feedback to help optimize your part.