In the field of plastic processing, extrusion molding vs injection molding are two common methods. Extrusion molding produces continuous profiles with uniform cross-sections, while injection molding forms discrete parts with complex geometries. These processes differ in equipment, production flow, and suitable applications. This article examines each method, compares them directly, and provides criteria for selection.

What is Injection Molding?

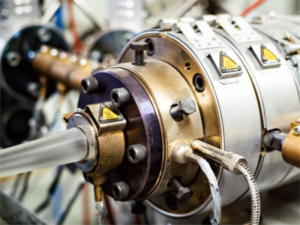

Injection molding service is a manufacturing process used to produce complex plastic components with high precision and repeatability. The process starts by feeding thermoplastic pellets into a heated barrel. A rotating screw melts the material and builds up pressure, then pushes the molten plastic into the mold cavity through a nozzle. After the material cools and hardens, the mold opens, and the finished part is ejected. This cycle repeats rapidly, making injection molding an efficient method for large-scale production.

Injection molding is widely used in industries such as automotive, medical devices, electronics, and consumer goods, where accuracy and consistency are critical.

Advantages of Injection Molding

- High-dimensional accuracy and excellent repeatability.

- Capable of producing complex geometries and fine details.

- Suitable for mass production with consistent quality.

- Allows multi-cavity molds for increased output in a single cycle.

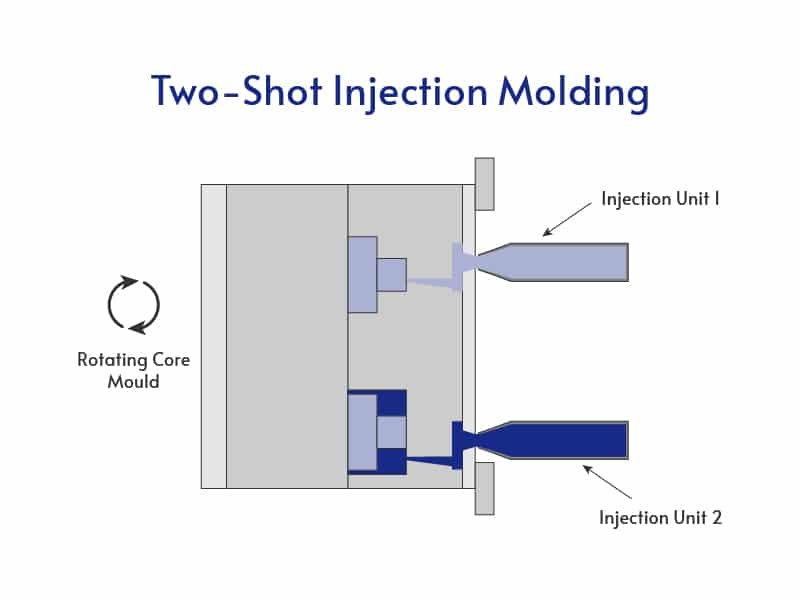

- Integrates features like inserts or overmolding in one step.

- Offers a wide selection of materials, including thermoplastics and thermosets.

Disadvantages of Injection Molding

- High initial investment for mold fabrication.

- Long lead time before mass production begins.

- Limited cost efficiency for small production runs.

- Involves long lead times for mold fabrication, typically 4 to 12 weeks.

What is Extrusion Molding?

Extrusion molding, also called extrusion forming, is a continuous manufacturing process used to produce long, uniform plastic profiles. Unlike injection molding, which creates discrete parts, extrusion produces continuous shapes such as pipes, tubes, sheets, and films.

The process begins by feeding thermoplastic granules into a heated barrel where they are melted by a rotating screw. The molten plastic is then forced through a die, which defines the cross-sectional profile of the final product. As the material exits the die, it cools gradually, often through a water bath or air cooling system, before being cut to the required length or wound onto rolls.

Advantages of Extrusion Molding

- Continuous process suitable for high-volume production.

- Lower tooling costs compared to injection molding.

- High material efficiency with minimal waste.

- Consistent cross-sectional profiles.

Disadvantages of Extrusion Molding

- Limited to uniform shapes with fixed cross-sections.

- Requires post-processing like cutting, drilling, or bending for finished parts.

- Surface finish may require post-processing.

- Needs space for long production lines.

- Not suitable for complex or intricate parts.

Extrusion Molding vs Injection Molding

Both extrusion vs injection molding processes transform molten plastic into solid shapes, but their approaches, capabilities, and end products are distinct. The following table summarizes the difference between extrusion and injection molding across several key aspects.

| Aspect | Injection Molding | Extrusion Molding |

|---|---|---|

| Process and Equipment | Cyclic: melt injection into closed mold, cool, eject. Requires injection machine, multi-part molds. | Continuous: melt through die, calibrate, cool, pull. Uses extruder, die, cooling line. |

| Tooling | High-precision steel molds with multiple cavities. | Simple die with a fixed cross-section. |

| Product Type | Individual, discrete parts. | Continuous profiles (pipes, sheets, films). |

| Design Flexibility | Supports 3D complex shapes, undercuts, threads, inserts. | Restricted to 2D uniform profiles; secondary operations for variations. |

| Cost and Scale | High initial mold cost; economical above 5,000 units. Per-part cost decreases with volume. | Low die cost; suitable for 100,000+ meters. Low cost per meter in high volumes. |

| Material Compatibility | Broad range of thermoplastics; easy material switches with mold cleaning. | Best for high-flow materials; longer cleanup for switches. |

| Surface Finish | Excellent finish directly from the mold. | May need additional surface treatment. |

| Production Efficiency | Cycle time 10–60 seconds per shot; high automation. | Continuous operation; output based on line speed (e.g., 50–100 m/min). |

| Typical Tolerances | ±0.01–0.05 mm. | ±0.1–0.5 mm on cross-section. |

Conclusion: How to Choose with Extrusion and Injection Molding?

Choosing the right manufacturing process depends on key factors such as product design, production volume, budget, and performance needs. While extrusion is ideal for producing continuous profiles, injection molding excels at creating precise and complex parts. By carefully evaluating these factors, you can select the method that best supports your project goals.

Jiangzhi provides professional injection molding services customized to your specifications. Contact us today to get a tailored molding solution.