In modern mechanical design and manufacturing, even the smallest design features can significantly influence performance, assembly, and cost efficiency. Threaded holes create internal threads to accept bolts or screws, and tapped holes are a specific type of threaded hole. Despite this relationship, many people often confuse the two. This article examines definitions, key differences, selection criteria, and best practices for tapped holes vs threaded holes. Understanding these elements helps ensure better decisions in product design, manufacturing, and overall project execution.

What Is a Threaded Hole?

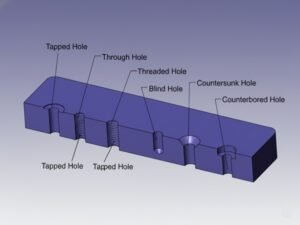

A threaded hole is a hole in a part that contains internal helical threads, allowing it to securely receive a matching bolt or screw. These threads create a reliable mechanical connection that can withstand torque and vibration while enabling easy assembly and disassembly. Threaded holes are essential in many mechanical and structural applications where detachable fastening is required. Threaded holes can be created using several methods, including taps and dies, thread rolling, thread milling, single-point threading, casting or molding, and thread inserts.

Threaded holes are used in automotive parts, aerospace brackets, electronic enclosures, and construction components. They provide reliable, removable fastening that can withstand vibration and heavy loads.

What is a Tapped Hole?

A tapped hole is created by using a tap tool to cut or form internal threads inside a pre-drilled hole. This method is common in medium- to low-volume production where precise and repeatable fastening is required. It is often used in parts that need frequent assembly and disassembly, such as medical devices, electronics housings, and mechanical panels, where threads handle moderate torque without requiring deep engagement. During tapping, the tool rotates into the hole with lubrication to remove chips and prevent damage. Compared with other threading methods, tapping offers speed and consistency, but it is more limited in depth and material range.

What Are the Tap Types?

Different types of taps are designed to suit various hole depths, materials, and machining needs:

- Taper Tap: Has about 9 threads of gradual chamfer for easy starting and alignment, ideal for through holes or the first stage of blind hole cutting.

- Plug Tap: Includes around 5 chamfered threads, offering balanced cutting performance for most general-purpose or mid-depth blind holes.

- Bottoming Tap: Has only 1–2 chamfered threads, used to cut full threads to the bottom of blind holes after a taper or plug tap.

- Spiral Flute Tap: Features helical flutes that lift chips upward, preventing clogging and making it suitable for blind holes.

- Thread Forming Tap: Creates threads by displacing material instead of cutting, producing strong, chip-free threads in ductile metals like aluminum.

Tapped Hole vs Threaded Hole: Key Differences

Process Perspective

Tapped holes require a pre-drilled hole followed by thread cutting, involving sequential steps (drill-tap-clean chips) and limited to internal applications. Threaded holes offer flexible processes, including direct milling or rolling without pre-drilling, supporting both internal and external threads with custom forms.

Tooling Perspective

Tapping relies on specialized taps (taper, plug), which dull quickly and need frequent replacement. Threaded holes use varied tools, such as end mills, rolling dies, or inserts, accommodating complex geometries with greater durability.

Material Perspective

Tapping causes rapid tool wear in hard materials like quenched steel and chip adhesion in soft or ductile ones like brass. Threaded holes optimize compatibility through rolling or milling for both hard and soft materials, reducing defects.

Design Geometry Perspective

Tapping is restricted to standard pitches and blind hole depths due to the chamfer space, without support for variable pitches. Threaded holes allow design freedom, including deep blind holes, external threads, or non-standard customizations, enhancing geometric variety.

Speed Perspective

Tapping completes cycles quickly (10-30 seconds per hole on CNC), fitting small batches. Threaded holes via milling start slower but accelerate in large batches with continuous rolling, with overall efficiency depending on volume.

Cost Perspective

Tapping involves high tool and replacement costs, economical for small scales. Threaded holes require expensive initial equipment like milling machines, but costs are diluted in large batches, with inserts lowering long-term maintenance.

Similarities Between Tapped Holes and Threaded Holes

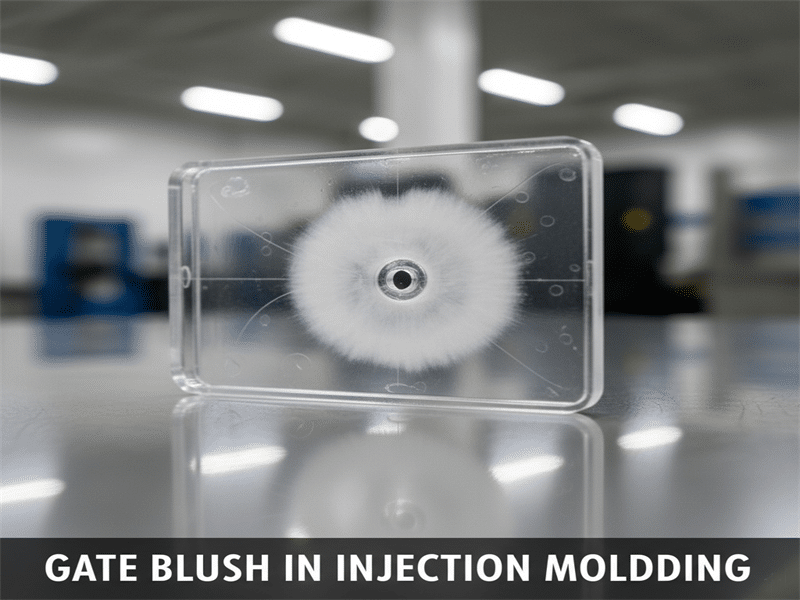

Tapped holes and threaded holes share the primary function of creating internal helical structures for bolt engagement, providing pull-out and torque resistance. Both support blind or through-hole designs and require precise tolerance control. They work with thermoplastic and metal materials and are suited to vibration-prone environments for detachable assemblies. Post-processing for both includes deburring and lubrication, with low waste rates as chips are recycled. In CNC settings, automation levels remain high, easily integrating multi-axis operations for batch consistency. Learn more about injection molding thread.

Conclusion

A tapped hole is a type of threaded hole. All tapped holes are threaded holes, but not all threaded holes are tapped holes. A threaded hole does not always result from tapping and can employ rolling or milling to broaden applications. Clarifying this subset relationship avoids design errors. A thorough understanding aids in selecting the right thread machining method across engineering fields. For projects requiring professional threading solutions, Jiangzhi provides expert injection molding and CNC machining services. Our expertise ensures accurate thread formation, reliable assembly performance, and consistent production quality.